Loading Port:Shanghai

Payment Terms:TT OR LC

Min Order Qty:1 set

Supply Capability:1 set/month

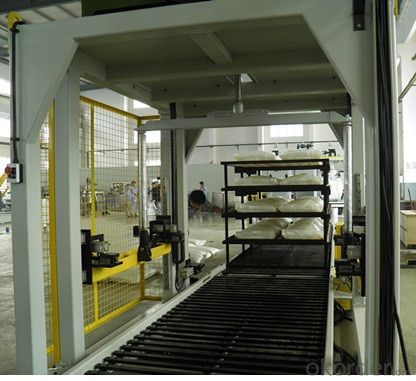

Bag Bitumen Filling Production Line CNBM-40A

I. Application and performance

Coating filling machine is applied to fill coating, paint, ink, lubricant, oil and so on, fine chemical, daily chemical, foodstuff material, pharmacy material, bitumen and so on.

II. Features

Coating filling machine is composed of SS roller conveyor, filling postion, feeding cap, capping, electrical control, pneumatic control and vacuum control. Manual feeds drum at inlet of conveyor, which is conveyed to feeding position, when sensor checks drum, weighing position stays to wait, pusher pushes drum to filling and weighing platform. The sensor checks drum, open filling nozzle and feeding valve automatically, fast filling to set value, feeding valve closes and slow filling, to set value, filling nozzle closes. After feeding cap, pusher pulls the drum to conveyor to feeding cap. When the sensor checks drum, stop it and catch cap rotate then put it on the drum, then to capping position. When capping sensor checks drum also stop it then cap it, after that, capping head resets, orientator releases it to be discharged out.

III. Technical parameter

Filling container (packing materials): 25-40Kg bag

Filling materials: Asphalt (temperature ≤140℃)

Filling speed: 160-180P/hour

Voltage: 380V/220V, 50Hz

Packing line power: 28kW

Filling accuracy Grade 0.2 (±0.2%)

Purified wind pressure 0.5-0.7Mpa

Air consumption (including the empty shelf supply line): 6Nm3/h

Filling flow 7m3/h

Connection means: DN80 (material pipe) /3″ flange joint