Loading Port:Guangzhou

Payment Terms:TT OR LC

Min Order Qty:1 set

Supply Capability:0.2 set/month

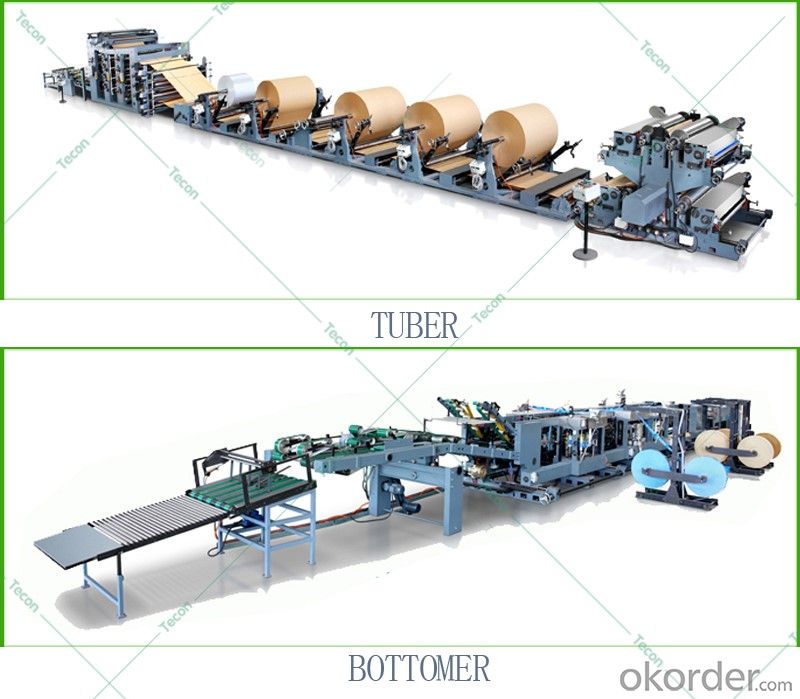

Our paper bag production line consists of paper tube forming machine(Tuber) and bottom pasting machine(Bottomer). The products-Valve bags are used for a vast number of applications, primarily in the building materials and food industries, to filling goods such as:cement,chemical material, feeds, fertilizers,tea,rice etc.

Our Advantage:

1.Specialize in design and manufacture valve paper bag machine for 30 years;

2.CE Certified;

3.Our tuber machine and bottomer machine have gained over 50 utility model patents;

4.Longer service life with NSK bearings,SIEMENS control system and high quality gearings.

5.Cost effective compare to W&H,Germany and Newlong,Japan.

Valve paper Bags:

Different models can produce different kinds of bags,like standard cement bags,chemical/cement bags with bottom strengthen sheet,tea bag with PP Liner to enhanced moisture protection.

Bags can be made of 2~4 layers kraft paper or paper with one layer of PE/PP film.2~4 colors printing available in Tuber line.

The bags opening or valve in one corner through which the sack is filled. The valve is made with an inner flap which functions as a self-closing check valve after filling. It is available with a plain valve or with an extended inner sleeve of paper or film.

Machine Technical Parameters:

| Model | ZT9802S |

| speed | 120 tubes/min |

| Tube Width | 380~620mm |

| Tube length | 400-1400mm |

| Specification gear | 51~80 teeth(M=4) |

| Type of cutting | Step cut&Flat cut |

| Number of ply | 2~4paper+ 1 PP/PE |

| Diameter of print roller | Ø196~ø312 mm |

| Printing width | 1300 mm(MAX) |

| Paper reel diameter | Max. 1, 300 mm |

| Paper reel width | 860--1260mm |

| Main drive motor | 47KW |

| Servo system | YES |

| Machine size | 35.32.42.7(M) |

| Machine weight | N 32(T) |

HD4916BD Bottomer Machine

| Model | HD4916BD |

| Speed | MAX 100/140 bags/minute |

| Tube Width | 380~600 mm |

| Bottom Width | 80~160 mm |

| Valve Sheet Length Width | (100-300)(120-240)adjustable |

| Bag Length | 520~880 mm |

| Bottom Center Distance | 420~780 mm |

| Number of ply | 2~4paper+1 PP/PE |

| Strength sheet unit | YES |

| Strength sheet length*width | (300~600)(80~160) |

| Main Drive Motor | 40KW |

| Machine size | 23/281.81.8(M) |

| Machine weight | N34(T) |

Product show:

After-sale service

1.Provide training during and after the commissioning at the buyer site.

2.One year warranty period from the acceptance at the buyer site.

3.Provide life long technical services and effective solutions.