Loading Port:China main port

Payment Terms:TT OR LC

Min Order Qty:10 SET

Supply Capability:10000 SET/month

Introduction

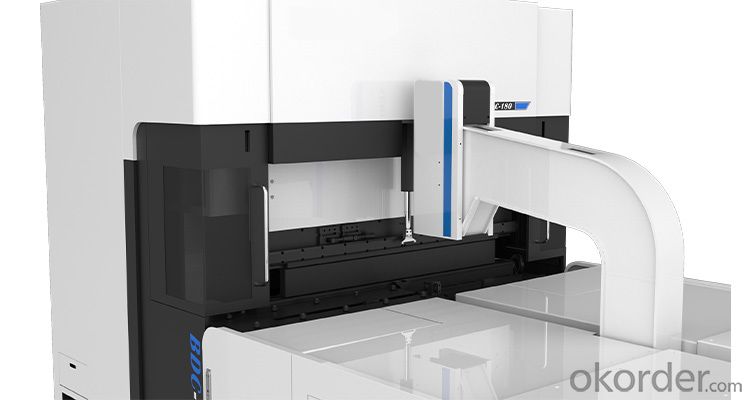

The servo control metal bending machine is an equipment for processing thin plates. Its structure mainly includes a tool holder, worktable, a clamping feeding device and a CNC operating table. The worktable is composed of a base and a clamping piece feeding structure. The workpiece is positioned and clamped on the worktable and delivered to the processing position through the feeding mechanism, and the bending tool is driven by the tool holder to process the workpiece.

The machine body processing by high precision temperature control tempering furnace to completely release the internal stress of welding, ensure it will not easy to deform and the stability of the equipment. The full servo control system can ensure more stable feeding. The bending tool can complete the shape of non-right angle, right angle, circular arc, pressing dead edge, etc

Parameter

Model | BDC-180 |

Bending Length | 1800mm/70.86inches |

Bending Maximum Thickness | 3mm |

Maximum Bending Height | 170mm/6.69inches |

Minimum Bending Height | 6mm/0.23inches |

Minimum Molding Size of Four Sides | 260mm*260mm |

Minimum Size of Unilateral Molding | 160mm |

Minimum Arc Radius | 1.2mm |

Minimum Continuous Bending Speed | 0.2S |

Bending Angle | 0-180 |

Maximum Feeding Speed | 120m/min |

Outline size(mm) | 5000*2600*2900 |

Total Power | 75KW |

Workbench Structure | Mainly with brushes |

Quantity of Axis | 13-axis concurrent linkage |

Higher Bending Accuracy

Fully Automatic and More Intelligent

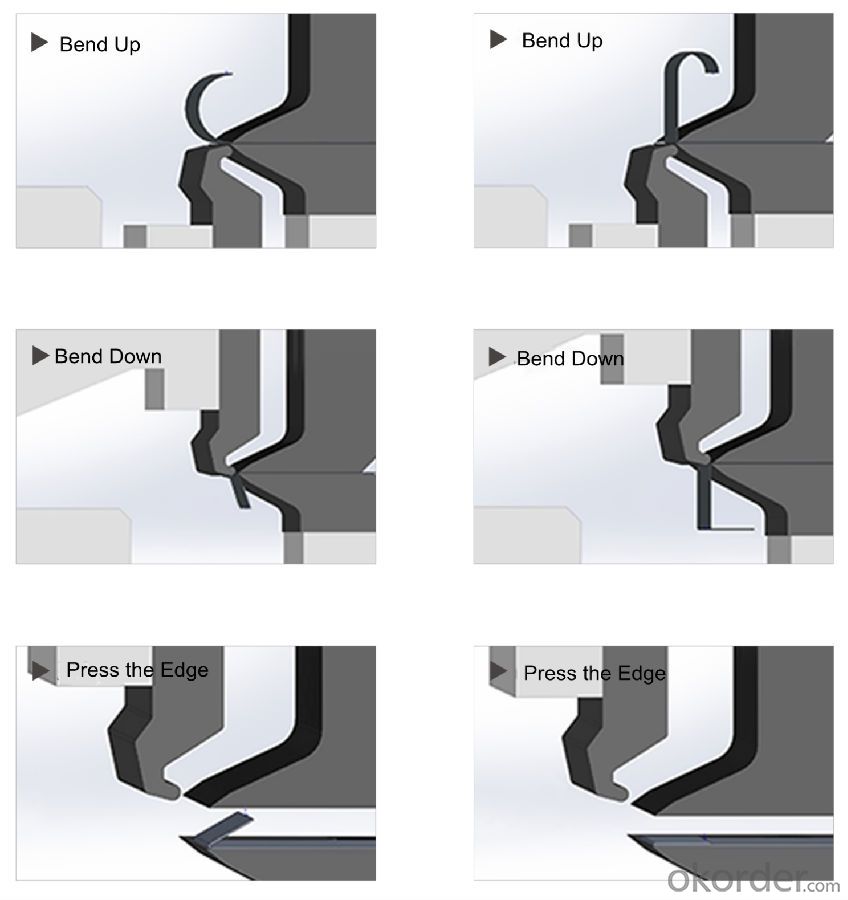

Various Bending Shapes

The bending tool can complete the shape of non-right angle, right angle, circular arc, pressing dead edge, etc.

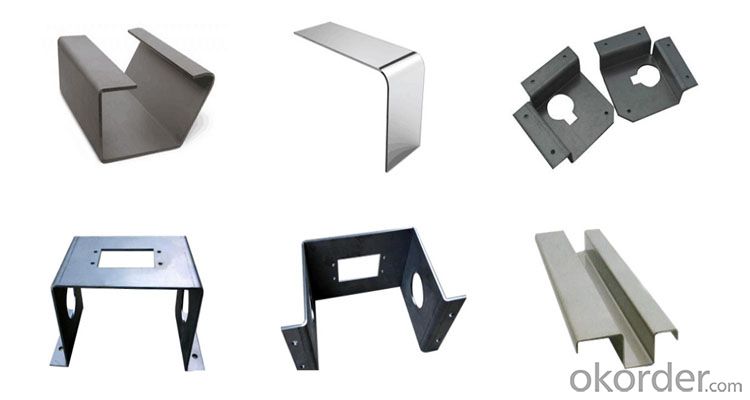

Samples Show

This bending machine is a high-tech product developed and produced for the sheet metal industry to improve productivity, reduce the labor intensity of operators, improve product quality, widely used in refrigeration, medical treatment, building materials, kitchen utensils, environmental protection, wind turbines and other industries.

Steel | Maximum Thickness |

Carbon steel(mm) | 1.5 |

Stainless steel(mm) | 1.2 |

Aluminum (mm) | 2.5 |