Loading Port:China main port

Payment Terms:TT OR LC

Min Order Qty:100 unit

Supply Capability:10000 unit/month

Introduction

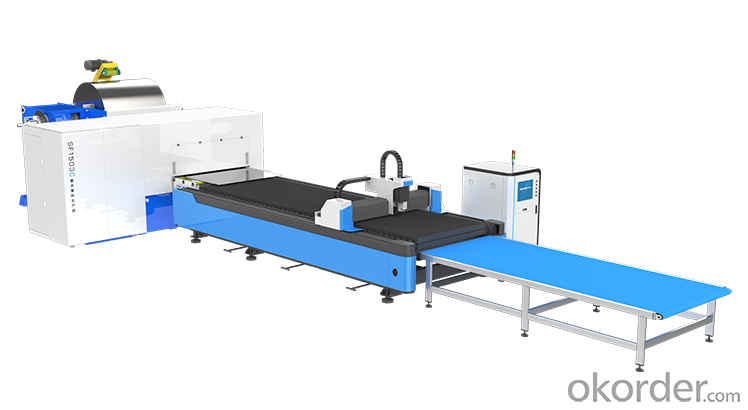

Fiber laser blanking system combines a fiber laser cutting machine with an automatic metal coil feeding system resulting in an efficient coil fed laser cutting solution .

Laser blanking reduces power consumption compared to its alternatives, such as press lines and results more efficient and flexible.

The automatic design of the whole process, which is from loading-uncoiling-leveling-cutting saves labor, realizes the net cutting of coil materials, and improves the utilization of sheet materials.

Parameters

Model | Coil-fed Laser Blanking System |

Applicable materials | Cold rolled coil, galvanized coil, stainless steel coil, aluminum coil |

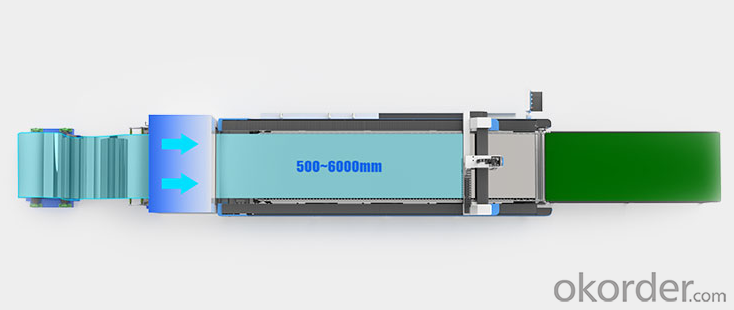

Working area(mm) | 3000*1500/4000*2000/6000*1500(mm) |

Laser power | 1kw/1.5kw/2kw/3kw/4kw |

Material thickness | 0.5-2mm |

Material width | 600-1500mm |

Maximum coil weight | 10T |

Maximum outer diameter of material | Φ1500mm |

Material inner diameter | Φ508/Φ610mm |

Feeding accuracy | ±0.5mm (calculated by 1000mm) |

CNC system | Feeding speed |

Details:

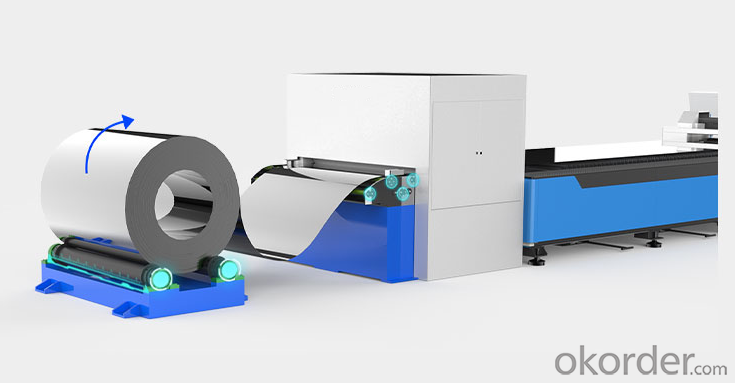

The load-bearing capacity of the single-support uncoiler is 10 T, and the feeding speed of uncoiler is 0-10m /min (stepless speed regulation).

After the coil is uncoiled, the plate is leveled by the leveling machine, and the stress of the plate during the leveling process is eliminated, so that the plate is smoother and a better cutting experience is obtained.

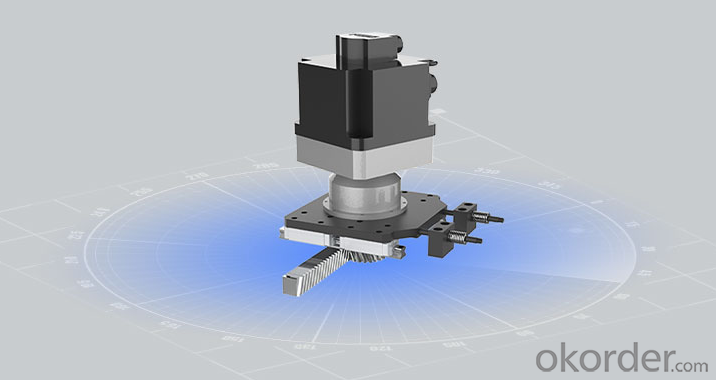

The special screw nut is used to drive the rectifying roller to install the slide block, so as to realize the positive orientation of the plate , no need laser edging and save the cutting time of the plate.

Ultra-precision transmission system is adopted, high transmission accuracy.