Loading Port:Shanghai

Payment Terms:TT OR LC

Min Order Qty:1 set

Supply Capability:200 set/month

1. Description of the Automatic Auger Filling Machine

This Machine is a complete, economical solution to your filling production line requirements.can measuring and filling powder and granular. It consists of the Filling Head, an independent motorized chain conveyor mounted on a sturdy, stable frame base, and all necessary accessories to reliably move and position containers for filling, dispense the required amount of product, then quickly move the filled containers away to other equipment in your line (e.g., cappers, labelers, etc.).it fits more to the fluidic or low-fluidity materials, like milk powder, albumen powder, pharmaceuticals, condiment, solid drink, white sugar, dextrose, coffee, agriculture pesticide, granular additive, and so on.

2. Features

- Lathing auger screw to guarantee the precise filling accuracy

- PLC control and touch screen display

- Servo motor drives screw to guarantee stable performance

- Quick disconnecting hopper could be washed easily without tools

- Can be setting to semi-auto filling by pedal switch or auto filling

- Full stainless steel 304 material

- weight feedback and proportion track to materials, which overcomes difficulties of filling weight changes due to materials’ density change.

- Save 20 sets of formula inside the machine for later use

- Replacing the auger parts, different products ranging from fine powder to granule and different weight can be packed

- Multi language interface

3. Technical parameters

First type-Liner type

| Model | TP-PF-A21 | TP-PF-A22 |

| Control system | PLC & Touch Screen | PLC & Touch Screen |

| Hopper | Quick disconnecting hopper 25L | Quick disconnecting hopper 50L |

| Packing Weight | 10 - 5000g | 10 - 5000g |

| Dosing mode | Directly dosing by auger | Directly dosing by auger |

| Paching accuracy | ≤500g, ≤±1%; >500g,≤±0.5% | ≤500g, ≤±1%; >500g,≤±0.5% |

| Filling speed | 15 - 40 times per minute | 15 - 50 times per minute |

| Air supply | 6 kg/cm² 0.05m³/minute | 6 kg/cm² 0.05m³/minute |

| Power supply | 3P AC208-415V 50/60Hz | 3P AC208-415V 50/60Hz |

| Total power | 1.6 KW | 1.6 KW |

| Total weight | 300 kg | 300kg |

| Overall Dimensions | 2000*970*2030mm | 2000*970*2300mm |

Second type- Rotary type

| Model | TP-PF-A301 | TP-PF-A302 |

| Hopper volume | 25L | 50L |

| Container size | φ20-100mm; H15-150mm | φ30-160mm; H50-260mm |

| Control system | PLC & Touch screen | PLC & Touch screen |

| Packing weight | 1 - 500g | 10 - 5000g |

| Packing accuracy | ≤100g, ≤±2%; 100-500g,≤±1% | ≤500g, ≤±1%; >500g,≤±0.5% |

| Filling speed | 20-50 bottles per minute | 20-40 bottles per minute |

| Power supply | 3P AC208-415V 50/60Hz | 3P AC208-415V 50/60Hz |

| Total power | 1.2 KW | 2.3KW |

| Air supply | 6kg/cm² 0.05m³/minute | 6kg/cm² 0.05m³/minute |

| Total weight | 160kg | 260kg |

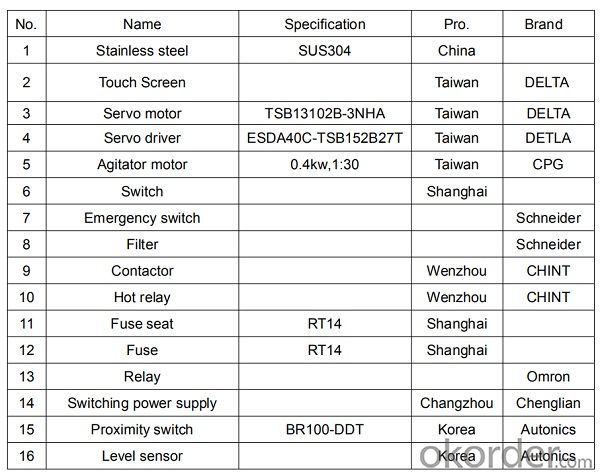

4. Configuration list

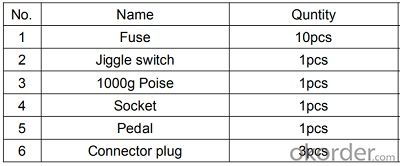

Accessories

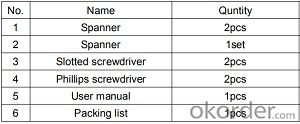

Accessories tools

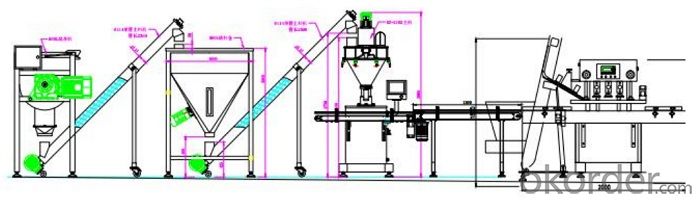

5. Image of fonction

6. Remark

- Delivery Period: 25 days after receipt of down payment

- Payment Terms: 30%T/T as deposit + 70%T/T balance payment before delivery.

- Guarantee Period: 12 months

- Package: seaworthy plywood carton