Loading Port:Shanghai

Payment Terms:TT OR LC

Min Order Qty:1 m²

Supply Capability:10000000 m²/month

climbing formwork

1.Material: ASTM45#,Q235 steel

2.ISO 9001:2008

1. Specifications:

| Commodity | climbing formwork |

| Specifications | 45# steel or Q235 |

| Colour | primary |

| Length | according to customers' requirement |

| Usage | building construction |

| Technical processing | hot rolled |

| Surface | F Type Flattening |

| Packing | 200pcs or 400pcs in a pallet |

| in a container | |

| MOQ | 20 metric ton |

The concrete form panels are kind of systemized formwork, easy to install and to dismantle for the reinforced concrete construction in any type. The structure of the panels is conveniently designed for various functions, enabling the panels to be reused repeatedly, helping save the costs on materials and reduce the times for work by simplifying and accelerating the process. Consequently it can cut down on the labor costs and expenses. Basic and standard products as well as various products for different types and sizes of constructions are available from manufacturing. Recycling the panel after its life-span can help reduce costs, because we can remove plywood, adjust the frame and the angle, get rid of the impurities, carry out coloring and finally attach the new plywood. The recycled forms still perform as good as the new ones, with substantially reduced costs. Other types of recycled panel are those who combine the recycled frames and the used plywood which is still in good condition.

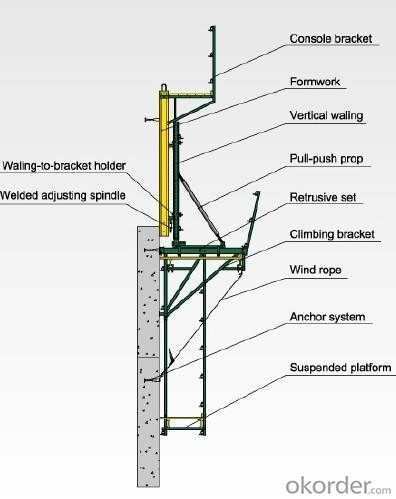

1. Structure of Cantilever Formwork Description

Cantilever Formwork is mainly used in the concrete pouring of pier, high buildings, and so on. The concrete lateral pressure is entirely supported by anchor system and the wall-through tie-rods, additional reinforcement is not needed. The construction is easy, rapid and economical. A single pouring height is high and the finished concrete surface is perfect. Cantilever formwork has several types, the structure is similar, and has its own different characteristic. Can use them according to actual demand.

Main cantilever Formwork:PJ200 & PJ240,CB-240 etc.

2. Main Features of Cantilever Formwork

-easy to assemble

-simple structure.

-easy, rapid and economical.

3. Cantilever Formwork Images

4. Cantilever Formwork Specifications

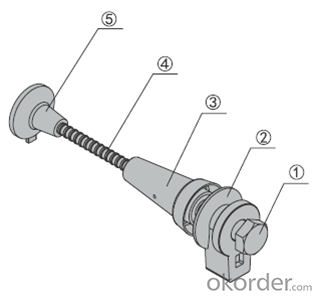

Anchor system

Anchor system is the most important supporting part. The system is made of five parts shown below. There into, tensile bolt, anchor shoe and bowl-climbing cone can be taken out for reusing after the concrete pouring.

① Tensile bolt M30/L= 110

② Anchor shoe

③ Bowl-climbing cone M30/D15

④ High-strength rod D15

5.FAQ of Cantilever Formwork

1) What can we do for you?

.We can ensure the quality of the Cantilever Formwork and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in this kind of formwork, please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issueS.

3) What about of our after-sale services?

. Response will be carried out in 24hours after receiving any complain or request.

. Any formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: wood package and adhesive tape

.Shipping: by sea

Shipping time: Normally small orders, it just1week business days to arrive your hand; When comes to the customs declaration, it may need 2weeks.