Loading Port:Shanghai

Payment Terms:TT OR LC

Min Order Qty:50 m²

Supply Capability:1000 m²/month

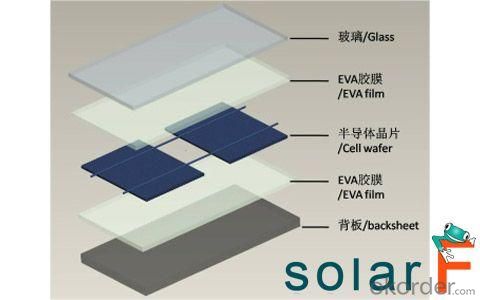

1. Structure of Anti-PID Grade EVA for Solar Module Type S201MR

EVA is an adhesive film with thermoset and viscosity, it is more often used in the solar module and other optic products since it does better in the performance of adhesive force, durablity and optical property. EVA is short for Ethylene Vinyl Acetate, which is placed between the laminated glass and two layers of EVA just press from both sides of the solar cell. This Anti-PID EVA for Solar Module type S201MR has excellent performance in both 65℃85% and 85℃85% 1000V PID test. In 65℃85%, S201MR can stand 192 hours aging.

2. Main Features of Anti-PID Grade EVA for Solar Module Type S201MR

Excellent light transmittance and transparency

Good manoeuvrability during lamination process with low breakage rate

Excellent adhesion to glass, metal and plastics PET, TPT, maintaining long term adhesion

EVA is the high-quality PID-free materials to prevent damages for PV modules.

3. Anti-PID Grade EVA for Solar Module Type S201MR Images

4. Anti-PID Grade EVA for Solar Module Type S201MR Specification

| Item | S201MR |

| Power before test W | 240.57 |

| Power after 96 hrs W | 240.13 |

| Power lose after 96 hrs % | -0.18% |

| Power after 192 hrs W | 229.45 |

| Power lose after 192 hrs % | -4.6% |

After PID test, 85℃85% 1000V, S201MR has better performance comparing to competitor. Except EVA, all other parts are the same in all tested modules.

S201MR before test

S201MR after test

S Co. PID-EVA before test

S Co. PID-EVA after test

5. FAQ

(1) Can the customer order for the specified EVA?

Length of films is 100 meter or customers is able to specify how long the film they need. Each roll has each paper core, PE sealing bag and paper box. Once original package is opened, films should be consumed within a short time. So the customer should take all the factors under consideration to make full use of the EVA.

(2) What is the laminating technique of the this anti-PID EVA ?

Recommended curing condition is 145゜C, vacuuming 3 minutes and keeping 12 minutes, Customers can adjust curing condition according to equipment, and crosslink requirement.

(3) How to offer appropriate storage for the EVA?

The EVA has to be stored in original unopened containers in a cool and dry place/warehouse, avoid sun light directly during the transportation, the temperature should be maintained under 30゜C, no rainy as well.