Loading Port:Shanghai

Payment Terms:TT or LC

Min Order Qty:5 m.t.

Supply Capability:10000 m.t./month

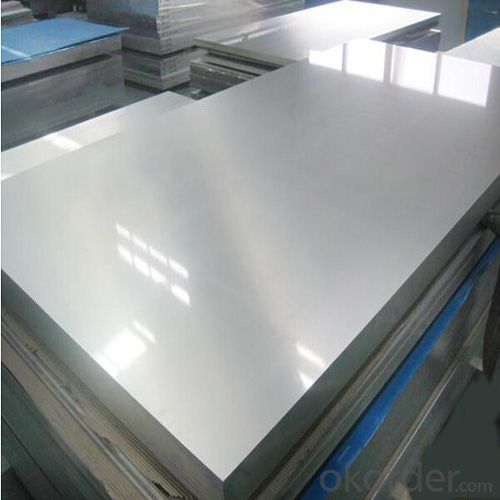

1.Structure of Aluminum Thick Plate for Shoe Molds Description:

Our company can supply aluminium thick plates 6061. The thickness is 2mm-250mm, the common surface is polished with clear PVC film. The temper is T6, T651, F, H ect.

Good Corrosion Resistance

Good Machinability

High Quality

Competitive Price

4. Aluminum Thick Plate for Shoe Molds Specification:

| Specification | Name: 6000 series Aluminum Plate | |||||||||||

| Alloy: 6061, 6082 etc. | ||||||||||||

| Temper: O, H112, T6, T651 etc. | ||||||||||||

| Thickness: 6-200mm | ||||||||||||

| Width: Up to 1500mm | ||||||||||||

| Surface treatment: mill finished, Print marks | ||||||||||||

| Feature | Machinability: In the harder T 4 and T6 tempers it is good. It is notably less easy to machine in the annealed temper. | |||||||||||

| Forming: Easily cold worked and formed in the annealed condition. Stamping, bending, spinning, deep drawing are all readily accomplished using standard methods. | ||||||||||||

| Welding: It has very good welding characteristics and may be welded by all of the common welding techniques. | ||||||||||||

| Heat Treatment: Solution heat treat at 990 F for adequate time to allow for thorough heating and then water quench. Precipitation hardening is done at 320 F for 18 hours and air cool, followed by 350 F for 8 hours and air cooling. | ||||||||||||

| Forging: It is capable of being hot forged at temperatures in the range of 900 F to 750 F. | ||||||||||||

| Hot Working: Hot working may be done in the temperature range of 700 F to 500 F. | ||||||||||||

| Cold Working: Cold working in the O temper condition is readily performed. The alloy is notably less easy to cold form in the T 4 and T 6 tempers. | ||||||||||||

| Annealing: Annealing should be done at 775 F for 2 to 3 hours followed by controlled cooling at 50 f per hour down to 500 F, then air cool. | ||||||||||||

| Aging: The aging precipitation heat treatment is done at 350 F for 8 hours followed by air cooling. This produces the T6 temper. | ||||||||||||

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.