Loading Port:Yantai

Payment Terms:TT OR LC

Min Order Qty:7 m.t.

Supply Capability:200 m.t./month

1.Structure of PVDF Aluminum Coil for ACP Description:

PVDF coated aluminum coils are specially processed through the technics of roller coating and baking with precise paints from BECKER INDUSTRIAL COATINGS in Sweden and THE VALSPAR CORPORATION in USA. The main material of PVDF is polyvinylidene fluoride resin; the utmost negative characteristic of the Fl atom can form a very strength high powerful Fl-C bond. Moreover, with the special symmetry molecule structure, the products are of strong weather resistance performance, anti-ultraviolet performance, super long durability and anti-corrosion performance, which can maintain very bright and glossy color even serving for 20 years in outdoor environment. Attributing to the abrasion resistance and impact resistance and flexibility, our products are of excellent mechanical processing performance.

PVDF coated aluminum coils are the highest priority of choice to high class aluminum composite panels, and its composite products are widely used in airport, exhibition center, administration center, star hotel and other symbol building.

2.Main Features of the Aluminum PVDF Coated Coil:

• Light Weight

• High Flatness

• Protecting Environment

• Good Weathering

• Colorful

• Recycling

• Saving Energy

• Rustproof

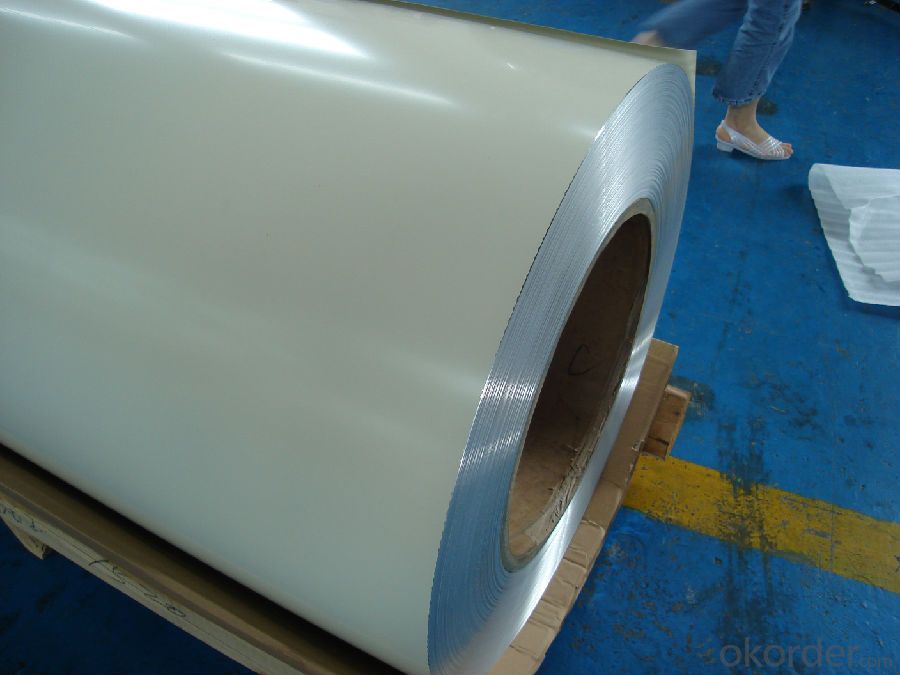

3.Aluminum PVDF Coated Coil Images:

4.Aluminum PVDF Coated Coil Specification:

Aluminum Thickness | Coating Thickness | MEK | T Bend | Impact | Adhesion | Pencil Hardness | Boiling Water Proof |

0.3-1.5mm | ≥25μm | ≥100 Times | ≤2T | 50kg•cm No falling.No crack | 0 Grade | ≥1H | no change within 2 hours |

0.15-0.28mm | ≥25μm | ≥100 Times | ≤2T | 20kg•cm No falling.No crack | 0 Grade | ≥1H | no change within 2 hours |

PVDF Aluminum Coil for ACP

Features of PVDF Aluminum Coil:

1. Adopting precision rolling coating technology, our PE coated coil can ensure excellent adhesive without coating omission.

2. For the PVDF coated aluminum sheet we produced, there are various colors for your choice.

3. Using infrared heating technology to protect environment from pollution.

4. Our coated aluminum coil has four-roller coating line, uniform coating thickness and good features.

Raw Material of the PVDF Coated Aluminum Coil:

1. Aluminum Coil: high strength aluminum with alloy of AA1100 (aluminum alloy is available with AA3003, AA3005, AA5005 according to customer)

2. Surface Paint: PE, PVDF and special paints.

Specification of the PVDF Coated Aluminum Coil:

Width: 20mm~1590mm

Thickness: 0.06mm~1.0mm

External Diameter: ≤ 1500mm

Internal Diameter: 405mm, 505mm, 150mm, 75mm

Coil weight: ≤ 4000kg

5.FAQ

1. Color of Card

Our PVDF coated aluminum coil is made of fluorine carbon resin, pigment, ester solvent after high temperature roasting and baking. The paint of this PVDF coated aluminum coils are solidified to dry film with super weather resistance. PVDF coating also can be classified as traditional PVDF and nanometer PVDF coating.

A. Traditional PVDF Coating, with KYNAR500 PVDF and two or three times for coating and baking, has good properties of anti-acid, anti-alkali and is durable in atrocious weather and environment, keeping 15 years no unwonted fading. In view of these facts, we recommend this PVDF coated aluminum coils are applied for external wall cladding.

B. Nanometer PVDF Coating, which different with traditional PVDF, is the clear coating. It contains nanometer element, which can protect panel from pollution, because nanometer has self-cleaning effect, it is easy to get rid of dust and pollution by raining or water.

2. Color Match

For custom' color requests, we can deal as following:

1. Supply a physical sample of custom color. A color sample on metal is preferred. If other, it is also acceptable. But the color matching rate may be not good as color on metal.

2. New color sample is usually offered by our paint supplier in 5-7 days, special color should be in 7-10 days.

3. Upon receipt of color sample, please approve in writing as soon as possible. Once you approved, we will arrange purchasing and production.

Note: Color difference maybe occurred in different production batch, so it is suggested all panels are placed in one order for same project. And keep same direction as arrow on protective film when installing to avoid any color difference by vision.

3.How long can we receive the product after purchase?

15-20days for general specification and 35days for special specification after receiving the deposit.