Loading Port:Tianjin

Payment Terms:TT or LC

Min Order Qty:200 kg

Supply Capability:20000 kg/month

Among the wide range of building materials supplied by CNBM, custom aluminum (or 'aluminium' in British English) extrusion profiles stand out, designed specifically for construction-related applications. These profiles are meticulously manufactured and undergo a high-quality anodization process to ensure both durability and aesthetic appeal. If you have a design, simply send it to us, and we will bring your vision to life in real products.

Aluminum alloy parts and profiles are produced either through die-casting or using a precision-designed extrusion die. The most commonly used aluminum alloy in the building industry is 6063-T5.

Aluminum round bars serve as the primary raw material for aluminum profile extrusion.

We maintain a stock of extended aluminum bars in preparation for profile extrusion.

Our aluminum extrusion workshop.

;Our aluminum extrusion workshop.

The warehouse where extrusion aluminum profiles are stored.

Similar to other metal fabrication processes, aluminum profiles may also require the transformation of semi-finished materials into final products through cutting, punching, drilling, or CNC machining. Specialized aluminum fabrication work is conducted in our dedicated fabrication shops (fab shops). Common methods include cutting, drawing, folding, forging, machining, punching, shearing, stamping, and welding to reshape or create new products. Our fab shops also provide finishing services such as deburring, polishing, coating, and painting to ensure the highest quality of the final product.

Director Hailong addressing and resolving machining issues.

Our advanced aluminum fabrication shop.

Our advanced aluminum fabrication shop.

Specially designed 90-degree angle turrets within the mold punch holes in the aluminum profile.

An anodized finish is a clear or colored coating chemically applied to the surface of aluminum. This process not only thickens the natural oxide layer on aluminum parts but also protects them from corrosion. Additionally, anodizing alters the crystal structure near the surface of the aluminum alloy, allowing us to impart vibrant colors to the metal. Depending on the size and intended use of the aluminum component, anodizing can be categorized into two methods: 'long-profile anodizing' and 'small-widget anodizing.'

We anodize long profiles by stacking them in a large metal basket.

The metal basket is submerged in a sizable oxidation pond containing chemicals.

Aluminum profiles are typically immersed in the oxidation pond for approximately 20 to 40 minutes.

Anodizing small aluminum parts to a vibrant red hue.

Anodizing small aluminum parts to achieve a vibrant blue color.

Anodizing small aluminum parts to a shining gold color.

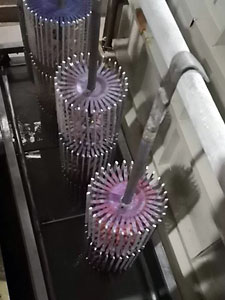

Grippers or holders used in the anodizing process for small and thin aluminum flashings.

A die-cast aluminum item anodized in a clear aluminum color.

A die-cast aluminum item with a white electrostatic spray coating.

An aluminum profile bar designed for use in camping tents.

CNC milled aluminium extrusion heat sink radiator.

CNC milled aluminium extrusion heat sink radiators.

CNC milled aluminium extrusion heat sink radiators.

Frosted-anodized aluminum flashing designed for roofing system.

T-shaped aluminum industrial rail system with fixing and drainage holes.

T-shaped aluminum industrial rail system with fixing and drainage holes.

Cross-section view of aluminum profiles in both L and T shapes.

A wooden case for packaging bundled aluminum profiles wrapped with protective film.

Our inventory of extruded aluminum profiles with various section shapes.

Aluminum profile samples with different anodized colors: brown, gold, champagne, and black.

An aluminum part anodized to achieve a gold color.

Aluminum alloy tubes anodized and dyed in violet and blue colors.

Last Updated: 2024-09-24