Loading Port:Guangzhou

Payment Terms:TT OR LC

Min Order Qty:1 set

Supply Capability:10 set/month

Die Cleaning Machine

1. The machine discharge the waste materials out of the extrusion die by the action of hydraulic pressure, reduce erode time and improve the usage rates of material.

2.The size can be designed and customized according to customers' requirements.

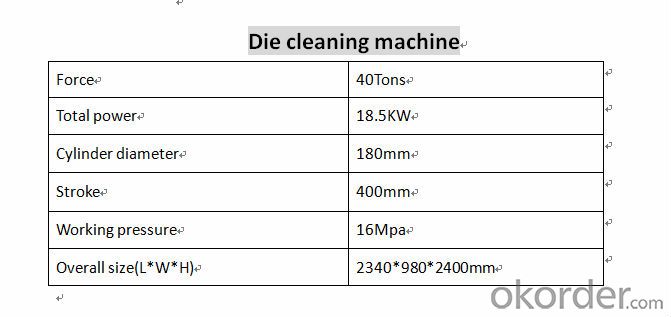

Technical parameters:

Packaging & Delivery

Packaging Details: Container

Delivery Detail: Within 40 days after received payment

Other Popular Products:

Aluminum Profile Extrusion Handling Table

Aluminum profile handling table is designed for the primary treatment after profile extruded, including the profiles' cooling, conveying, pulling, straightening, gauging and cutting. This equipment mostly for 500T-1800T aluminum extrusion press, adopt heat resistant felt belt and felt roller to convey, it can effectively avoid the profiles' secondary scraped and distorted, improve the product pass rate.

Aluminum Profile Packing Machine

The machine is designed for aluminum production packing, which is of good looking, easy operation, and low noise, good packing effect features.

Aluminum Billet Cutting Machine

The equipment can put a lot of billets on the storage table and continuously cut billets. It is mostly used in aluminium founding factory

Aluminum Profile Correction Machine

Aluminum Profile Film Sticking Machine

It has following feature: high taping speed, rigid taping effect and easy operation.The finished goods will has more competence after they are taped by this machine.

Aluminum Profile Finish Saw

The machine usually is working together with saw gauge table, it can be adjusted according to the length of extruded profiles;

Die Cleaning Machine

The machine discharge the waste materials out of the extrusion die by the action of hydraulic pressure, reduce erode time and improve the usage rates of material.

Aluminum Auto Stacker

1. The Auto stacker equip after the finish saw cutting, to storage the profile automatic;

2. Transfer many pieces of profile and the productive efficiency is high;

3. The entire productive line is controlled by computer so it is highly automatic