Loading Port:China main port

Payment Terms:TT OR LC

Min Order Qty:1000 m²

Supply Capability:50000 m²/month

Specifications:

Designed and engineered to perform in multiple commercial environments under multiple stresses, cmax Metal Ceiling systems allow cutting-edge technologies to be applied to the most modern or traditional designs. Every component is designed and fabricated to exacting specifications and the highest manufacturing standards.

Ceiling Type | Size(mm) | Height(mm) | Thickness(mm) | Edge Type |

Clip In Ceiling | 300*300 | 18/20 | 0.45~0.56 | Beveled Edge/Square Edge |

600*600 | 20/24/28 | 0.45~0.7 | Beveled Edge/Square Edge | |

800*800 | 20/24/28 | 1.0 | Beveled Edge/Square Edge | |

300*1200 | 20/24/28 | 0.75~0.9 | Beveled Edge/Square Edge | |

600*1200 | 20/24/28 | 0.75~1.1 | Beveled Edge/Square Edge | |

Lay In Ceiling | 275*275 (295*295) | 8 | 0.60~0.70 | Square Edge |

575*575 (595*595) | 8/12/18 | 0.60~0.70 | Beveled Edge/Square Edge | |

585*585 (595*595) | 10 | 0.60~0.70 | Square Edge | |

585*585(605*605) | 10 | 0.60~0.70 | Square Edge | |

595*1195*575*1175 | 8 | 0.60~0.70 | Square Edge | |

603*1210*585*1195 | 8 | 0.60~0.70 | Square Edge | |

Ceiling Type | Open size(mm) | Width & Height(mm) | Thickness(mm) | Length(mm) |

Open Cell Ceiling | 50*50 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 2000 |

75*75 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 1950 | |

100*100 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 2000 | |

125*125 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 2000 | |

150*150 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 1950 | |

200*200 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 2000 | |

Ceiling Type | Width(mm) | Length(mm) | Thickness(mm) | Edge Type |

C-strip | C100/C150/C200/C300 | 1000~6000 | 0.45~0.85 | Beveled Edge/Square Edge |

S-strip | C300 | 1000~6000 | 0.45~0.85 | Beveled Edge/Square Edge |

H-strip | C150/C200/C300 | 1000~6000 | 0.45~0.85 | Beveled Edge/Square Edge |

G-strip | C100 | 1000~6000 | 0.45~0.85 | Square Edge |

Detailed product description:

1) Item: W-35, 38 main channal, L angle, Connor Bead, DC-60, U-60, 50 Stud & track, 75 Stud and track, 100 Stud and track, ect.

2) thickness: 0.4-1.0mm

3) Length: 3000mm or dependes on customer's request

4) Zinc coating: 50-220g/m2 (depends on the customer's request)

5) Size as fellow form: (Width*Height*Thickness)

Product apply in: Mid East , Rusia, Europ, South America, Africa

Certificate for products:CE,stand :EN13964; ISO9001-2000

Instructions:

(1) Lightweight and high strength: 3-4 kg/m2 (1/10 of half brick wall), with yield strength 400mpa.

(2) Environment-friendly : galvanized steel-no radiation, have no harm to our health and not pollute the environment.

(3) Products with fillisters : Setting some fillisters in both sides of the keels in a selective way, in order to strength the keels' vertical points and intensity.

(4) The metal stud with hole : one of our product is the special hole on C-stud every 600mm, which is easy for workers to install the electric lines and water tubes.

(5) Various sizes of metal track and metal stud : we are able to manufacture German,

(6) Factory direct sale price : We have our own factory to produce raw materials----galvanized(zinc coated) steel, as well as the product line, so we can provide you a lowest price.

Installation and Accessories

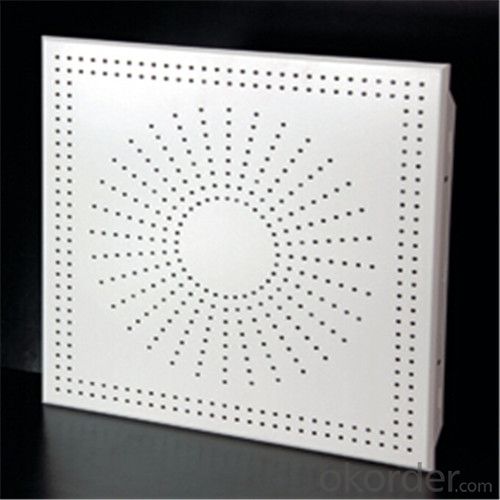

Clip-in Concealed Metal Panel Ceiling

*Clip-In Panels are constructed of recycled aluminum

*Springs and clips are constructed of high performance steel

*Clip-In Panels integrate into and conceal 15/16” face HD/ID suspension grid

*Clip-In Panels for use in interior application

*Square edge design

*Standard sizes of 24” x 24”, 24” x 48” or custom size

*Clip-In Panels available in solid or perforated designs

*Clip-in placement allows for downward accessibility without special tools

*Easily incorporates air, fire, audio and other services

*Panels contain no organic compounds that support mold or microbial growth

*Factory applied, no-VOC powder coated paints and laminated finishes

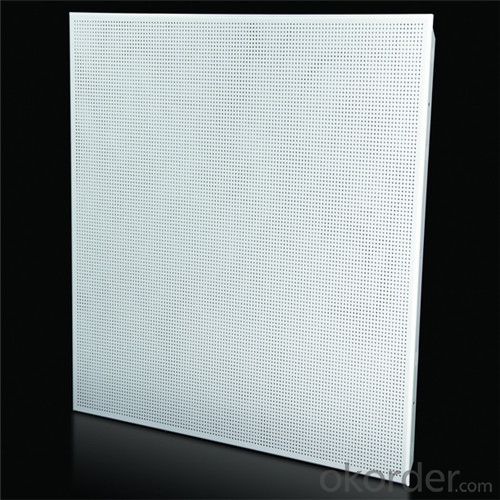

The Lay in (I) system is easy to match grid system. The panels are right angle by 8mm chamfer. It's 100% upward accessible and installed on either silhouette grids or other 9/16" (15mm) exposed tee grids, forming unique overall effect. The silhouette grids also can offset manufacturing tolerance and installation tolerance. Also, it can be combined with mineral fiber panels to present a various installation effect.

FAQ

1.Sample: small sample can be offered by free

2.OEM: OEM is accepted

3.MOQ: small order is ok

4.Test: any third party is accepted to test

5.Factory: Can visit factory any time

6.Delivery Time: small order is within 7days or according to your order