Loading Port:Shanghai

Payment Terms:TT OR LC

Min Order Qty:-

Supply Capability:1000000meters m/month

SAFETY FEATURES

Anti-creeping feature of pure Al is weak. During long-term operation, the gaps, which will cause increasing of contact resistance between conductors, will appear due to thermal-cooling cycle. The contact point is easy to generate heat and it is not safety for long-term operation. The problems could be solved effectively through high conductivity alloy conductor.

1, Trend of creepage is largely minimized account for heat and press of material due to special conductor formula and heat treatment technology. Even overheat and overloading happen on cable within long time, it could keep the stability of connection. This has been proved to effective through long-term operation in large amount of labs and in Europe and America Countries.

2, Special arched interlocking armoring structure of interlocking armored cable has excellent feature of dispersing the side pressure. Adopting the 5000 series high-strength Al-alloy metal tape, which is non-magnetic material and does not form eddy current loss. The material has better performances as heat dissipation, anti-corrosion, strong and toughness, flexibility, smooth armoring inside, without damage to insulation, better shield and flame-retardant.

3, Al-loy cable is equipped with various connection and services as copper and Al accessories. It eliminates the electrical and chemical corrosion among connections of different metals. Oxidation of metal surface causes large resistance. It simplifies installation and safe to be used.

Al-alloy cable is light and replaces 50% of equivalent cable. Length of alloy cable is 2 times of copper cable with the same quality. For spanning buildings, it can save 15% steel structure. Smaller loads could improve the safety of the building.

Conductivity Feature

Compare the cable with same specification, conductivity of alloy conductor manufactured by Sinyu company is 62.5% of normal international annealed copper standard (IACS). However, the actual weight of Al is one third of copper with the same volume. According to the calculation, at the premise of meeting requirements of same conductivity, length of alloy cable with the same weight is two times of copper cable. Therefore, the weight of alloy cable is half of copper cable under the same current rating. When the cross section of alloy cable is 1.5 times of copper conductor, the electrical performance is nearly the same. Cable weight could be minimized through alloy cable instead of copper cable. It could reduce the installation cost, minimize abrasion of equipment and cable and it is easy to be installed.

Anti-creepage Feature

Trend of creepage of metal under heat and pressure is greatly minimized through special alloy formula and heat treatment technology. Stability of Electrical connection by high conductivity alloy conductor is the same as copper conductor.

Thermal Expansion Coefficient

Thermal expansion coefficient is used to calculate the dimension change of material under temp variation. The thermal expansion coefficient of alloy cable is slightly higher than copper. It has more expansion and shrinkage than copper under change of same temperature.

We recommend using Copper-Al transit connector that connects the high-conductivity alloyed conductor. It has passed 1000 times thermal cycling test specified in GB 9327 (IEC 61238) standard. Reliability of electrical connection is proved. And, it completely solves problems of thermal expansion and copper-Al electrical and chemical corrosion at the connecting point of two kinds of metals by Copper-Al transit connector.

Connection Feature

The connection feature is largely improved by alloy composition in alloy conductor. That is the basic reason for being approved as ACM conductor material. Iron element enhances the anti-creepage feature. It can guarantee the stability of connection due to long-time overloads and overheat. When the connector, which is subject to 1000 times thermal cycling in GB 9327 standard, it can guarantee long-term stability and reliability of connection. It is not necessary for fastening connection of high conductivity alloy for the reason that it will damage the connection feature.

Mechanical Features

1, Rebound of high-conductivity alloy cable is 40% less than copper cable.

2, Flexibility of high-conductivity alloy cable is 24 more than copper cable.

3, High-conductivity alloy cable has better bending feature and it is easy to be connected.

4, The thermal expansion coefficient of alloy cable is slightly higher than copper. It has more expansion and shrinkage than copper. Therefore, alloy conductor could not be connected by copper connector.

Anti-corrosion

Anti-corrosion feature of alloy conductor is resulted from thin and tight oxidation layer formed through contact between alloy surface and air. The oxidation layer is resistant to various corrosion. Alloy is expansively applied to cable conductor inside the tray and many industrial components and containers account for resistance to hazard environment. Corrosion is related to connection with various metals under damp environment. Relevant protection measures shall be taken to prevent corrosion. For example, lubricant oil, antioxidant and protection coating can be applied. Insulation or sheath could be applied to buried Al conductor to prevent corrosion. In sulphur environment, such as railway, channel, sewage treatment areas, anti-corrosion feature of alloy is better than copper.

Armoring

5 xxx series Al-alloy is applied

Max. Side pressure:

Alloy cable: 4380N/m*Rm (Rm is bending radius, in m)

Armored copper cable: 3000N/m*Rm

Interlocking armoring

Magnetic material, without eddy current

Heat dissipation

Anti-corrosion

Easy to be installed

Arched armoring, disperse side pressure, smooth armoring inside, without damage to insulation

Flame-retardant

Cable Description

Alloy (R) power cable for 0.6/1kV power distribution

ZA-AC90 (-40)

Replace (WDZA) YJY/YJV/VV

Min. Operation ambient temp: -40°C

Long-term permissible temp of cable conductor: 90°C

Advantages: flame-retardant, class A, LSOH, indoor visible installation, save wireway

ZB-ACWU90 (-40)

Replace (ZR) YJV/22/VV22

Min. Operation ambient temp: -40°C

Long-term permissible temp of cable conductor: 90°C

Water-proof, corrosion resistant, sunshine ageing resistant

Advantages: flame-retardant, class B, buried or damp environment installation, insulating and sheathing material shall be without heavy metal

ZC-TC90 (-40)

Replace (ZR) YJV/VV

Min. Operation ambient temp: -40°C

Long-term permissible temp of cable conductor: 90°C

Sunshine ageing resistant

Advantages: flame-retardant, class C, indoor wireway or outdoor piping installation, insulating and sheathing material shall be without heavy metal

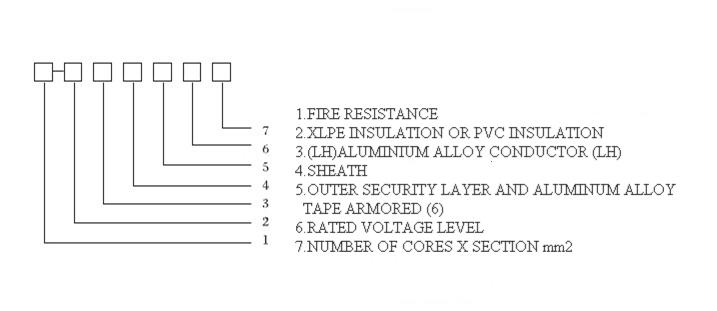

1. Fire-resistant

2.XLPE or PVC insulation

3. (LH) Al-alloy conductor (LH)

4.Sheath

5.Outer coating and Al-alloy tape armoring (6)

6. Voltage grade

7. No. Of cores X cross section mm2

Packaging Detail: | international wooden drums or according to your requirement. |

Delivery Detail: | In 15days or as the quantity you required |