Loading Port:Shanghai

Payment Terms:TT or LC

Min Order Qty:1 unit

Supply Capability:10 unit/month

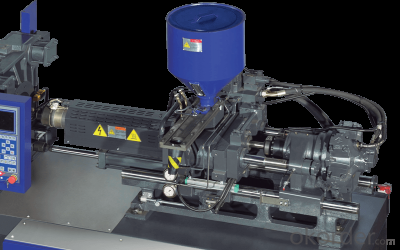

General Description of All-Electric High Precision Injection Molding Machines

Introduction

1.Reliable plastic injection machine with servo motor ,equiped with servo motor , closed loop control for pressure and flow .low noise,high precision and energy saving .

We design,manuafcture and supply our own brand of injection molding machine with clamping force ranged.

2.Inject all kinds of plastic parts, bottle preform, engineering plastic, UPVC, PVC, PE pipes fitting, omponents for automotive, household, eletronics, telecommunication, ETC

Advantages&Traits of All-Electric High Precision Injection Molding Machines

Control part:

1.It adopts imported computer for plastic injection machine , with large screen . high definiyion crystal display and human-computer interface in different languages. Through CPU independent control and individual treatment. It has raised the running speed of thr control system and alarming of successive oil temperature , thus I,proving the operating speed of the machine.

2. Closed –loop temperature control system to ensure the accuracy and reliability of the barrel temperature . The functions of cold –proof boot, alarming and parameter memory for the molding, with password protection. The injection and switch are controlled by imported ruler.

Injection part:

1.The excellent chrome , molybdenum and aluminum alloy screw and barrel have undergone the nitrilizing process, applicable to various plastic materials.

2. The injection cylinder(258T advanced) is parallel or balance for both sides of the barrel, so as to ensure the non-deviation of thr nozzle, good sealing and non-leadage. It is equipped with double guide pillar supporting system which can inject under multifarious pressure at various speeds. It also uses one-stop hydraulic pre-injection device.

Hydralic part:

It adopts the imported top quality hydraulic components, proportional control for pressure and flow.

Moulding-adjusment part:

Mold is adjusted by gear controlled by oil motor , the mold can be adjusted automatically in accordance with the setting pressure , which is both convenient and reliable.

Mold part

1.Five –fulcrum crankshaft structure , the mold and bracket structure together,with good rigidity and high-fitting precision, adopting the computerized optimized design. The mold employs finite element analysis, with double pulling and inserting device.

2.Perfroms thefunctions of super sensitive low pressure protection. The mechnical hydraulic and electrical protection have the human safety. The dismounable fill-out hopper can be installed conveniently and automatically.The moveable platen adopts a fixed durable vertical brace that is adjustable. With little friction and balanced dependable moving. Clamp opening is synchro with ejection.

Specification of All-Electric High Precision Injection Molding Machines

Item | Unit | Parameter | ||

Screw no | A | B | C | |

Screw Dia | mm | 38 | 42 | 45 |

Screw LD ratio | 23.2 | 21 | 19.6 | |

Theoretical capacity | cm3 | 209 | 256 | 294 |

Injection weight | g | 190 | 233 | 267 |

Injection Pressure | MPa | 243 | 199 | 173 |

Injection rate | g/s | 100.9 | 123 | 141.2 |

Plasticizing capacity | g/s | 14.7 | 18.2 | 20.6 |

Max. screw speed | rpm | 200 | ||

Clamping force | kN | 1280 | ||

Moving mould distance | mm | 560 | ||

Tie bar spacing | mm | 420×420 | ||

Max.Daylight | mm | 730 | ||

Min. mould thickness | mm | 170 | ||

Ejector stroke | mm | 150 | ||

Ejector force | kN | 41 | ||

Ejector bar amount | 5 | |||

Max.pump pressure | MPa | 17.5 | ||

Pump motor power | kW | 15 | ||

Heating power | kW | 7.5 | ||

External dimension | mm3 | 4500×1600×2100 | ||

Weight | Kg | 5500 | ||

Material cylinder capacity | L | 25 | ||

Oil tank capacity | L | 265 | ||

Package of All-Electric High Precision Injection Molding Machines

Wooden box packed, suitable for train or sea worthy delivery.

FAQ:

1. Why Choose us?

CNBM is a stated owned company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

3. Can you provide sample?

Yes, we can offer free sample for you.

4. Payment terms?

We can accept L/C, T/T etc.

5. Do you offer OEM service?

Yes, we can print customers’ logo on the packaging;

And the size and specification can be produced and design according to your demand.