Loading Port:China main port

Payment Terms:TT OR LC

Min Order Qty:1 set

Supply Capability:10 set/month

Description

As a kind of gantry crane, it is a special crane designed for bridge construction. It is made up of main girder, legs, overhead crane and etc. All parts are connected by high strength friction grip bolt and hinge pin, which is convenient to dismount and transport. Comparing with common gantry crane, it is convenient and swift to mount and economical practical. It is used,often, in mobile road and bridge construction unit.

What’s more, not only can two sets of girder cranes coordinate to lifting precast beam, but also one set crane with two spreaders can lift the precast beam. Each lifting capacity of both sets of girder crane usually can reach 450T. Generally speaking, the single lifting capacity can reach 900T. Equipped with legs traveling, overhead traveling crane, traveling and lifting equipment, it realizes omnibearing mechanization movement. Mainly, it is used for lifting theprecast beam to designed saving place and then lift it to the track for transportation.

Technical requirements

1. With low speed of lifting mechanism and traveling mechanism, it aims to promote the counterpoint precision and reduce the compact for girder crane.

2. With quite big inner space, it satisfies the requirement of lifting the precast beam and assembling the girder crane.

3. After it satisfies the strength, steel rigidity and stability of the main steel structure, it can be dismounted to transport.

4. It must satisfy that the two sets of cranes be on synchronous operation when the two coordinate to lift the precast beam.

Advantage

1. Equipped with a special spreader, it mainly used for loading and unloading of large-size bridges and transition.

2. The crane can realize 90°rotation, which is suitable for multi-span use.

3. The hoisting mechanism adopts four-point hoisting three-point balancing to ensure the wire-rope even stress

4. The trolley adopts hydraulic push rod, which can realize l lifting kinds of bridges, meanwhile, it can save the cost.

Operation specification

The operator must be fully trained before they begin to work. Before they begin working, the operator must know what they are going to complete and who is the guardian each day. The operator must examine the machine whether if it is in proper functioning before the work. The operator must make sure that there exists no any obstacle on the railway and inspect the wholistic technical conditions. The operator must take appointment with certifications. Before the work, the operator must make sure all electric devices, such as mechanical equipment, electrical parts, protective device, motor, hydraulic pump and other instrument, panel and joy stick(if the controller, brake and emergency switch, stopper, ring and other main accessories are out of work, it can not work). And then, you must finish the inspection record. You must inform your floor director or project engineer the moment you discover the problem. It is not permitted you operate the moving girder crane without inspection. The new installed crane must be tested and be passed in according with crane performance testing for lifting heavy load. Prior in using the main cabin. After the equipment started, you must wait almost 5 min so as to motor and other assembly unit reaching the working temperature. You can continue working after all is normal.

The operator can manipulate the equipment after you ensure the command signal. Before you start the machine, you must press the ring. It is required smoothly manipulate. After it is launched, you must drive with low speed. Then, you can speed up gradually. Before you stop the machine, you must speed down gradually. You can not stop in a full-speed rotation or stop suddenly. If you want to change the traveling direction, you must put the controller in zero position. After the machine stop totally, you can turn to opposite direction. Back off is strictly prohibited. Replacing stop with back off is not prohibited. Replacing stop with limitation is not prohibited. Replacing emergency switch with common switch is not prohibited.

Safety precautions

Aiming to insure personal safety, equipment safety and the moved girder caused by large moved girder, heavy weight and bad sight of operation, the designer focuses on following key parts when the designing scheme is researched and developed,

Controlling and operation of traveling mechanism, it adopts combining between monitoring controlling and remote controlling, which aims to observe and trace conveniently during the girder is moved.

The electric system adopts to interlocking controlling to drive six motor and electric synchronously, which can realize the both sides initiative wheel parts to rotate synchronously. It can ensure the initiative wheel parts having enough driving torque and rotating synchronously.

The hydraulic climbing mechanism adopts to ultrahigh pressure jack. Each hydraulic lock mounted on jack can prevent the hydraulic system from decompressing.

The mechanical assisting mechanism was set on supporting girder. The mechanical supporting mechanical was supported stably when the girder body is lifted at the planned height by hydraulic system, which aims to prevent the girder body from deflecting and capsizing to insure operate safely during the operation.

The Service Documentation

The documents enclosed with this quotation serve as a basis for understanding, planning and illustration.

With the delivery, you will receive the following documents for your reference unless otherwise agreed:

General layout drawing of the installation (drawing for approval)

Operating instructions

Maintenance instructions

Assembly instruction for main current supply line (if relevant)

These documents are provided in English language

We can design according to your requirement, also can supply you the technology to weld the girder in your country

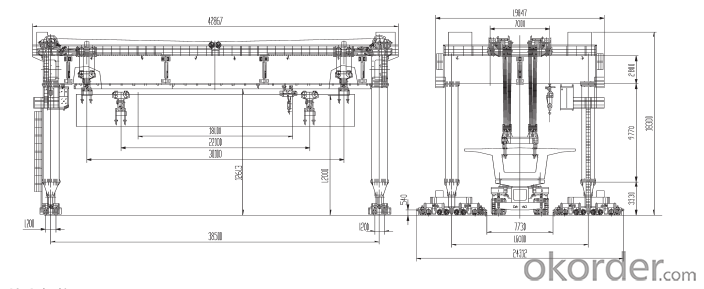

Sketch 900t Moving Girder Crane

Technical specification

Lifting capacity | T | 900(without spreader) | |

Span | m | 38.5(only 36m) | |

Lifting height | m | 12 | |

Center distance between two rails | mm | 1200 | |

Speed | Hoisting | m/min | 0.05~0.5~1(empty load) |

Traversing | Hydraulic push rod | ||

Traveling | 1~10~12(empty load) | ||

Electric hoist | Type | WH164 201~12D | |

Lifting capacity | t | 20 | |

Hoisting speed | m/min | 3.3 | |

Traveling speed | 14 | ||

Lifting speed | m | 12 | |

Duty | A3 | ||

Empty load steering | Degree ° | 90 | |

Wheel base | m | 16(Clear distance 7.73) | |

Concrete girder model | m | 20,24,32 | |

Steel track recommended | P50 P60 | ||

Max. Wheel load | KN | 225 | |

Duty | A3 | ||

Total weight | t | 505 | |

Total power | KW | 259 | |

Power source | 350 KW diesel generating set | ||