Loading Port:Tianjin

Payment Terms:TT OR LC

Min Order Qty:1 m.t.

Supply Capability:1000 m.t./month

7" CementLock™ Production Casing

Cement Bond Booster: Diamond-pattern surface increases bonding strength by 40%

Design Highlights:

External Grooves: 1.2mm depth spiral pattern

Centralizer Slots: Pre-cut every 2.5m

Easy Cutting: Laser-marked cut points

Driller's Choice:

Oklahoma operators report 50% reduction in cement channeling issues. The grooves help maintain 360° cement coverage in deviated wells.

Parameters:

Weight: 29.0kg/m

Drift Diameter: 157.1mm

Thread Type: API Short Round

Help: Free cementing best practices guide + 24/7 engineering support

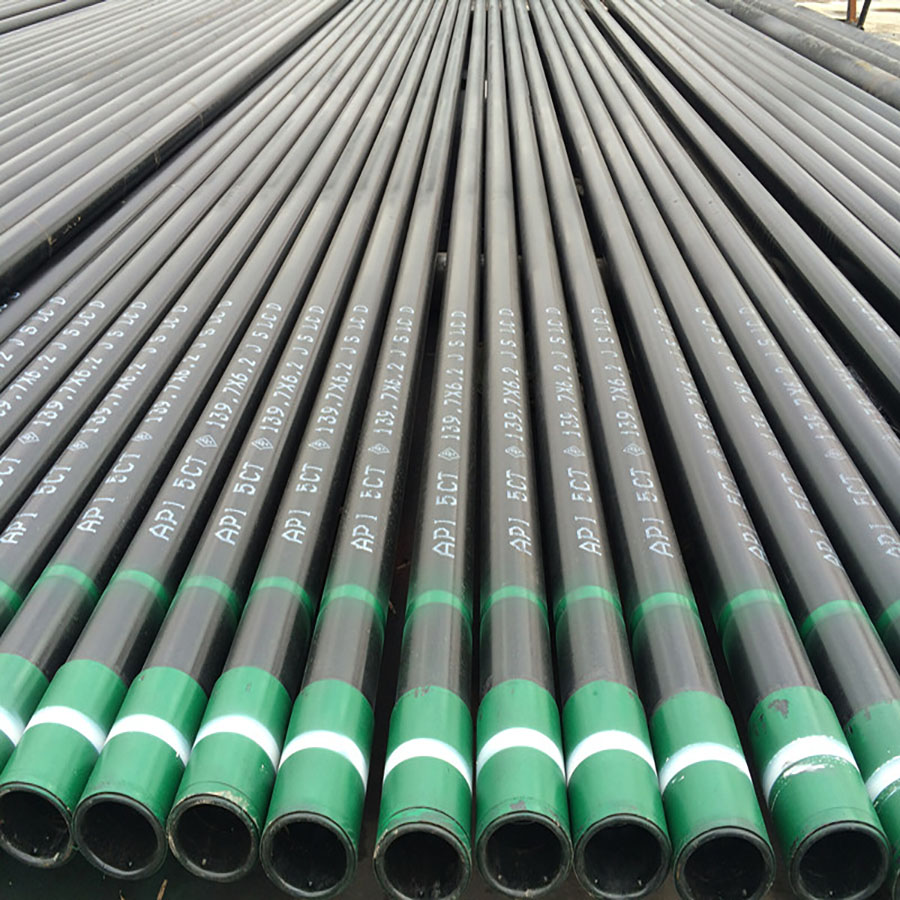

J55 Steel Deep Well Casing, P110 High-Grade Drilling Casing

petroleum casing is strictly manufactured in compliance with API 5CT standards, covering mainstream steel grades such as J55, N80, and P110. It is suitable for wellbore reinforcement and formation isolation in onshore oilfields, offshore platforms, and complex geological environments, ensuring lifecycle safety of oil and gas wells.

Size Range:

Outer diameter 114.3 mm (4.5") to 508 mm (20"), wall thickness 6.2-25.4 mm, tolerances conform to API 5CT standards (outer diameter ±0.5%, wall thickness ±10%).

Mechanical Properties:

J55 Grade: Yield strength ≥379 MPa, tensile strength ≥517 MPa;

P110 Grade: Yield strength ≥758 MPa, tensile strength ≥965 MPa;

Collapse resistance: N80 Grade ≥80 MPa, P110 Grade ≥138 MPa (tested per ASTM A370).

Thread Performance:

API round thread (BTC) sealing pressure ≥20 MPa;

Premium connections (e.g., BGT2) helium leakage rate ≤1×10⁻⁶ cm³/s (tested per ISO 13679 CAL IV).

| Content | 0.25% | 1.20% | 0.45% | 0.50% | 0.25% | 0.020% | 0.010% |

| Note: Cr-Mo alloy design enhances H₂S corrosion resistance (H₂S partial pressure ≤0.3 kPa). |

High-Temperature & High-Pressure Wells:

L80-13Cr material withstands 180°C and CO₂ partial pressure ≤1 MPa (per NORSOK M-001).

Shale Gas Horizontal Wells:

TP140TT high-collapse casing with internal pressure resistance ≥105 MPa, compatible with multi-stage fracturing.

Deepwater Offshore Wells:

9-5/8" casing passes 30 MPa external pressure test, suitable for 3,000-meter water depth.

Material Smelting:

Electric Arc Furnace (EAF) + LF refining, sulfur/phosphorus ≤0.015%;

Continuous casting billet Φ180-400 mm, central segregation ≤Class C 1.0.

Hot Rolling:

Three-roll retained mandrel mill, wall thickness uniformity ≤5%;

Online spray cooling, final rolling temperature 900±20°C.

Heat Treatment:

Quenching (920°C water cooling) + Tempering (620°C air cooling), hardness 22-32 HRC;

Sour-service pipes use HWQ process, grain size ≥ASTM 7.

Quality Inspection:

100% ultrasonic testing (UT) for longitudinal defects (sensitivity Φ1.6 mm flat-bottom hole);

Full-length hydrostatic test (50-100 MPa, holding ≥10 seconds);

Drift test with API drift mandrel (100% pass rate).

Middle East Oilfield Project:

Delivered 13-3/8" P110 casing for 4,500-meter well depth, collapse resistance 120 MPa.

7" TP140TT casing supports 30-stage fracturing, boosting single-well output by 25%.

J55/P110 Casing: High-strength, corrosion-resistant, compliant with API 5CT.

TP140TT Grade: Optimized for shale gas fracturing with extreme pressure resistance.

Deepwater Compliance: Certified for 3,000-meter offshore operations.