Loading Port:China main port

Payment Terms:TT or LC

Min Order Qty:1 set

Supply Capability:500 set/month

Column panel is a modular shuttering panel, made of high impact resistant PP plastic, for reinforced concrete columns, pile caps and walls. The panels are engineered to interconnect orthogonally in different positions, creating a “star”-shaped formwork of variable size.

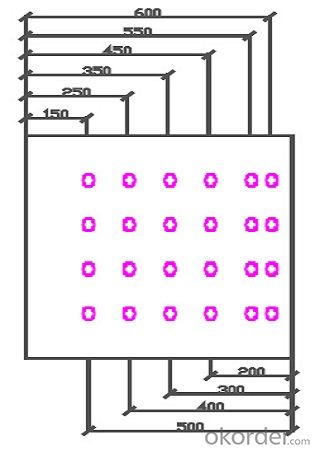

The column panels are interconnected using the standard nylon locking handles. Each panel will require 9 handles. The forming face has 6 parallel rows of fixing holes to allow the orthogonal connection of the panels in a “star” shape. The rows are placed at a distance of 100/50 mm the one from the other, allowing the forming of square and/or rectangular columns with side of 150 to 600 mm.

There is a series of holes in the middle of the panels for the passage of tie rods. The position of the holes is asymmetric to avoid conflict between crossing tie rods. All unused holes are closed with plugs.

A column 3m height is formed with 16x column panels, 8 x tie rods, 16 x washers, 144 x handles, 4 vertical steel reinforcement bars.

Different size of panels can be firmly locked by simply turn the special handles to 90 degree. The panels have rib on the back, which makes the system need not traditional wood blocks and nails. The panels have holes to fit tie rod, guarantee the strength of the whole system.

The material of modular formwork is PC ABS mixed with special glass fibers which enable panels to hold high pressures.

The system need not cut and nail due to the variety size, and nearly need no wood, the material can be recycled after broken, will not pollute the environment.

Concrete does not stick to plastic, thus the panels need no oil before using, and can be cleaned simply by water. The surface of the wall which built by modular formwork is smooth, can be left without rework.