Loading Port:Shunde, China

Payment Terms:TT or LC

Min Order Qty:1pcs pc

Supply Capability:1000 Pieces Per Month pc/month

Introduction Of 630mm Double-Side Planer With Best Quality

1. Cast iron housing frame, stable and shock absorption, NC machining center machined, provided a better foundation for cutting and feeding.

2. Specially and precisely processed main spindle with high precision imported bearings, provided a strong and healthy heart for the machine.

3. Suspended hoding claws on feeding track, accommodated different thickness or bending of the materials, provided powerful feeding capacity.

4. Equipped with manual and automatic fine-adjustment on top cutter shaft, barrels and feeding units, quick and accurate positioning. Linkage top and bottom feeding barrels, balanced and powerful feeding capacity.

Standard Configuration Of 630mm Double-Side Planer With Best Quality

1. Made from cast iron for optimal vibration absorption, the massive machine base ensures a smooth running for the cutter spindles and the feeding mechanism.

2. Positive upper & bottom feeding rollers for easy, fast and powerful material feeding.

3. Bottom cutterhead pull-out design for convenient and safe knife replacement.

4. Made from special material and specially treated, the cutter spindle is dynamically balanced, characterizes by speedy rotation, high precision and long service life.

5. Auto lubricator provides a forced lubrication to all major transmission parts and sliding parts regularly, features oil-free protection.

6. Feeding mechanism is frequency inverter controlling system, suitable for various material processing.

7. The adjustment of the movable working table is carried out at the machine side for an easy, safe and fast operation.

8. Provided with auto thickness setting device and upper pressure mechanism down limit switch. Put the material on the auto thickness setting device, down the upper pressure mechanism to set the thickness automatically. No repeated thickness adjustment needed.

9. Both the upper & down cutter spindles are designed with cutter spindle locking device,prevents the finger from being hurt during knife replacement.

10. High working precision, excellent quality and wood saving are guaranteed.

11. Provided with magnetic scale digital readout for working thickness adjustment, the working precision is up to 0.01mm.

12. The feeding pressure can be adjusted according to the working condition to prevent workpiece from sliding and avoid any pressing mark on the workpiece surface.

13. Provided with heavy duty helical cutterheads, improves the working efficiency, especially suitable for hard and moisture material processing.

Advantages Of 630mm Double-Side Planer With Best Quality

1. Top and bottom active feeding barrels structure with an overload protection, feeding more powerful and stable.

2. Equipped with short material processing device, insured smooth short pieces processing, improve waste wood utilization.

3. Imported main governor equipped with high torque reduction worm gear box, variable feeding speed adjustment to accommodate the actual demand of wood processing.

4. Heavy-duty gray cast iron bousing frame and working table, through aging treatments and precise machining, provided better shock absorption and high accuracy.

5. Feeding mechanism up and down fine adjustment, up to 10mm, highly improved processing accuracy, feeding more powerful.

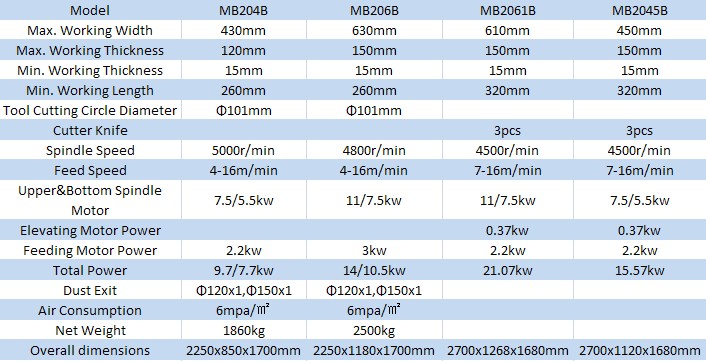

Specifications Of 630mm Double-Side Planer With Best Quality

Packing of 630mm Double-Side Planer With Best Quality