Loading Port:China main port

Payment Terms:TT OR LC

Min Order Qty:1 set

Supply Capability:10 set/month

Profile

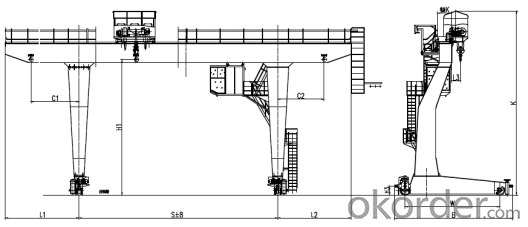

According to the shape of the landing legs, the single girder gantry crane with hook can be divided into two types, L type and C type. The form of the bridge structure includes three parts, such as dual brackets, single bracket and no bracket. The single girder gantry crane with hook is mainly made up of steel structure of bridge structure, trolley traveling mechanism and crane traveling mechanism, electrical system and other main parts. The single girder gantry crane with used outside also is equipped with rail clamping device, rail anchor device and other anti-wind devices. The steel structure of the bridge structure is mainly connected by a main girder, two landing legs(when the span is big, it adopts one rigid leg and the other flexible leg), traveling rail of trolley, lower cross beam and etc. The main girder, landing legs, lower cross beam are connected by high strength bolts. Most of the main girder adopts bias-rail box girder. Comparing with the double-girder gantry crane, the integral rigidity is weaker. The single gantry crane with hook mainly applies to open yard and along the railway to handle the materials and lifting operation. When the diameter is Q≤50t, H≤12m, span≤35m, it can adopt the described technical specification.

Static speed rigidity of the crane is ruled: the vertical natural bow in the span of the main girder caused by lifting capacity and the dead weight of trolley applies to A5, and no more than the requirement of S/800. The end girder is box girder structure.

The electric motor adopts, YZR series, dedicated three-phase electric motor. The insulation classification is F. The protective classification is IP54. These kinds of series products have a bigger overload capacity and better mechanical strength. It can be applied to those lifting equipment with the characteristic of frequently starting and braking, obvious vibration and impacting. The reduction gear adopts medium hard tooth speed reducer, which applies to the requirement of ZBJ19010. The brake adopts YWZ series hydraulic push rod brake, which applies the requirement of GB6333-86 standard. The coiling drum adopts tube structure or casting coiling block which is welded by rolled steel plate as short cylinder. After the cylindrical shell is welded, the welded joint must be inspected by ultrasonic flaw detection.

5~10/3.2t L Model Single Main Beam Gantry Crane with Hook

Technical specifications

Lifting Capacity | Main Hook | t | 5 | 10 | ||||||||

Auxi. Hook | -- | |||||||||||

Span | m | 18 | 22 | 26 | 30 | 35 | 18 | 22 | 26 | 30 | 35 | |

Lifting Height | 10 | 11 | 10 | 11 | ||||||||

-- | -- | |||||||||||

Working Class | A5 | A5 | ||||||||||

Speed | Main Hook | m/min | 11.28 | 9.6 | ||||||||

Auxi. Hook | -- | -- | ||||||||||

Trolley Travelling | 36.6 | 39.7 | ||||||||||

Cart Travelling | 46.25 | 40.1 | 39.6 | 40.1 | ||||||||

Limit Size | L1 | mm | 6700 | 8700 | 7000 | 9000 | ||||||

L2 | 7000 | 9400 | 7000 | 9300 | ||||||||

L | -- | -- | ||||||||||

C1 | 5000 | 7000 | 5000 | 7000 | ||||||||

C2 | 5000 | 7000 | 5000 | 7000 | ||||||||

Main Size | H | 12950 | 13950 | 13600 | 14600 | |||||||

H1 | 10 | 11 | 10 | 11 | ||||||||

H2 | -- | -- | ||||||||||

H3 | 577 | 660 | 660 | |||||||||

B | 8000 | 8650 | 7000 | 7500 | ||||||||

W | 6500 | 7000 | 8700 | 9230 | ||||||||

K | 899 | 999 | 1149 | 1249 | 1050 | 1150 | 1350 | |||||

L3 | 670 | 650 | ||||||||||

Max. Wheel Pressure | KN | 160 | 166 | 185 | 213 | 233 | 340 | 178 | 189 | 215 | 222 | |

Motor Power | kw | 31.8 | 40.8 | 39.5 | 48.5 | |||||||

Steel Track | 43kg/m | 43kg/m | ||||||||||

Power Supply | 3-Phase 50Hz 380V | 3-Phase 50Hz 380V | ||||||||||

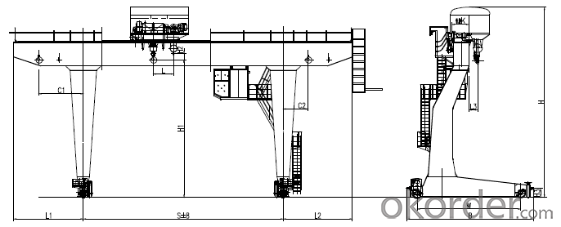

16/3.2~20/5t L Model Single Main Beam Gantry Crane with Hook

Technical specifications

Lifting Capacity | Main Hook | t | 16 | 20 | ||||||||

Auxi. Hook | 3.2 | 5 | ||||||||||

Span | m | 18 | 22 | 26 | 30 | 35 | 18 | 22 | 26 | 30 | 35 | |

Lifting Height | 10 | 11 | 10 | 11 | ||||||||

10.5 | 11.5 | 10 | 11 | |||||||||

Working Class | A5 | A5 | ||||||||||

Speed | Main Hook | m/min | 9.6 | 7.2 | ||||||||

Auxi. Hook | 16.7 | 19.4 | ||||||||||

Trolley Travelling | 39.5 | 39.3 | ||||||||||

Cart Travelling | 40.1 | 47.1 | 40.1 | 47.1 | ||||||||

Limit Size | L1 | mm | 7200 | 9200 | 7200 | 9200 | ||||||

L2 | 7800 | 10500 | 7900 | 10400 | ||||||||

L | 250 | 1483 | ||||||||||

C1 | 5000 | 7000 | 5000 | 7000 | ||||||||

C2 | 5000 | 7000 | 5000 | 7000 | ||||||||

Main Size | H | 13850 | 14850 | 13860 | 14860 | |||||||

H1 | 10 | 11 | 10 | 11 | ||||||||

H2 | 0 | 0 | ||||||||||

H3 | 660 | 762 | 660 | 762 | ||||||||

B | 8700 | 9250 | 9500 | 9250 | 10000 | |||||||

W | 7000 | 7500 | 7500 | 7500 | 8000 | |||||||

K | 1150 | 1250 | 1350 | 1450 | 1250 | 1350 | 1550 | |||||

L3 | 650 | 650 | ||||||||||

Max. Wheel Pressure | KN | 298 | 306 | 307 | 370 | 383 | 340 | 346 | 362 | 419 | 432 | |

Motor Power | kw | 71.3 | 82.3 | 76.8 | 87.8 | |||||||

Steel Track | 43kg/m | 43kg/m | ||||||||||

Power Supply | 3-Phase 50Hz 380V | 3-Phase 50Hz 380V | ||||||||||

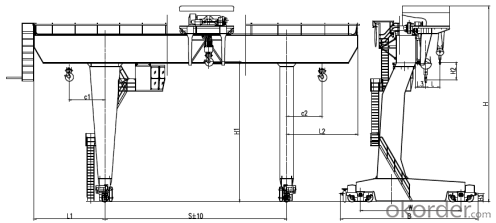

32/5~50/10t L Model Single Main Beam Gantry Crane with Hook

Technical specifications

Lifting Capacity | Main Hook | t | 32 | 50 | ||||||||||

Auxi. Hook | 5 | 10 | ||||||||||||

Span | m | 18 | 22 | 26 | 30 | 35 | 18 | 22 | 26 | 30 | 35 | |||

Lifting Height | 10 | 11 | 10 | 12 | ||||||||||

10.8 | 11.8 | 11 | 13 | |||||||||||

Working Class | A5 | A5 | ||||||||||||

Speed | Main Hook | m/min | 7.6 | 5.9 | ||||||||||

Auxi. Hook | 11.9 | 13.2 | ||||||||||||

Trolley Travelling | 38.6 | 38.5 | ||||||||||||

Cart Travelling | 48.2 | 47.85 | 39.7 | |||||||||||

Limit Size | L1 | mm | 8000 | 10000 | 8000 | 10000 | ||||||||

L2 | 8000 | 10000 | 8000 | 10000 | ||||||||||

L | 980 | 1200 | ||||||||||||

C1 | 5000 | 7000 | 5000 | 7000 | ||||||||||

C2 | 5000 | 7000 | 5000 | 7000 | ||||||||||

Main Size | H | 14380 | 15180 | 14750 | 16750 | |||||||||

H1 | 10 | 11 | 10 | 12 | ||||||||||

H2 | 800 | 100 | ||||||||||||

H3 | 763 | 670 | 660 | |||||||||||

B | 10006 | 11370 | 12060 | 12560 | ||||||||||

W | 8000 | 8500 | 8500 | 9000 | ||||||||||

K | -- | -- | ||||||||||||

L3 | 780 | 872 | ||||||||||||

Max. Wheel Pressure | KN | 457 | 470 | 370 | 380 | 395 | 350 | 355 | 359 | 363 | 378 | |||

Motor Power | kw | 108 | 116 | 145 | 155 | |||||||||

Steel Track | QU80 | QU80 | ||||||||||||

Power Supply | 3-Phase 50Hz 380V | 3-Phase 50Hz 380V | ||||||||||||

Single Girder Gantry Crane with Hook

The lifting hook of Single Girder Gantry Crane is made of forged hook, the material is DG20, which meets the requirements of GB100510 standard. The hooks are single hook type. The hook is equipped with anti slip device. The wheel is cast steel wheel, which conforms to the standard of GB4628-84 "overhead crane cylinder wheel".the break wheel of hoisting mechanism, the texture should in the below of GB699 45 steel or specified in the GB11352 ZG340-640 steel. The hardness of the surface heat treatment is 45-55HRC, and the hardness of the deep 2mm is not less than 40HBC. Steel wire rope adopts high temperature resistant, 6W (19) steel wire rope. In accordance with the provisions of GB1102-74 "round strand wire rope", the safety factor is selected according to the working level of the mechanism, M6:n>5.6.

Safety protection device: power distribution protection, consisting of automatic switch circuit breaker, contactor total protection components and the institutions of the distribution control of power supply is provided with a start and stop, emergency switch, power indicator, safety switch and limit switch, main circuit with short circuit, overload, pressure loss and zero protection.

The main lifting mechanism set up double upper limit to make sure that when the sling hoisting to limit position, cut off the lifting power supply, and send out alarm signal. when the traveling protection mechanism of the cart and trailer reach to the limitation , the system will cut off power supply automaticly, stop traveling, and send out alarm signal. if More machines in the same orbit homework collision guard safety facilities must be safe and effective.All doors must be set interlock protection device.When the door is open, crane power disconnected, crane operation can't start.Crane hoisting mechanism is set the overload limiter, when load rated lifting weight 90%, a reminder alarm signals, when the weight is more than 105% of the rated lifting weight, delay shutdown, when the weight is more than 110% of the rated lifting weight, lifting power will be shut off immediately, and a prohibitive alarm signals.

Features:

1,manufacture, installation is convenient, good force.

2, its weight is small, but lifting the goods through the outside leg space is relatively small.

3, simple manufacturing process

FAQ

1. What are the structural types of gantry cranes?

According to the structure of main girder of crane is divided into single girder gantry crane and double girder gantry crane. Single girder gantry crane according to the type of the supporting landing leg is divided into L type, C type two. The double girder gantry crane is divided into two types: A shape and U shape of the portal frame.

2. How to choose suitable gantry structure form?

When using a small tonnage hoist gantry crane, Q≤50t, H≤12m, S≤35m span, the single girder gantry crane can be adopted. Its own weight is small, but the hanging cargo through the leg space is relatively small. Double girder gantry crane is suitable for high level of work, high lifting height, large lifting capacity, effective cantilever large occasions.

3. why it adopts one rigid landing leg and the other flexible landing leg ?

When the span is greater than 30m, the gantry crane needs to make a rigid leg and a flexible supporting leg to compensate for the structural deformation caused by the temperature difference.

4. What are the features of single girder gantry crane?

- The stability and rigidity of single girder gantry crane is inferior to double girder gantry crane, the single main girder is not suitable for heavy lifting and high lifting occasions.

- Single girder gantry crane's weight is small, low cost. The space of the cargo through the outrigger is relatively small.