Loading Port:Shanghai

Payment Terms:TT OR LC

Min Order Qty:4 m.t.

Supply Capability:100000 m.t./month

2MM thickness cold rolled baosteel aisi 201 202 304 304L stainless steel coil manufacturers

Stainless steel is a production which not easy rust,acid resistance and corrosion resistance,so it is widely used in light industry,heavy industry,daily necessities and the decoration industry.my company long-term supply stainless steel products including:stainless steel sheet,stainless steel coil and stainless steel tube.

Specification:

| Commodity | 2MM thickness cold rolled baosteel aisi 201 202 304 304L stainless steel coil manufacturers | |||||

| Width | 1000mm,1219mm,1240mm,1500mm,2000mm or as customer's demand | |||||

| Thickness | Cold Rolled:0.3-3.0mm Hot Rolled:3.0-150mm | |||||

| Length | 1000mm-6000mm or as customer's demand | |||||

| Surface | No.1,2B,8K,BA,2D,No.4,No.6,ect. | |||||

| Material | 201,202,301,302,303,304,304L,309S,316,316L,316N,410,420,ect. | |||||

| Grade | 200/300/400 series | |||||

| Certification | SGS ISO | |||||

| Application | Construction,Industry,Kitchenware,Building,etc | |||||

| Packing | Kraft Paper and Seaworthy Wooden Pallet or according to client's request | |||||

| Place of Origin | Shanxi China (MAINLAND) | |||||

| Payment terms | L/C & T/T | |||||

| Delivery Time | Up To Order | |||||

Surface:

| Surface | Definition | Application | |||

| No.1 | The surface finiyshed by heat treatment and pickling or processcorresponding there to after hot rolling. | Chemical tank,pipe | |||

| 2B | Those finished,after cold rolling,by heattreatment,pickling or otherequivalent treatment and lastly bycold rolling to given appropriate luster. | Medical equipment,Food industry,Construction material | |||

| No.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils,Building | |||

| No.4 | Those finished by polishing with No.150 to No.180 abrasive specified in JIS R6001 | Medical equipment | |||

| BA | Those processed with bright heat treatment after cold rolling. | Electric equipment, Building | |||

| HL | Those finished polishing so as to give continuous polishing streaks by use=ing abrasive of suitable grain size. | Kitchen utensils,Building | |||

Chemical Composition(in percentage):

| Grade | C | Mn(Max) | P(Max) | S(Max) | Si(Max) | Cr(Max) | Ni(Max) | Mo(Max) |

| 201 | 0.15 | 5.5-7.5 | 0.06 | 0.03 | 1 | 16.0-18.0 | 3.5-5.5 | |

| 202 | 0.15 | 7.5-10.5 | 0.06 | 0.03 | 1 | 17.0-19.0 | 4.0-6.0 | |

| 304 | 0.08 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-10.5 | |

| 304L | 0.03 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-12.0 | |

| 310S | 0.08 | 2 | 0.045 | 0.03 | 1.5 | 24.0-26.0 | 19.0-22.0 | |

| 316 | 0.08 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 |

| 316L | 0.03 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 |

| 317 | 0.08 | 2 | 0.045 | 0.03 | 0.75 | 18.0-20.0 | 11.0-14.0 | 3.0-4.0 |

| 317L | 0.03 | 2 | 0.045 | 0.03 | 0.75 | 18.0-20.0 | 11.0-15.0 | 3.0-4.0 |

| 321 | 0.08 | 2 | 0.045 | 0.03 | 0.75 | 17.0-19.0 | 9.0-12.0 | |

| 409 | 0.08 | 1 | 0.04 | 0.01 | 1 | 10.5-11.75 | 0.5 | |

| 410S | 0.08 | 1 | 0.04 | 0.03 | 1 | 11.5-13.5 | 0.6 | |

| 410 | 0.15 | 1 | 0.04 | 0.03 | 1 | 11.5-13.5 | 0.75 | |

| 420 | 0.35 | 0.5 | 0.035 | 0.015 | 0.5 | 12.0-13.0 | 0.2-3.0 |

Application:

Packaging & Shipping

Packing :

Our Factory:

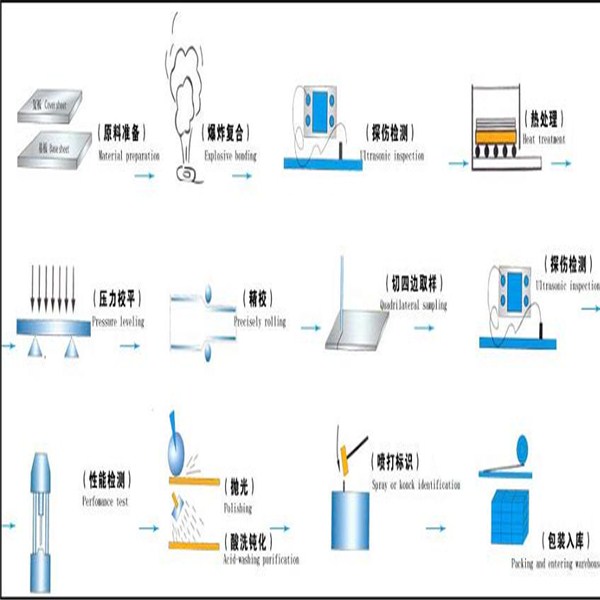

Process Flow: