Loading Port:Shanghai

Payment Terms:TT OR LC

Min Order Qty:1 pc

Supply Capability:10000 pc/month

Products Description

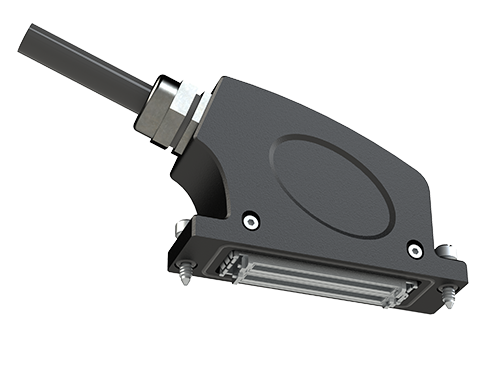

Carbon Steel Weld Probe:

Specific

Features & Applications

1.High compatibility, can be compatible with most phased array flaw detectors.

2.carbon steel weld series:

3.Thick weld inspection from 3 mm to 60 mm4.Manual or automatic detection

5.Wide thickness measurement

6.Excellent signal to noise ratio

7.Moderate constitution and large monitoring range

8.Thick plate material and weld

9.Forgings, noise or granular materials

10.Moderate constitution and large monitoring range

Specification

*The standard cable length is 2.5m/8.2ft. The phased probe can be customized,include frequency, element number and pitch,etc.

Probe Naming Rules

*The standard cable length is 2.5m/8.2ft. The phased array probe can be customized, include frequency, elements number and pitch, etc. If you have any customing requirements, our experts will work directly with you to design and manufacture customized probe, wedge, scanner.. ...

Advantages

Superior Product Performance

Test report is supplied with every probe.This form contains following contents:

High compatibility

We provide probes with different connectors according to your requirement. More connector types are available, please contact us if the connnector type is not listed below.

D19(Phasor Connector) D3(Omniscan Connector) D5(Connec 78PIN)

D6(Hypertronics 160 PIN) D7(Topaz/Zircon) D8(ITT CANNON 96PIN)

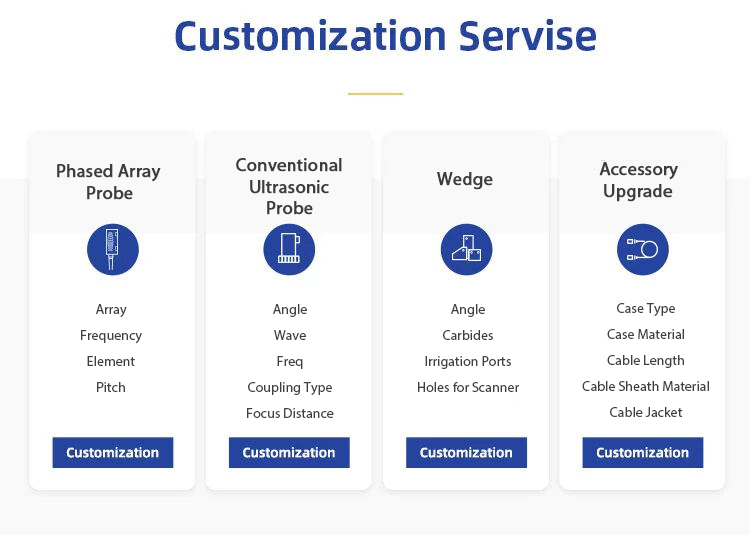

Customization Service

Customization Service

Package

M2probe provide each product with a safety box.It is external anti-fall and impact resistant. Pre-cut mesh cotton make it fully protect product safety during transportation.

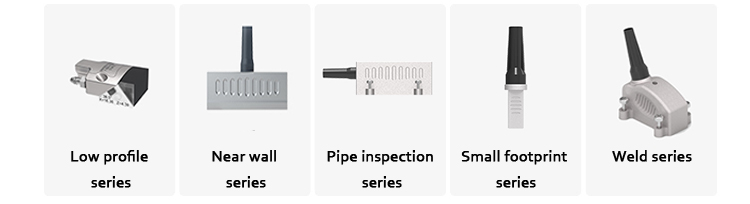

Recommend Products

Phased Array Probe

Our Factory

\

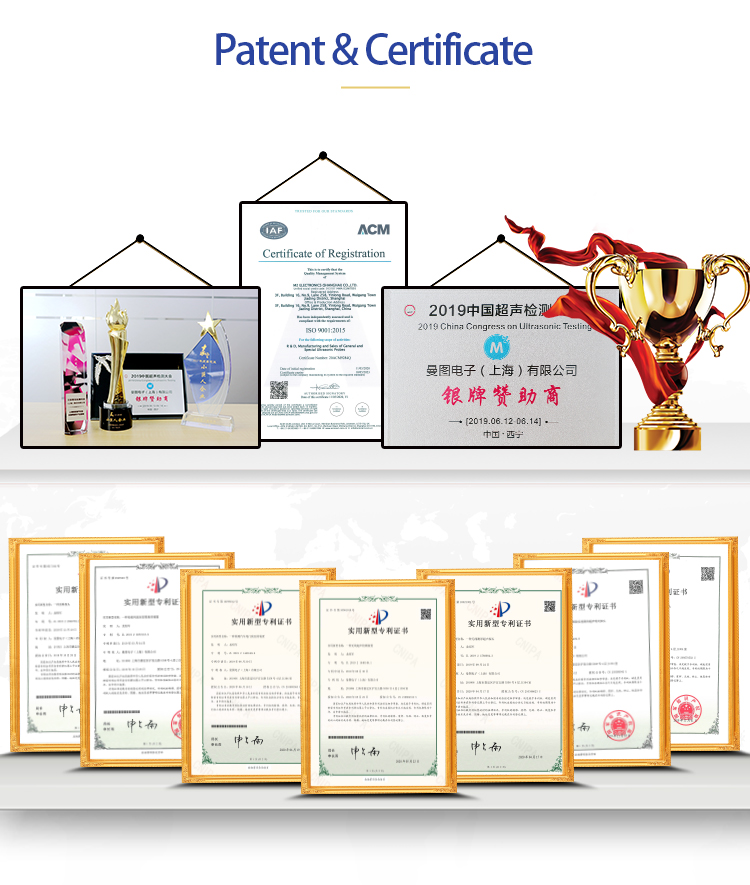

Certifications

FAQ

1.Q: Can you customize the probes, wedges, scanners according to our requirement?

A: Yes, we support all customizing requirements to meet your needs. OEM/ODM are welcomed.

2.Q: Are you factory direct supply? Can we have a visit to your factory?

A: Yes, we are factory direct supply. Our factory locates at Shanghai city, welcome to visit our factory!

3.Q: Does your factory have ISO certification?

A: Yes, our factory has ISO9001:2005 certification, we strictly follow ISO stantdards throughout whole processes from R&D to manufacturing.

4.Q: What's the MOQ? Can we buy sample to test?

A: At least 1 piece of product. Welcome to order sample.

5.Q: Can M2PROBE manufacture wedges with non-standard angles for steel and other materials?

A: Yes. The customer must specify the refracted angle desired, test material velocity, and any other important factors that may play a role in the success of the inspection. Note that, in some cases, the performance will be quoted only on a "best effort" basis. A premium will apply and/or sometimes a minimum required order quantity.

6.Q: What is the price of the product?

A: We will provide the best quality machines with best price. Never compromise performance for price.

7.Q: How long is the lead time for the product?

A: The delivery time for standard probe is usually 20 days, and for customized products, it depends on your demands of probe andtechnical difficulty.