Loading Port:Qingdao

Payment Terms:TT OR LC

Min Order Qty:1 m.t.

Supply Capability:200 m.t./month

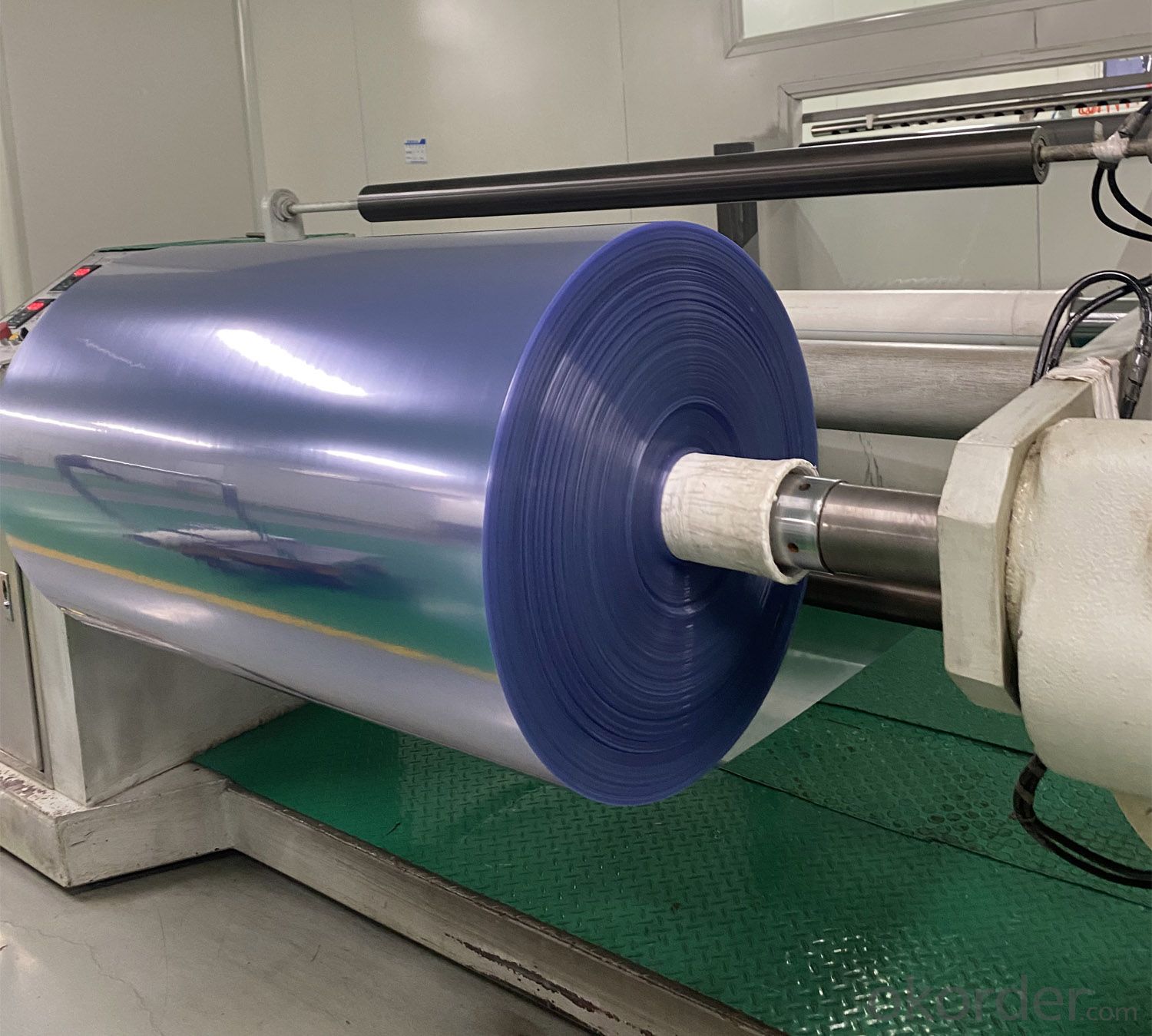

The main raw material of PVC solid pharmaceutical rigid film is polyvinyl chloride resin. The surface of this packaging material is smooth, transparent, and uniform in thickness. It is easy to form, easy to seal with PTP aluminum foil, has good oxygen barrier properties and water vapor barrier properties, and the blister is firm after forming, which can provide good support and protection for the contents.

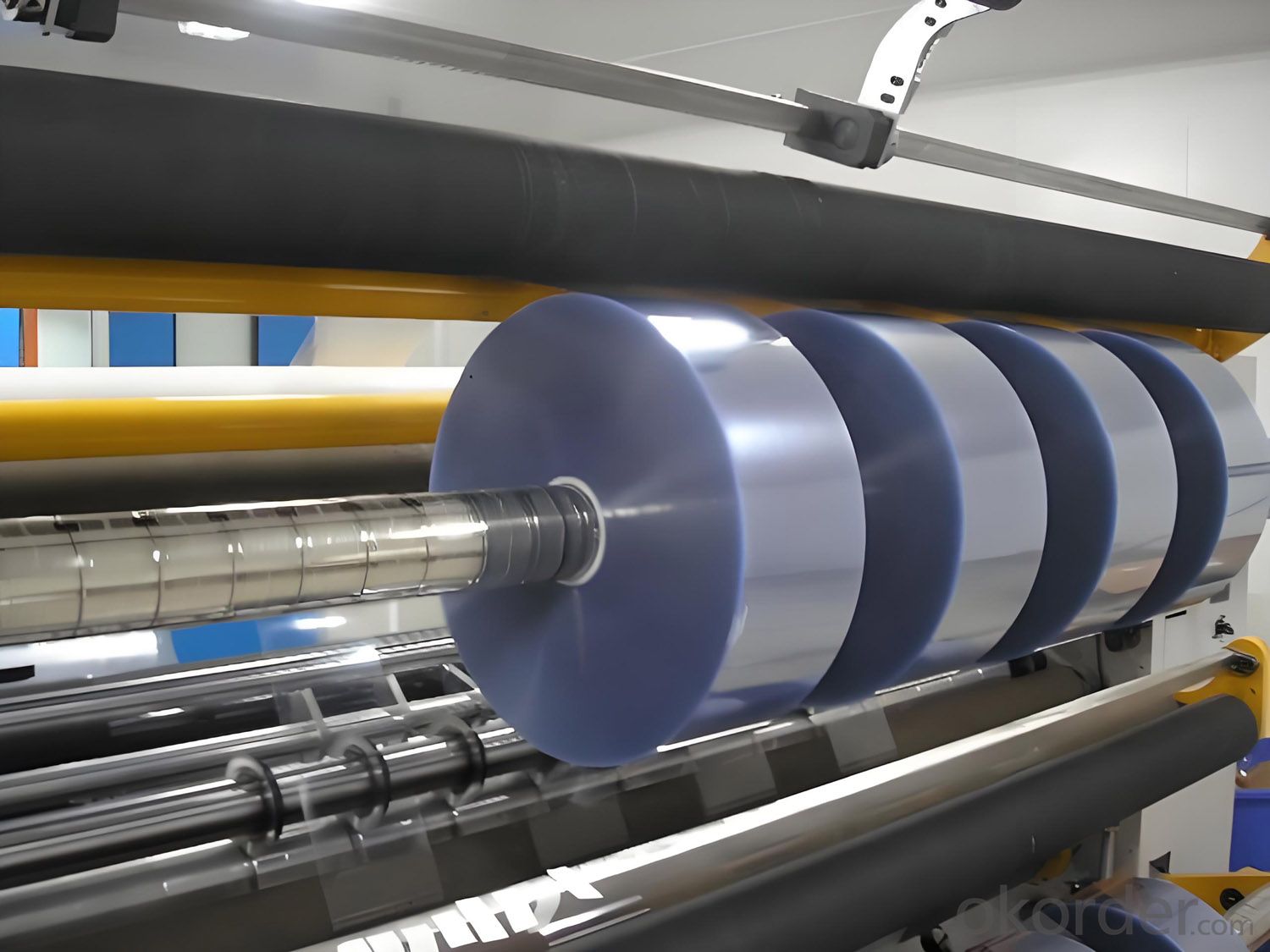

Production process:

A packaging material that meets pharmaceutical requirements is produced by adding certain processing aids to polyvinyl chloride resin through extrusion, calendering and other processing methods.

PVC rigid film specifications:

| Thickness | 0.20-0.60mm |

| Width | 75-1300mm |

| Color | transparent, glass transparent, blue transparent, amber, orange, white, blue, brown, pink, green |

| Transparency | transparent, translucent, opaque |

| Surface | bright and clean |

| Inner diameter | 76/152mm |

| Outer diameter | 200-700mm |

| Application | tablets, packaging capsules, pills, injection trays, blister packaging |

Development prospects:

In domestic PTP aluminum-plastic blister packaging, PVC rigid films account for more than 95%; the foreign trend is also dominated by PVC rigid films, accounting for about 60%, but the growth rate of composite sheets is 3-4 times that of a single material, and is rapidly becoming the mainstream. New materials such as PP, PET, and PS have emerged, but their comprehensive performance and appearance are not as good as PVC.

Advantages of PVC rigid films for pharmaceutical packaging:

1. High transparency: easy to observe the status of the medicine in the package.

2. High barrier properties: blocking moisture, oxygen and other gases, extending the shelf life of drugs.

3. Excellent impact resistance: protect the safety of drugs during transportation.

4. Chemical stability: good resistance to common chemical substances, not easy to react with drugs.

5. Good processability: easy to thermoform, suitable for drug blister packaging production.

6. Non-toxic and sterile: PVC rigid films are produced by calendering process, with non-toxic and sterile characteristics, suitable for drug packaging.

Application areas of medicinal PVC rigid films:

1.Drug blister packaging: blister packaging for solid drugs such as tablets and capsules to extend their shelf life and safety.

2.Liquid drug packaging: such as infusion bags, blood bags, etc., to ensure the sterility and stability of the product.

3.Medical device packaging: protective packaging for medical devices such as syringes and infusion tubes.

Production workshop:

Production workshop:

We has a domestically technologically advanced six-roller calendering production line and a "D-level" clean production workshop; an annual output of 25,000 tons; selected high-quality imported raw materials, pay attention to every production detail, and provide pharmaceutical companies with the most cost-effective packaging materials.

Package