Loading Port:Shanghai

Payment Terms:TT OR LC

Min Order Qty:10 pc

Supply Capability:2500 pc/month

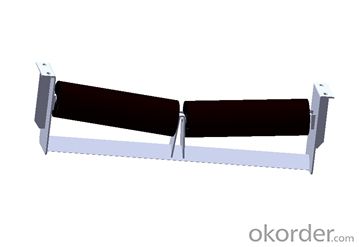

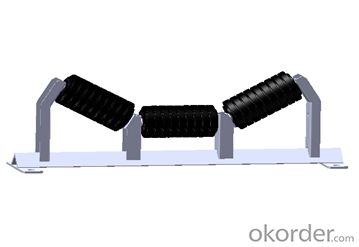

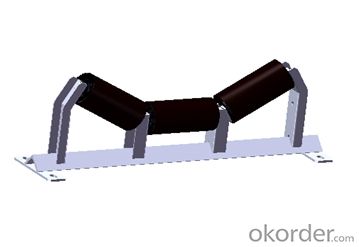

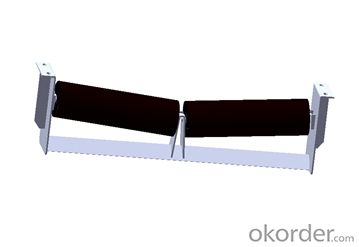

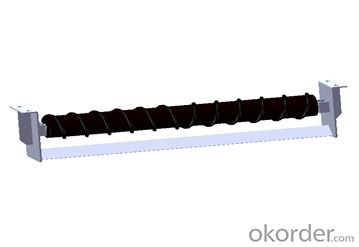

Usually, frames are trough type, made by channel steel, and some are using pipe steel. Frame sizes correspond to rollers or depend on customers' requirements to manufacture. Rollers and frames consist of idler which rollers are supported by frames and installed in different angles to meet function demand. To maintain normal running of conveyor, the frames have to be enough rigidity and intensity.

The main products of the company for six series products: roller series, roller series, stand series, the conveyor belt series, conveyor series, other machinery accessories. Including roller series products constantly upgrade, conform to the market demand to produce different kinds of roller, for example: carrying roller, cushioning, roller, nylon roller, self-aligning roller, tank type roller, etc.

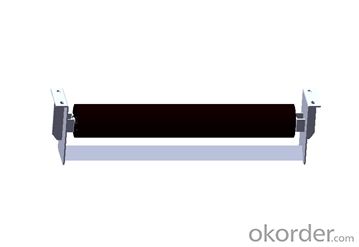

Roller support:

Roller bracket structure is simple, solid, generally installed in the belt conveyor, with many types of large number of features. The roller support can fix the roller and support the belt, it is the important support structure in the belt conveyor. Quality materials processing from the roller bracket also has a stable performance, long life and other characteristics!

Advantages of the roller bracket:

(1) roller bracket structure is simple, stable, light weight, strong support, flexibility, small friction, long life is similar products 2-5 times.

(2) the quality of the roller bracket to ensure the fixation of the roller at the same time, to ensure that the roller radial runout; flexibility and axial movement in the stable range.

(3) high quality roller bracket steel structure, spray anti-rust paint, can effectively dust, water, corrosion resistance to the external environment, anti-aging ability increased by 50% or more!

(4) roller support to provide support for the belt at the same time, but also for the belt to provide correction, tune, to prevent the role of deviation.

(5) roller bracket, the production process is simple, strong weight, easy to install and maintain, greatly reducing the production and maintenance costs! Roller bracket: roller bracket structure is simple, solid, generally installed in the belt conveyor, with a large number of types of features. The roller support can fix the roller and support the belt, it is the important support structure in the belt conveyor. Quality materials processing from the roller bracket also has a stable performance, long life and other characteristics! The type of roller bracket: roller bracket in the use of belt conveyors, with a variety, a large number of features. The roller supports are classified according to the type of roller used, their use and structure. The common type of roller supports are self-aligning roller bracket, deflecting roller bracket, slotted roller bracket, H frame, hanger Wait.

Roller bracket Use:

(1) fixed roller: high-quality roller bracket design is reasonable, more convenient loading and unloading roller, roller in the fixed at the same time, to ensure the flexibility of roller! The radial runout and axial movement of the idler is controlled within a reasonable range.

(2) support belt: roller bracket using high-quality steel processing, rigorous process of welding from the roller bracket, not only the standard specifications, and solid structure, can provide stronger support to ensure the smooth roller and belt conveyor. (3) to prevent deviation: roller bracket in the process of running the belt can make some adjustments on the belt to play an effective

Of the tune in the role, increase belt service life.

(4) wide use: light roller bracket structure, the process is simple, long life, low maintenance costs. Is a widely used affordable durable stent structure.