Loading Port:Guangzhou

Payment Terms:TT OR LC

Min Order Qty:100 pc

Supply Capability:10000000 pc/month

Rare earth Neodymium magnets (NdFeB) have been available for industrial application since 1984. Neo magnets have extremely high magnetic energy and therefore are used in applications which require high powered magnets, as well as applications where size and weight reduction are of interest or need to be considered. These qualities have made NdFeb magnets preferable over the commonly used larger and less powerful Ferrite magnets.

The main raw materials NdFeB permanent magnets are rare earth metal-Neodymium (Nd) 32%,metal element Iron (Fe) 64% and nonmetal element Boron(B) 1% , and some small amount added Dysprosium (Dy), Terbium(Tb), Cobalt (Co), Niobium(Nb),Gallium (Ga),Aluminum (Al),Copper (Cu) and other elements. Ternary system neodymium permanent materials are of Nd2Fe14B compound as a matrix, its compositions should be similar with the molecular formula of compound Nd2Fe14B, but, when it is proportioning according to the composition of Nd2Fe14B compound, the magnet performances are very low, and even without magnetic, just on the actual magnets, when the content of neodymium and boron are more than on Nd2Fe14B compound, we can get the better permanent magnet performances.

Neodymium magnets can be divided into three main groups:

1.Regular Neodymium

2.High corrosion resistant Neodymium

3.Bonded Neodymium (Isotropic): Manufactured by the injection of plastic material and Neodymium into a mold. This production method yields a very precise magnet which does not require further grinding and does not suffer substantial current loss.

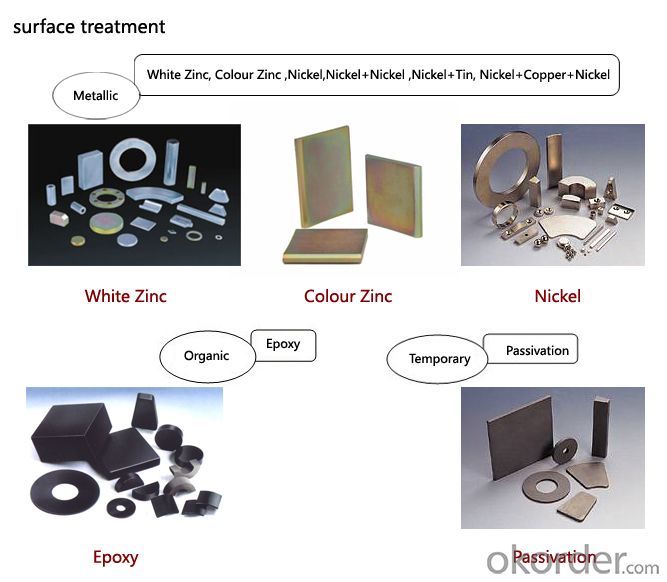

Neo magnets are known for their high temperature resistance, making them durable and functional in temperatures exceeding 200°C. This quality makes them ideal for heavy industry applications. Sintered Neodymium, however, is sensitive to oxidization and can develop corrosion, so magnets are usually coated with Nickel+Copper+Nickel,Nickel+Sn, Zn(galvanization), Epoxy and Passivation for their protection.

Characteristics of Surface Treatment

Coating Performance

| Zn | Colour Zn Cr3+ | NiSn | NiCuNi | Epoxy | Passivation |

Colour | White | Multicolor | Silver | Silver | Black | Silver |

Thickness(μm) | 6-15 | 6-15 | 10-30 | 10-30 | 10-30 | 1-5 |

Pressure Cooker Test (120℃,2atm,100%RH) | >8hr | >8hr | >24hr | >24hr | >24hr | |

Salt Spray Test (35℃,5%NaCl,1.2atm) | >24hr | >72hr | >48hr | >48hr | >96hr |