Loading Port:China Main Port

Payment Terms:TT OR LC

Min Order Qty:-

Supply Capability:-

Semi-transparent Static Film to Protect Electronical Parts

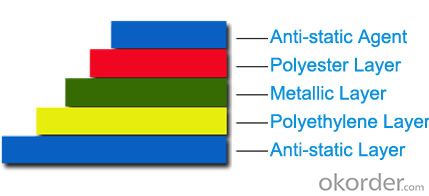

Metal in static shielding film made our of VMPET/PE films for packaging ESD sensitive devices.It is uesed for making ESD static shielding bags ,Thoes films are available with or without printing

Film construction:

Anti-static Static Shielding Film echnical Data

| Electrical Properties | Typical Values | Test Method |

| Surface Resistance | ANSI/ESD STM 11.11 | |

| Interior | <10E11ohms | |

| Exterio | <10E11 ohms | |

| Metal | <100 ohms | |

| Static Shielding | <15 nJ | ANSI/ ESD STM11.31 |

| Static Decay | <0.03 seconds | EIA 541 |

| Charge Generation | < 100 volts | ** 15kV and 12% RH |

| Physical Properties | ||

| Material Thickness | 3.6mil+/-10% | ** |

| Puncture Resistance | ≥10.0lbs | MIL-PRF-81705D |

| Tensile Strength | > 4500 psi MD/TD | ASTM D882 |

| Seam Strength | No separation | MIL-PRF-81705D |

| Optical Density | Opaque(Sliver) | ASTM D-882 |

| Heating sealing Conditions | 375°F 0.5sec.60 PSI | ** |

| MVTR | < 0.02grams/100sq. in/day | ASTM F-1249 |

| Appearance | No tears,holes,sctratches,etc. | |

| Chemical Properties | .Compliant to ROHS,REACH, | |

| Halogen free ETC requirement | ||

| Amines/Amides | Not detected | FTIR |

Antistatic Static Shield Film Roll Film specifications:

Width:450-1300mm

Thickness:0.07-0.17mm

Printing: Standard with ESD requirements,approx 50X50mm

Yellow. Date code(YYMM).

About us :

Btree is China's top 5 supplier of Static Shielding Bags and Moisture Barrier Protection. We offer a full range of

ESD Packaging solutions. Speak to our friendly team or request a brochure.

ESD Moisture Barrier Film Technical Data

| Electrical Properties | Typical Values | Test Method |

| Surface Resistance | | ANSI/ESD STM 11.11 |

| Interior | <10E11ohms | |

| Exterio | <10E11 ohms | |

| Metal | 100 ohms | |

| Static Shielding | <15 nJ | ANSI/ ESD STM11.31 |

| Static Decay | <0.03 seconds | EIA 541 |

| Charge Generation | < 100 volts | ** 15kV and 12% RH |

| Physical Properties | | |

| | | |

| Material Thickness: | 4.0mils+/-10% | |

| Puncture Strength | 10.0 lbs | MIL-PRF-81705D |

| Seam Strength | No separation | MIL -PRF-81705D |

| Heating sealing Conditions | | |

| Temperature | 300°F -400 °F | |

| Time | 0.6 -4.5seconds | |

| Pressure | 30 – 70 psi | ASTM D882 |

| Tensile Strength | >3,500 psi MD/TD | ASTM F-1249 |

| Water vaporTransmission (@100°F&90%RH) | <0.006grams/100 sq in/day | |

| | | |

| Visual inspection | No tears,holes,sctratches,etc. |

Produce progress:

Packaging