Loading Port:China main port

Payment Terms:TT OR LC

Min Order Qty:25 m.t.

Supply Capability:5000 m.t./month

Product Description

teel Shot S70-S930,

Steel Grit G10-G120,

Stainless steel shot SUS302, SUS304, SUS430,:0.5mm-2.0mm,

Steel cut wire:1.0mm-3.0mm,

Aluminum Shot,

Brown fused Alumina (Alumina Oxide),

and so on

Most competitive price with high-class quality! Free samples on request.

Steel Shot:

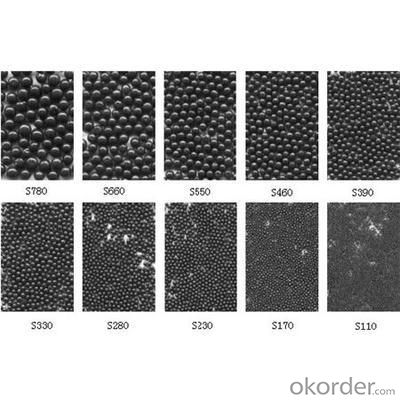

Specification: S780, S660, S550, S460, S390, S330, S280, S230, S170, S110

S780/SS2.5,S660/SS2.0 ,S550/SS1.7 ,S460/SS1.4 ,S390/SS1.2 ,S330/SS1.0 ,S280/SS0.8 ,S230/SS0.6 , S170/SS0.5 S140/SS0.4 , S110/SS0.3 , S70/SS0.2

Chemical Composition:

C:0.85-1.20%, Mn: 0.60-1.20%, Si: 0.40-1.20%, S: ≤0.05%,P: ≤0.05%

Hardness: Normal: 40-50HRC

Packing: 25kgs/bag, 40bags/jumbo bag or pallet

Application:

steel shot is used for industrial foundry, forging plant, heat treatment shop, steel construction plant, container manufacturer, ship builder, auto and locomotive manufacture

1.Surface cleaning : Castings,forgings,die-castings,steel plates,H-shaped steel ,structural steel

2.Derusting and descaling : Castings,forgings,steel plates,H-shaped steel ,structural steel

3.Surface strengthening : Gears,heat-treated parts

4.Shot blasting : Steel plates,steel profiles

5.Shot peening : Steel plates,steel profiles

6.Desanding : Steel plates,steel profiles

FAQ

Trade Information:

MOQ: 1set.

Settlement Currency: USD, RMB, EUR.

Trade mode: FOB, CIP, CFR, CIF, DDU, DDP.

Payment term: 30% deposit by T/T, the balance paid before delivery.

Delivery time: Within 15-40 days based on different type machine.

After-sale Service:

1. Installation and commissioning issue: We will send 1-2 technicians to assist with machine installation and commissioning, customer pays for their tickets, hotel and diet.

2. Warranty time:12 months from date of commissioning completion, but no more than 18 months from date of delivery.

3. Supply full English documents: including general installation drawings, pit design drawings, manual book, electric wiring diagram, electric manual book and maintenance book, etc.

4. Exported experience to many countries, such as The USA, Russia, UK, Ukraine, Australia, Malaysia, UAE, Egypt, Mexico, Brasil, etc.

5. Our shot blasting spare parts are of high quality with 20% High Chrome, ZGMn13, Mn65, etc.