Loading Port:Shanghai

Payment Terms:TT OR LC

Min Order Qty:10 m.t.

Supply Capability:1000 m.t./month

Low density.

2. Classification temperature:1610-1780.

3. Thermal insulation energy-saving effect is good.

Okorder series thermal insulation brick is an effective, energy saving, low carbon, environmental protection advanced, according to the ASTM standard manufacturing products. Okorder series products are best Li Ning and insulation in all types of industrial furnaces in the metallurgical field, aluminum, petrochemical, electric power and glass ceramic materials. They can be used as part of the working layer of thermal insulation or non - melting. Products have been widely used in the following furnace, achieved satisfactory results.

Metallurgical Industry: blast furnace, hot blast furnace, heating furnace, etc..

Petrochemical Industry: ethylene cracking furnace, hydrogen production furnace, primary reformer, heating furnace, etc..

Ceramic industry: roller kiln, kiln, etc..

Glass industry: glass furnace regenerator, etc.

Carbon industry: carbon furnace, etc..

Aluminum electrolysis industry: aluminum reduction cell, etc.

Other industries: tunnel kiln, shuttle kiln, etc..

Low thermal conductivity: more porosity will bring good thermal insulation effect, energy saving.

High crushing strength: high crushing strength, volume stability.

Low heat storage: small heat storage to absorb more heat, energy-saving effect is obvious.

Gao Chundu: iron, alkali metal impurity content is low.

The precise size: Brick size processing precision, special shape cutting and grinding, accelerate the brickwork.

1. What products do you have?

We have all kinds of refractory bricks, refractory casting materials, mortar, cement, ceramic fiber products, etc..

Or you can browse our products to choose what you need.

2. How to control product quality?

With strict quality control system throughout the material selection and production process, we have the quality of refractory materials and ceramic fiber products to meet customer requirements.

From the selection of raw materials, the quality of our control to start. The quality certificate of the raw material is required, each batch of the products are to be tested in the use of the forward line. In the production process, the quality control by the workers, and then each piece of classification, and through the quality supervision and inspection.

3. Can you give me a brief introduction to the application of your product?

My company is mainly engaged in refractories in the steel, cement, glass, ceramics, petrochemical, electric power and other industries.

4. What information do you need if I need you?

In order to select the right products, we will provide us with information, such as the United States, technical data, order quantity, product application, etc..

If you have any questions, please contact us.

High alumina insulation brick,Insulation brick,Fireclay insulation brick

Features:

1. Low thermal conductivity.

2. High strength and resistance to corrosion.

3. Low heat capacity.

4. Low shrinkage after heavy firing.

5. High insulation.

6. High refractoriness.

7. Low density.

8. Good thermal shock resistance under high temperature.

9. Thermal insulation energy-saving effect is good.

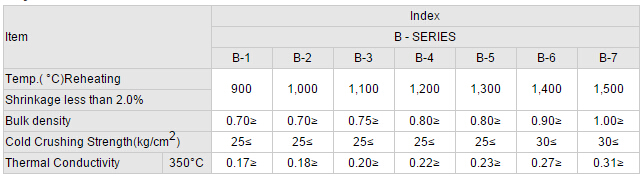

Physical and chemical index:

Application:

Insulation brick can be widely used for lining or insulation layers of various industrial furnaces and kilns in metallurgical industry, machine building industry, ceramic industry, chemical industry.