Loading Port:China main port

Payment Terms:TT OR LC

Min Order Qty:1 pc

Supply Capability:100 pc/month

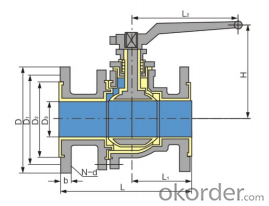

1. Q41F-10C series lining fluorine ball valve descriptions

Q41F-10C series lining fluorine ball valve is a professional design for the opening and closing of all kinds of strong corrosive medium, the body USES the carbon steel precision casting, lined with fluorine plastic ball valve and flow components are using steel skeleton outsourcing fluorine plastic.

Widely used in petroleum, chemical, acid alkali, pesticides, dyes, waste-water treatment, electroplating, electronics and other industries.

2. Application environment

Applicable temperature-20℃~120℃

Nominal diameter:(DN)20-250mm

Nominal pressure:(PN)1.0MPa

3. Model sense

EX : Q41F-10-C-65

-Q: Type code:ballvalve

-4: Code for connection type: Flange

-1 : Code for connection type: Floating direct flow type

-F: Parts which is in contact with liquid flow is made with fluorine plastic

-10: Nominal Pressure 1.0MPa

-C: Material of valve body is carbon steel with melt mold

-65: Nominal Diameter is 65mm

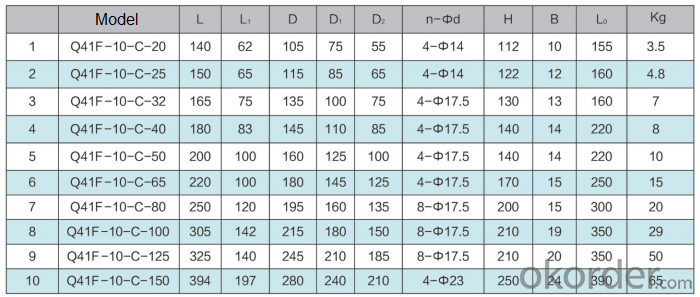

4. Model and parameter technical

5. Products features

-The fluorine lined ball valve with FEP lining layer has extremely high chemical stability and can be applied to any strong corrosion property except "molten alkali metal and element fluorine".

- Fluorine lined ball valve adopts the structure of full diameter and floating ball. The valve can be closed without leakage within the whole pressure range, which is more convenient for the ball cleaning and pipeline maintenance of the pipeline system.

- Ball parts and valve stem casting (forging) are integrated, eliminating the possibility of the valve stem bursting out of the pressure part due to pressure change, and fundamentally ensuring the safety in engineering.

- Fluorine lined ball valve structure is compact and reasonable, the body cavity space is the smallest, reduce the medium retention, in addition, special molding process, make the sealing surface density is good, combined with herringbone PTFE packing combination, make the valve to achieve zero leakage.

-Two-piece, three-piece structure can adapt to a variety of different requirements of the pipeline system and working conditions, including three-piece ball valve allows the main valve body and two sides of the body separation, ensure rapid online replacement, maintenance.