Loading Port:XINGANG

Payment Terms:TT OR LC

Min Order Qty:50 m.t.

Supply Capability:10000 m.t./month

Polymer Bitumen 60/70 For Road Construction

PRODUCT DETAILS

Asphalt is a black brown complex mixture composed of hydrocarbons of different molecular weight and non-metallic derivatives, is a kind of high viscosity organic liquid, mostly in liquid or semi-solid petroleum form, the surface is black, soluble in carbon disulfide, carbon tetrachloride. Asphalt is a kind of waterproof, moisture-proof and anticorrosive organic cementitious material.

Asphalt can be mainly divided into coal tar pitch, petroleum asphalt and natural asphalt three kinds: coal tar pitch is a by-product of coking. Petroleum bitumen is the residue of crude oil distillation. Natural bitumen is stored in the ground, and some form mineral layers or accumulate on the earth's crust. Asphalt is mainly used in coatings, plastics, rubber and other industries as well as pavement.

Penetration Grade Bitumen is a standard bitumen commonly used as a Paving Grade Bitumen in road surfacing, essential for road construction and for the production of asphalt pavements with superior properties, and it's very important once it bounds the aggregates and creates a unique cohesion and stability to the bituminous mix.

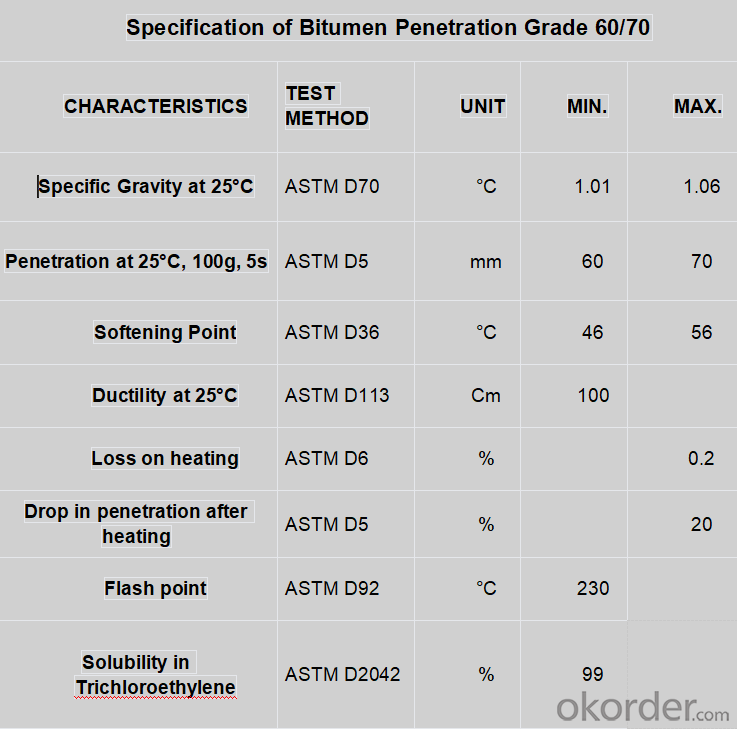

Penetration Grade bitumen are specified by the penetration and softening point test.

Uses:

Bitumen 60/70 is also used to Manufacture Bitumen mix, hot asphalt mix for bases and wearing courses, cutbacks, Emulsions and Modified

SPECIFICATIONS

NOTE:

Technical specifications and commercial terms & conditions are provided according to the specific demands of the customer.

If you have any specific technical parameter requirement, please contact our sales team.

Performance and Characteristics of asphalt emulsion plant:

1. Adopts automatic control system, automatic monitor and adjust the asphalt content. This equipment using automatic mixing tank breasts, you can alternate drainage, in order to achieve continuous production. Valve pneumatic (electric) control, thereby reducing the labor intensity and improving work efficiency;

2. High efficiency heat exchanger can cool the finished emulsion asphalt from high-temperature asphalt emulsion to room temperature, thereby improving the storage stability; The heated cooling water can be used in emulsified asphalt production, eliminating the need for water heating costs. The whole process is environmentally friendly;

3. Thermal oil heating electric heating system heated alone and can realize automatic temperature control. The thermal oil heating system is mainly used to provide heat of warm-up and production process for temperature. Replaced the traditional way of baking blowtorch, quick, easy and efficient;

4. The core part emulsifying machine during the asphalt emulsion process was reached and developed by our company, it adopts unique stator and rotor clearance adjustment structure, can maintain the stability of small gap. After special treatment of the stator and rotor has a strong resistance to abrasion and corrosion resistance, thus ensuring the effectiveness and stability of the emulsion;

5. Adopts PLC control system. Frequency control motor to adjust the asphalt pump speed to regulate the water flow through the electric milk regulating valves, can more precisely control the content of emulsified asphalt bitumen;

6. All materials in contact emulsions are made of stainless steel, has a strong resistance to corrosion, can be applied to different types of emulsified asphalt production.