Loading Port:China Main Port

Payment Terms:TT or L/C

Min Order Qty:1 set set

Supply Capability:100 sets per year set/month

General Information of Multifunctional PU sandwich panel continuous line

We can design the line to make different kinds of panels in appearance, for wall panel and roofing panel with various joint designs.

Sandwich panel, as a new building material shows excellent performance on insulation. It is taking the place of brick to be a main material for building now.

Technical Data of Multifunctional PU sandwich panel continuous line

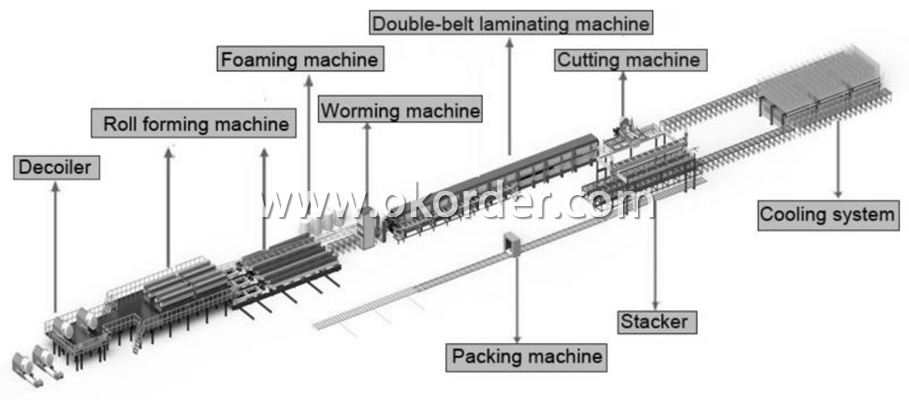

1. The Manufacture Speed of Sandwich Panel: 8.6m/min( frequency conversion to adjust speed)

2. The Thickness of Sandwich Panel: 30-200mm

3. The Thickness of Steel: 0.4-0.8mm

4. The Length of the Production Line: about 120 meters

5. The Total Power of the Production Line: 350 KW

6. The Length of the Double Belt Conveyer: 24m

PU Sandwich Panel Continuous Line

1 The equipment is accurate and durable.

2 The tape mechanism has a tension control device, enabling the overlay material evenly into the mould, to make sure the piece has a smooth surface.

3 The side block and adhesive tape recirculation device can guarantee the sealing of the piece and its demolding.

4 The double-crawler laminating system is of pressure proof, and can achieve a continuously automatic production and limit the foaming material within the mould, ensuring a stable feature in product size.

5 The following conveying and cutting systems can work simultaneously to produce plates of any length.

Working flow of Multifunctional PU sandwich panel continuous line:

Features of Multifunctional PU sandwich panel continuous line:

1. Beautiful appearance, low noise, high efficiency

2. Multiple functions: could produce 4 kinds of panel, wall pane, roof panel, cold room panel, and garage door panel.

3. The line employs advanced PLC and sets the panel length and cuts the panel automatically.

4. The main body is welded with type "H" section steel as its material, strong strength.

5. The roll forming machine is adjustable, the suitable width range is 600-1250mm

6. The roller martial is medium carbon alloy steel, with high quality.

7. The length of double belt laminating machine could be made according to customers’ needs.

Technical Parameters of Multifunctional PU sandwich panel continuous line:

ITEM | UNIT | PARAMETER |

Effective length of laminating machine | mm | 18000--36000 |

Effective width of laminating machine | mm | 1200 |

Effective height of laminating machine | mm | 20--100 |

Laminating machine temperature control range | °C | ≤80 |

Foaming casting machine flow | Kg/min | 6--25 |

Anti-pressure capability of laminating machine (25°C) | Mpa | 3 |

Anti-pressure capability of laminating machine (70°C) | Mpa | 2.8 |

Suitable production thickness | mm | 20--100 |

Capacity | m³/24h | 200 |

Dimension L*W*H | Mm | (40000--60000)*3000*4000 |

Installed power | KVA | 45 |

Total weight | Tons | 40--72 |