Loading Port:Tianjin

Payment Terms:TT OR LC

Min Order Qty:1 m.t.

Supply Capability:20000 m.t./month

General Information of Low Porosity Fireclay Brick

CMAX high alumina firebricks are classified according to alumina content ranging from 48% to 90%.

Feature of Low Porosity Fireclay Brick

Low thermal conductivity

Excellent acid and base slagging resistance

High refractoriness

Excellent thermal shock resistance

Excellent mechanical strength

Application of Low Porosity Fireclay Brick

CMAX high alumina bricks are commonly used in blast furnace, hot blast furnace, the roof of electric furnace, teeming ladle, rotary kiln, regenerator, etc

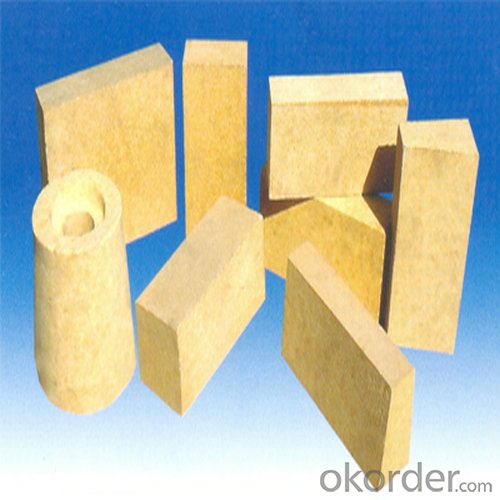

Images of Low Porosity Fireclay Brick

Technical Data of Low Porosity Fireclay Brick

LOW POROSITY FIRECLAY BRICK

--

DN-15

Chemical Composition (%)

Al2O3 ≥42

Fe2O3 ≤1.65

Bulk Density (g/cm3) ≥2.3

Porosity (%) ≤15

Cold Crushing Strength (Mpa) ≥60

Refractoriness(℃) ≥1750

Reheating Linear Change (1400℃*2h)(%) -0.2~0

Refractoriness under load (T0.6)(℃) ≥1450

Company Introduction

Who CNBM is

CNBM is a Fortune 500 and a governmental owned National Building Material company in Beijing, China.

What CNBM Can Do

We can supply ALL KINDS OF REFRACTORIES BRICK/CASTABLE and CERAMIC FIBER PRODUCTS in high quality and competitive price.

What Certification CNBM Have

FAQ

If I need your offer, what information do you need?

In order to choose suitable products, it will be appreciated to provide us the information, such us specification, technical data, order quantity, products application etc.

If any question, please contact us freely.

How do you control the products quality?

With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control are conducted by workers and then each piece will be sorted and examined by quality supervisor.

I’m not satisfied with the refractory materials I used before, can you propose more suitable pro

Yes. Please give us the problems you faced, your requirements and the technical data of the products you used before. That we will give you our suggestion and propose the solution based on your special requirements.

What’s the lead time for my order?

It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks,10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

Can you offer Door-to-Door delivery?

Yes, but only for some countries such us U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

What is the minimum quantity?

There is no minimum order quantity. Depending on the item and processing, there may be a minimum production required, however we can offer a quotation based only on the quantity you need.