Loading Port:China main port

Payment Terms:TT OR LC

Min Order Qty:100 pc

Supply Capability:100000000 pc/month

LIFTING BELT ASSEMBLY

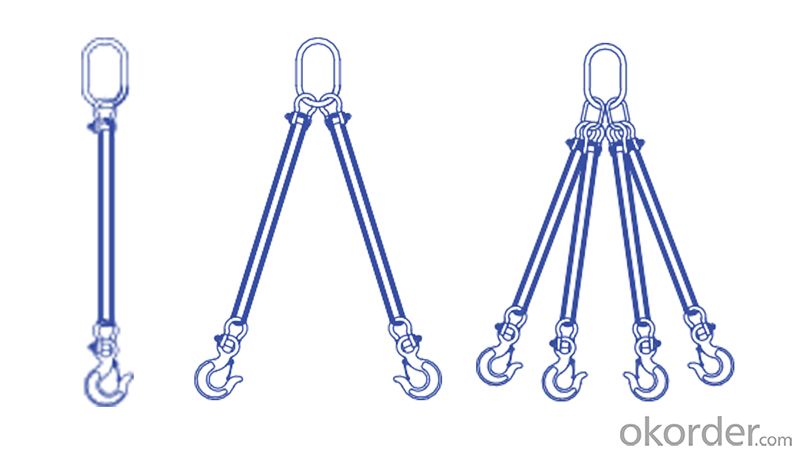

Lifting belt assembly mainly consists of master link,shackles,lifting belts,hooks and end fittings.Based on different customer demand,we can assemble into single-leg,double- leg,three legs,four legs and so on.The metal accessories can be chosen flexible according to the practical use needs,it makes convenient and safety to operate.

Note:The end fitting includes the shackle,clamp or hooks.

Ø We have master link,round link and assembly link available for main link.

Ø Connecting link including bow shackle,connecting link. Textile sling including webbing sling and round sling. End fitting including hook and others.

Ø The sling set can be assembled according to customer’s requirement.

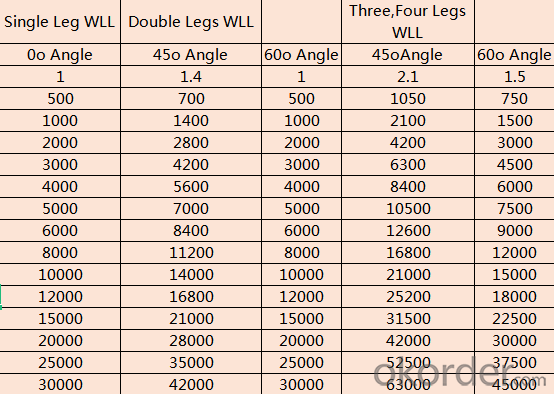

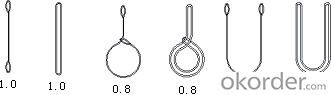

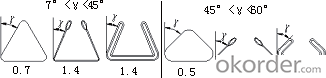

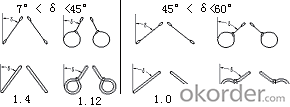

Ø Please notice the relation with angle and tonnage during usage.

Ø Safety factor 4:1,higher safety is available upon request. The graphic shows the Working Load Limit, not for standard size sling.

Main usages and applications

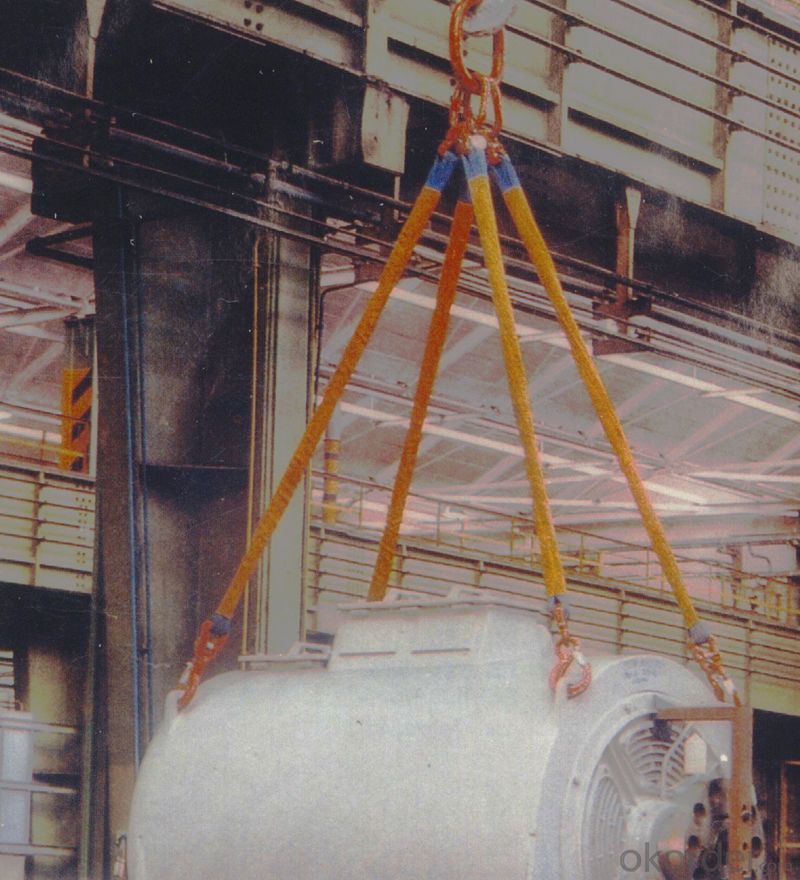

It is used to enhance the connection between the tool and hanging objects, mainly used in machinery processing, port handling, shipbuilding, electrical installation, transportation, aerospace and other hoisting field.

Product working conditions

Sling usage temperature : - 40 C ~+100 C, when using polypropylene sling

- 40 ~+80 respectively, used in high temperature environment is strictly prohibited.

Avoid molten metal, glass, fragile items, nuclear reactor, as well as other adverse environments used in the sling lifting operations.

Product working conditions

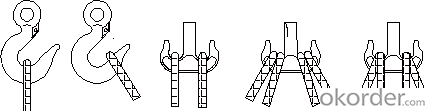

Put the sling directly into the center position of the hook, cannot be directly

hung on hooks’ tip, as shown in figure 1.

When Two slings are used, put them directly into the double hook , Put the

slings directly into the center position of the hook, as shown in figure 1.

When Four lifting Slings are used, put every two of the slings directly into the double hook ,the two sling cannot overlap, four slings to be symmetrical to the center of the hook, as shown in figure 1.

When use Two or four sling, when no special requirements on the length error , its nominal length deviation should be allowed no more than sling standards. Multiple leg lifting sling angle and calculation factor of limit load, as shown in figure 2 and table 1.

The sling can be operated as shown in Diagram 3.

Before using the Sling, there must be a trail lifting, the hanging point and the gravity of the lifted item must be in the same plumb line.

The sling,loops and metal accessories must guarantee the curvature radius,avoid the load absorption of the sling crippled due to the shear force. During using the sling, prohibit using knot to connect the slings, should use special connecting parts to connect.

Precautions for use

Sling working load limit based on the identification of the sling, overloading

use is strictly prohibited.

Cross or twist using is not allowed, knotted, twisted is not allowed.

In the process of lifting, lifting items is strictly prohibited by the collision and impact.

Check the lifting sling connectors if they are connected properly. Lifting process should try to remain stable,nobody is allowed to stand or pass through below the hanging item.

When hoisting up may not let the body of sling touch any other item, So as not to damage it.

Maintenance and Repair

Avoiding heat sources ( fire and electrical welding ) or sunlight and UV radiation under the conditions of long storage.

After being used, the sling should be placed on store shelves after use, should not be placed directly on the ground, to avoid going moldy and mouse biting. When being used under acid and alkaline conditions, immediately rinse with cold water or cleaning agent,dry storage.

Make sure the sling stored after drying,to avoid dampness and mildew.

Discard as useless

When the product appears one of the following conditions,it should be scrapped.

If the body, eye is seriously cut or scratched,1/10 of the width or 1/5 of the thickness is confirmed, Fluff up so as to the banding pattern is invisible, you can confirm that the warp injury.

Erected fluff makes the texture invisible that can be identified as warp damage.

Sewing thread breaks, cannot keep the shape of the eyes, or detachments.

Synthetic Fiber softening or deterioration, spalling, surface roughness, synthetic elastic smaller,and less intensity.

Sling moldy, acid and alkali Burns, hot - melt or burn, loose surface, and corrosion.

Hardware appears distorted, deformed, edge damage, notch injury, cracks, corrosion wear more than 10% of original size.

Period of usage, based on the usage of the sling to determine ; even if there is no apparent damage and abnormalities, if the use of the term is exceeded, the indoor use for more than 7 years ; outdoor use for more than 3 years..

Company Profile:

We are able to manufacture special slings such as high-strength type, flame retardant type, anti - slip type, wear - resistant type, acid and alkali resistant type, high temperature resistant type, fluorescent type, optical inspection type and oil and water resistant type sling.

Shipping:

1.Selling Units:Single item

2.Single package size: 30X4X5 cm

3.Single gross weight:1.210 kg

4.Package Type:Shrink-packaging + Carton Box + Pallet

Certificate:

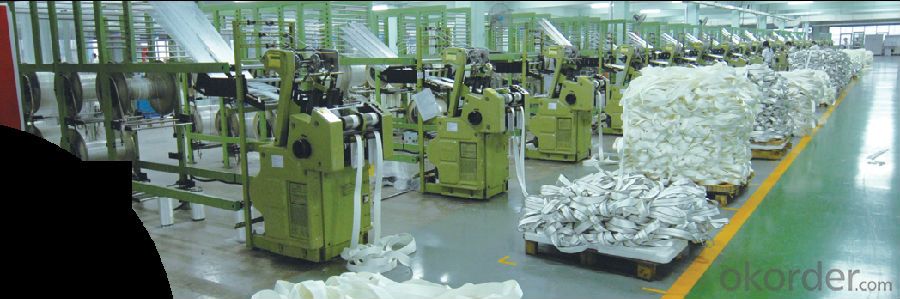

Textile sling factory is the largest base for lifting belts in the world with the production capacity "over 20000t.We have thousands of manufacturing equipments, including Muller weaving machines "from Switzerland,dyeing machines from Germany and automatic sewing machines form Japan,etc. The main products are: webbing sling, round sling, ratchet strap, assembly sling, mooring rope "and traction rope, according to different using environments, different materials would be used, "such as polyester, polypropylene, nylon, Kevlar and HMPE (high molecular weight polyethylene "material).

We are able to manufacture special slings such as high-strength type, flame retardant "type, anti - slip type, wear - resistant type, acid and alkali resistant type, high temperature resistant "type, fluorescent type, optical inspection type and oil and water resistant type sling. With characteristics like soft, light, no harm to the cargo, safety, long life and so on.

Product usage : Textile slings are widely used for lifting, pulling, bundling, fixed and other "operations in machining, port handling, marine engineering, ship, electric power, transportation, "aerospace and other fields. Achievements in scientific research:In 1997, we drafted out the industrial standard for textile "slings together with Beijing Hoisting Machinery Institute: JB/T8521-1997, which makes historic "progress for the Chinese textile sling industry. "In 2007, we revised JB/T8521.1-2007"Textile Sling – Safety - Part 1: Common use webbing "sling" and JB/T 8521.2-2007"Textile Sling - Safety - Part 2: Common use round sling". In 2009, we edited GB/T 23914.2-2009"Road vehicle mounted fixtures – Safety – part 2: "Synthetic ratchet strap assemblies", participated in writing TB/T 3123.11-2009"Rescue devices for "railway accidents - part 11: high-performance textile sling". In 2014, we participated in writing GB/T 30667-2014"Polyester and polyolefin dual Fiber rope "and GB/T 30668-2014"8 strands, 12 strands and multiflament braided Ultra high molecular weight "polyethylene fiber rope".