Loading Port:Tianjin

Payment Terms:TT OR LC

Min Order Qty:1 cm²

Supply Capability:50000 cm²/month

In the cement industry, vertical mill, roller press roller and other equipment operating environment are in a very crucial situation with high temperature and serious pollution. Its bearing needs good sealing and protection, in order to ensure the good operation of the equipment.

Our company supplies Smith, Viv, Yubu, Luokuang, China materials, Hefei and other domestic and foreign cement mill, and roller press mill roller seal and hydraulic seal, are the original factory imported products. Brand names are Italian ATS, German DE shi feng, Sweden SKF.

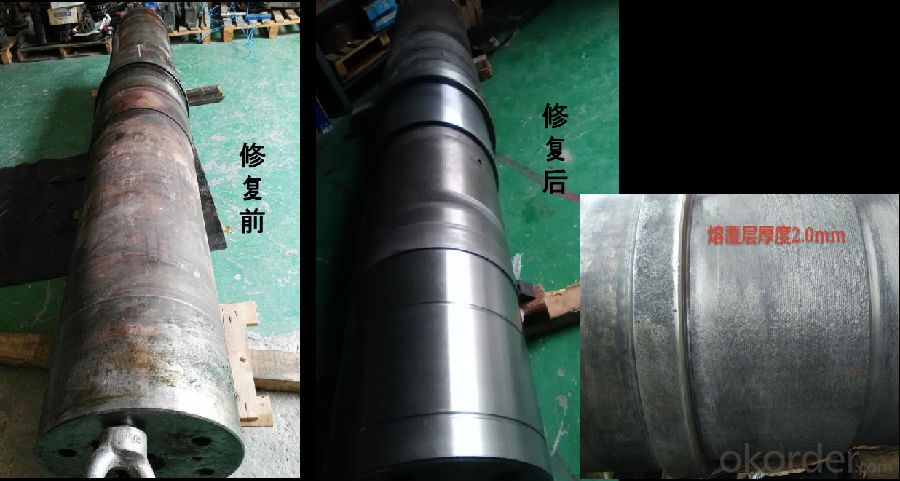

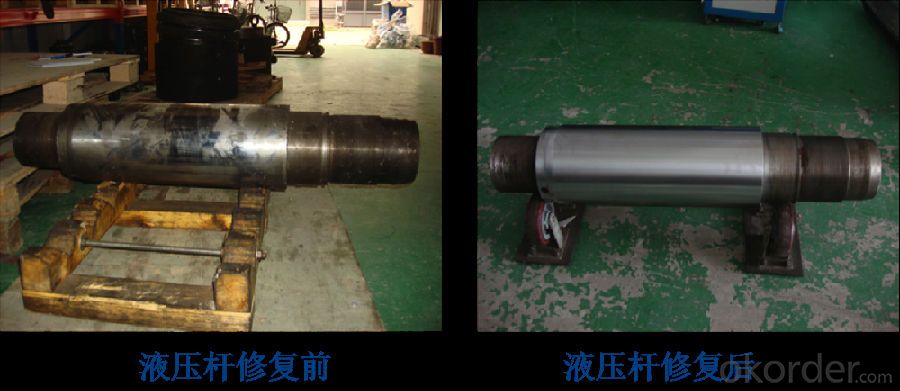

At the same time, Ruipai has been using laser cladding technology to restore and repair the worn parts of equipment in the past ten years, which not only meets the specific requirements of material surface performance, but also saves a lot of maintenance cost and time for the enterprise. Its maintenance feature is to significantly improve the wear resistance, corrosion resistance, heat resistance and oxidation resistance of the matrix surface, so as to achieve the purpose of surface modification or repair.

The goal of Laser cladding technology is to improve the performance of waste equipment, with high quality, high efficiency, energy conservation and environmental protection as the criterion, with advanced technology and industrial production as the means, different from simple "repair", also different from "renovation". Compared with new products, the waste products repaired and transformed can save 50% on cost, 60% on energy and 70% on materials.

Laser cladding Tech

No preheating, local repair, can be restored to the original size after repairing;

Metallurgical bonding, high bonding strength, anti - corrosion and wear - resistant

The repair speed is fast, the follow-up processing is simple, the repair melting pool is even, fine, without cavity, or slag