Loading Port:Shanghai

Payment Terms:TT OR LC

Min Order Qty:1 unit

Supply Capability:1000 unit/month

Ⅰ、Introduction

1.1 The machine adopts PLC and touch screen automation control, with accurate measurement, advanced structure, smooth operation, low noise, large adjustment range, the filling speed, etc. .

1.2 The delicate servo system precisely control the filling amount with precise piston stoke provides high filling accuracy, intelligent piston is designed with miner adjusting mechanism enable users to adhesive ultimate higher accuracy.

1.3 the application of touch-screen technology, the operation of the machine is more reliable, convenient and human-machine interface more friendly. Photoelectric sensors, proximity switches, etc. are used in advanced sensing elements, so no bottle no filling, plugging bottles will automatically stop and alarm.

1.4 filling way with dive style, using different materials seal rings, to meet the different characteristics of the filling material.

1.5 the machine produced according to GMP standards , all piping connections using quick way to disassemble and clean convenient location and contact with the material exposed parts are made of high quality stainless steel , machine safety, environmental protection , health, beauty, able to adapt a variety of work in different environments.

1.6 This filling machine is widely used for food, pharmaceutical, chemical, cosmetics and various industries.

2、Product features

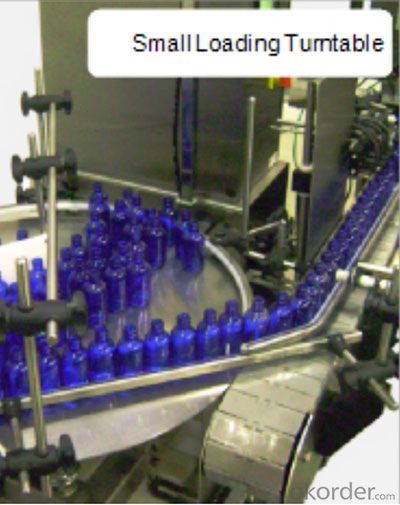

2.1、JPACKS Rotary Turntables are manufactured to increase the efficiency of any production line. Our Loading or unscrambling Turntables transfer single filed bottles onto a conveyor, enabling operators to maximize production capacity. Accumulating Turntables remove finished products from the active conveyors and assist in efficient packaging into shipping containers.

2.2、Our standard construction is comprised of a heavy duty 304 stainless steel frame.

2.3、Optional models are available for sanitary, hazardous, flammable and corrosive production lines.

2.4、JPACKS Rotary Turntables are used in the production of cosmetics, food and beverages, cleaning and specialty chemicals, pharmaceuticals, personal care and more.

3、SPECIFICATIONS

3.1、Standard Construction: Heavy duty 304SS frame, enclosure, top and rails

3.2、Standard Top Diameter: 28”, 40”, 48” or 60”

3.3、Standard Height: 36” +/- 2”

3.4、Electrical:90VDC gear motor Variable speed Nema 12 control box

3.5、Power Requirement:220V, single phase, 4A, 50-60Hz

3.6、Standard Features:Stainless steel/poly single side rail with tool-less adjustments Clockwise or counter clockwise rotation

4、OPTIONS

4.1、Double Rail System

4.2、Custom height and sizes

4.3、Custom diameters

4.4、Sanitary, hazardous, flammable and corrosive environment construction

4.5、16” Transfer Table

4.6、Half-moon Loading or Accumulating

4.7、Swivel casters for portability

4.8、Custom applications

4.9、230V, single or 3 phase, 50/60Hz

4.10、Washdown motor

4.11、Nema 4 or Nema 4x control box

5、Images

FAQ

Q1: What is your delivery time?

A: Generally, the delivery time is 45-60 days after receive the deposit, big production line may take more time.

Q2: What is the payment term?

A: We accept both T/T and L/C. Most customers pay by T/T.

Q3: What kind of after-sevices do you provide?

A: If it is not big problem, we can solve it by emails, phone etc. If it can’t work, our engineers can go to overseas to install and adjust the machine and solve the problems.