Loading Port:Ningbo

Payment Terms:TT or LC

Min Order Qty:1 unit

Supply Capability:100000 unit/month

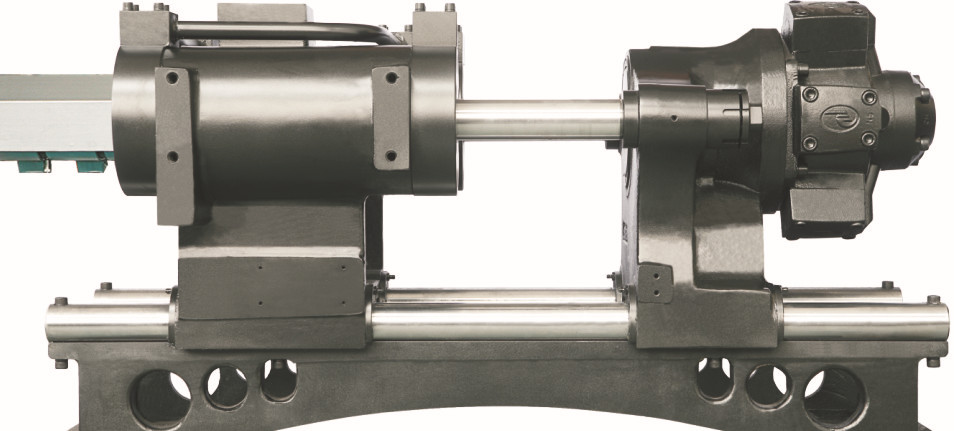

| Condition: | New | Type: | Tube Head Injection | Style: | Horizontal |

| Brand Name: | LOG | Model Number: | LOG 650S8 | Place of Origin: | Zhejiang, China (Mainland) |

| Plastic Type: | Thermoplastic | Automatic: | Yes | Injection Weight: | 2488 |

| Clamping Force: | 6500kn | Opening Stroke: | 920mm | Power(W): | 29+29kw |

| Certification: | CE | After-sales Service Provided: | Engineers available to service machinery overseas |

| Packaging Details: | 20GP,40GP,40HQ |

| Delivery Detail: | 30 Days |

Product performance and advantages:

1. Servo energy-saving system

Using the servo motor oil electricity composite structure

2. Servo motor high response feature

It costs only 0.05s for servo energy saving injection molding machines to achieve the maximum output, in comparison with conventional hydraulic injection molding machines. The response speed has been obviously increased, improving the production efficiency.

3. Unique function

Large colored screen with TFT interface

Full automatic close-loop control

Module design of hardware

Auto-tune PID temperature control

Pc interface USB, PIC, and FLASH…

Curve monitoring and analysis function

K-can data transmission (500Kbit/s)

On-line central monitoring function

LOG-650S8 Technical parameters

Description | Unit | LOG-650S8 | ||

international recognized models | 4640/650 | |||

injection | A | B | C | |

Tjeoretical injection volume | cm³ | 2160 | 2734 | 3376 |

Shot volume | g | 1966 | 2488 | 3072 |

Oz | 68.8 | 87.1 | 107.5 | |

Screw diameter | mm | 80 | 90 | 100 |

Injection diameter | mpa | 215 | 170 | 138 |

Screw L:D ratio | 23.6:1 | 21:1 | 19:1 | |

Scerw steoke | mm | 430 | ||

Screw rotate speed | r/min | 0-125 | ||

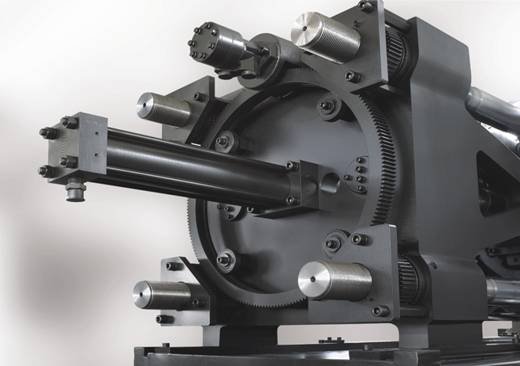

CLAMPING UNIT | ||||

Clamping force | kN | 6500 | ||

Opening stroke | mm | 920 | ||

Platen size | mm*mm | 1320*1290 | ||

Space between tie bars | mm*mm | 930*900 | ||

Maldthickness | mm | 350-910 | ||

Platen Mix stroke | mm | 1830 | ||

Ejection stroke | mm | 265 | ||

Ejcetion force | kN | 182 | ||

Power/Elcetric Heating | ||||

Hydralic system pressure | Mpa | 17.5 | ||

Pump motor | kw | 29+29 | ||

Heating power | kw | 51.6 | ||

Number of temp.conteol | 6+nozzle | |||

Other | ||||

Cycle time | sec | 6.0 | ||

Tank volume | L | 1500 | ||

Machine dimesions | m*m*m | 9.6*1.9*2.3 | ||

Weight of machine | kg | 36000 | ||

The person designing the mold chooses whether the mold uses a cold runner system or a hot runner system to carry the plastic from the injection unit to the cavities. A cold runner is a simple channel carved into the mold. The plastic that fills the cold runner cools as the part cools and is then ejected with the part as a sprue. A hot runner system is more complicated, often using cartridge heaters to keep the plastic in the runners hot as the part cools. After the part is ejected, the plastic remaining in a hot runner is injected into the next part.