Loading Port:Ningbo

Payment Terms:TT or LC

Min Order Qty:1 unit

Supply Capability:720 unit/month

Type: Tube Head Injection

Style: Horizontal

Brand Name: LOG MACHINE

Model Number: LOG250-A8

Place of Origin: Zhejiang, China (Mainland)

Plastic Type: Thermoplastic

Automatic: Yes

Injection Weight: 464-785g

Clamping Force: 2500 kn

Opening Stroke: 520mm

Power(W): 22kw

Certification: CE ISO9001

After-sales Service Provided: Engineers available to service machinery overseas

Voltage: 380V

Screw Diameter: 50-58-65

Machine weight: 8 T

Material: Stainless Steel

Screw speed: 0-180 r/min

Function: Plastic Injection Molding Machinery

Space between Tie Bar: 560X530mm

Name: horizontal Injection Molding Machine

Ejector stroke: 150mm

Injection pressure: 132-224 mpa

| LOG-250A8 | ||||

| International size rating | 1140/250 | |||

| INJECTION | A | B | C | |

| Shot volume | cm3 | 510 | 687 | 863 |

| Shot weight | G | 464 | 625 | 785 |

| OZ | 16.2 | 21.8 | 27.4 | |

| Screw diameter | mm | 50 | 58 | 65 |

| Injection pressure | mpa | 224 | 166 | 132 |

| Screw L:D ration | 21:01 | 21:01 | 18:07:01 | |

| Screw stroke | mm | 260 | ||

| Screw speed(stepless) | r/min | 0-180 | ||

| CLAMPING UNIT | ||||

| Clamping force | kn | 2500 | ||

| Opening stroke | mm | 520 | ||

| Platen size | mm×mm | 820×790 | ||

| Space between fie bars | mm×mm | 560×530 | ||

| Mold fhickness(Min-Max) | mm | 200-580 | ||

| Max.daylingt | mm | 1100 | ||

| Hydraulic ejection stroke | mm | 150 | ||

| Hydraulic ejection force | kn | 67 | ||

| POWER UNIT | ||||

| Hydraulic system pressure | mpa | 17.5 | ||

| Pump motor | kw | 22 | ||

| Heating capacity | kw | 16 | ||

| Number of femp confrol zones | \ | 5+ nozzle | ||

| GENERRL | ||||

| Dry-cycle fime | Sec | 4.8 | ||

| Oil fank capacify | λ | 380 | ||

| Machine dimensions | m×m×m | 6.2×1.6×2.15 | ||

| Machine weight | kg | 8000 | ||

product 1

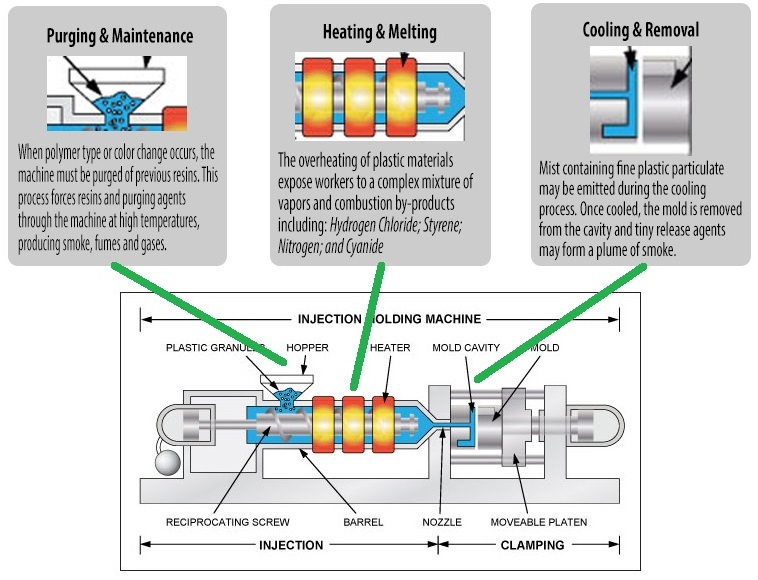

Common thermoplastic resins include:

Polyethylene PE

Polyvinyl Chloride PVC

Polypropylene PP

Polystyrene PS

Polyethlene Terephthalate PET

Acrylonitrile-butadiene-styrene ABS

Styrene-Acrylonitrile SA

Acrylic PMMA

Polyamide PA (Nylon)

Styrene-Acrylonitrile SAN

Polycarbonate PC

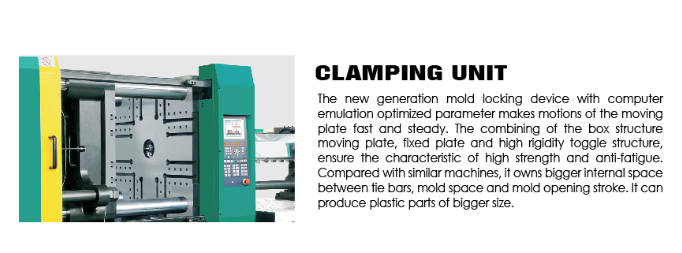

1 The mould closing unit

The new generation mold locking device and computer emulation optimized parameter makes motions of the moving plate fast and steady .When combining the box type moving plate ,fixed plate and high rigidity toggle structure ,the characteristic of high strength and anti-fatigue is secured. As compared with similar machine , it owns bigger internal spur between tie bars ,mold space and mold opening storke and may process plastic product of bigger size.

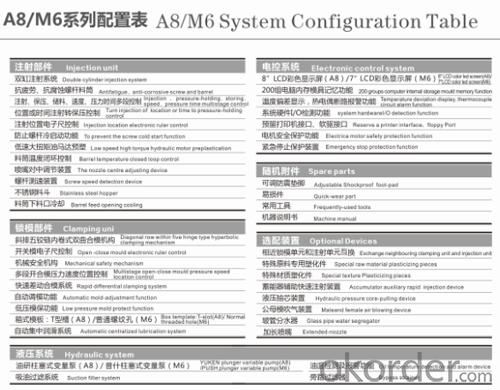

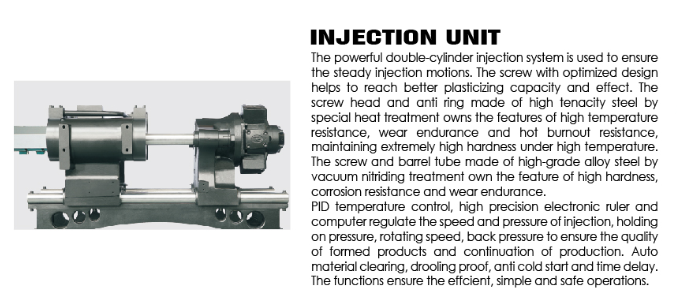

2 Computer controller

professional injection molding machine controller with software abd hardware of industrial standard is convenient to expansion and revision of performance. Adopting double CPU control makes high speed.

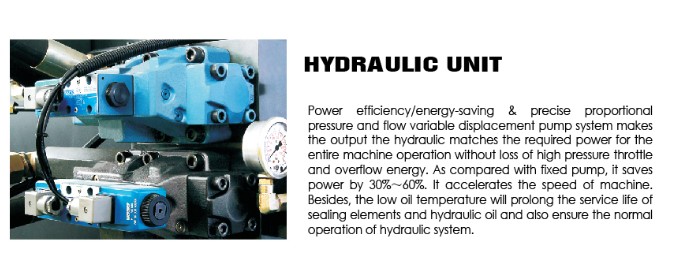

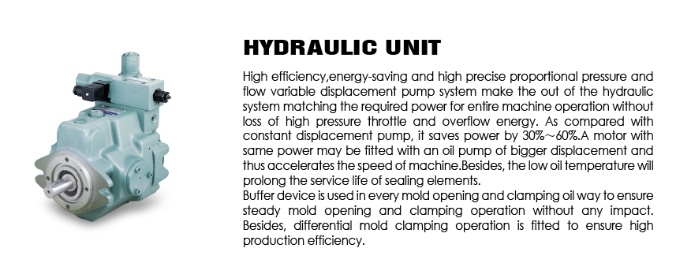

Variable Displacement Pump

1 Low Noise

Reasonable hydraulic control structure design, high integration and unipue processing in noise reduction helps machine run smoothly.

2 Oil-saving

The low oil temperature prolongs the srevice life of sealing elements .Oil cleaning equipment can filter the grease rapidly and effectively to ensure the srevice life of hydradulic elements.

3 Quick Response

The imported directly and high-response variable displacement pump achieves larger amount of emission by 20% to 25% than fixed pump driven the same motor.

4High Stability

30% to 70% energy saving compared with fixed pump under the equipment volume of work .

5 Water Saving

With no overflow and heating from variable displacement with fixed pump, 50%-75% water can be saved compared with fixed pump. Oil cleaning equipment is designed to improve the service life of hydraulic oil for 5 year.