Loading Port:NINGBO

Payment Terms:TT OR LC

Min Order Qty:1 unit

Supply Capability:10 unit/month

Product Description

1. All main structural components are made of decaying castings, and all castings are subjected to secondary aging.

2. The spindle adopts a customized ultra strong rigid spindle, with a slider size of 420mm * 420mm, and is made of high tensile strength spherical graphite cast iron material (FCD600).

3. The column adopts polyhedral and honeycomb columns with good seismic performance, high stability, more sufficient rigidity, and less deformation.

4. Install a dual nitrogen balance cylinder to ensure more stable machine operation, higher accuracy, and faster response speed.

5. The spindle gearbox is an independent research and development product of our company. Based on actual processing conditions, it is a constant temperature gearbox that optimizes the selection of bearings, gear ratio, and modulus. It is a heavy-duty reducer with good seismic resistance, long gear life, and convenient maintenance.

6. The steel plate protective cover has been changed from the original sealing strip to a copper strip sealing to prevent high-temperature iron filings from scalding the rubber strip, improving the service life of the protective cover and ensuring the precision of the machine tool.

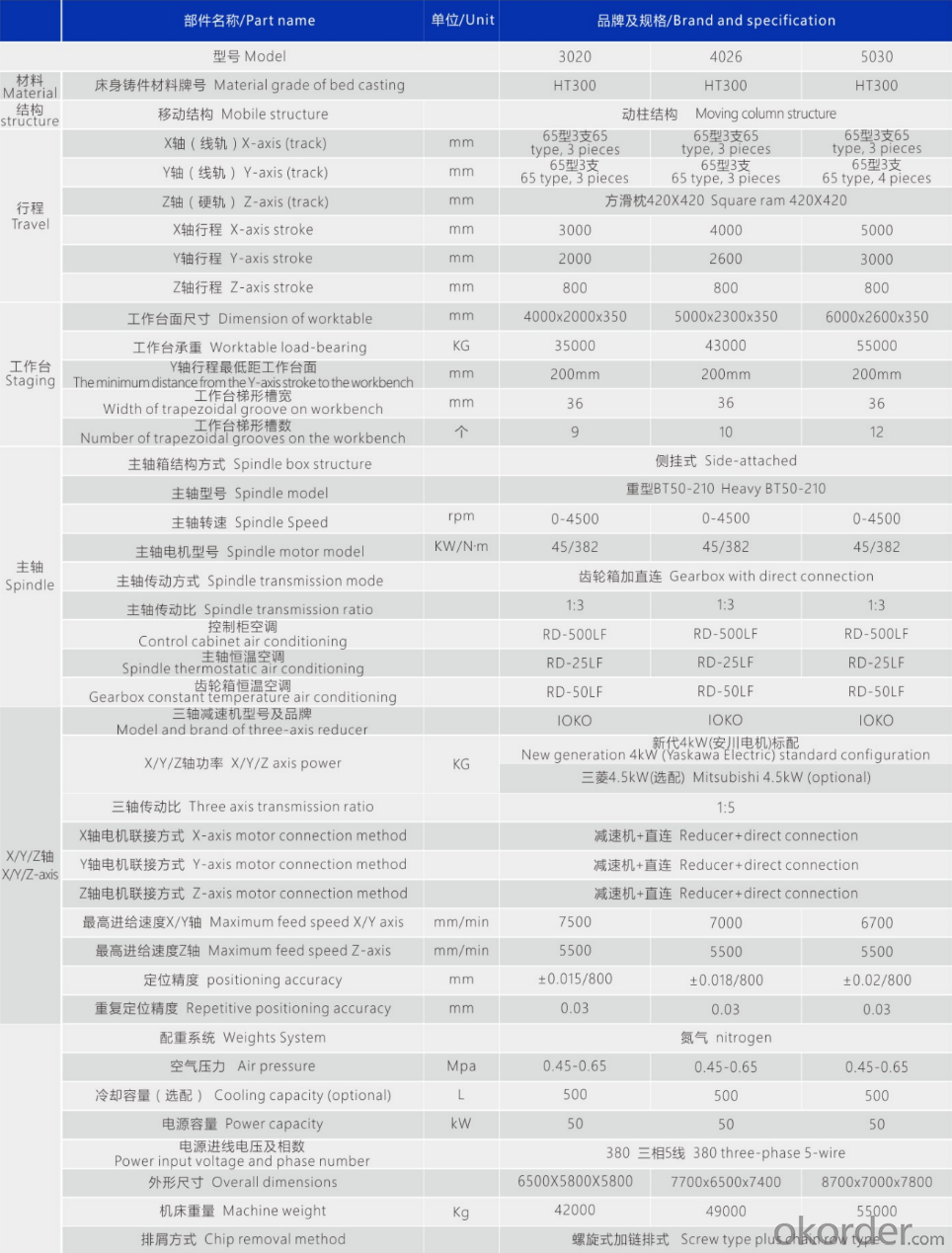

Technical Parameter

Application Area

Suitable for precision machining of large workpieces such as aerospace, automobiles, textile , molds, packaging machinery, mining equipment, etc. It can automatically complete complex machining processes such as boring, drilling, milling, tapping, etc.

Package

Global Sales Market

Cooperative Clients

Q&A

Q1. Where is your factory located?

A : Our factory is located in Taizhou City, Zhejiang Province, China.

Q2. Are you produce peeling/ polishing machine's specific parameters according to the samples?

A: Yes, we produce the machine you want by your samples or technical drawings.

Q3. What is your sample service?

A: We can supply the sample testing which client want to produce if we have ready machine in stock.

Q4. What is your MOQ of your machine?

A: Normally our MOQ is 1 set.

Q5. Do you test all your machine before delivery?

A: Yes, we have 100% test before delivery.

Q6: What is the payment term?

A: T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages before you pay the balance.

Q7: What is the normal lead time?

A: 45-180 days after we receive the deposit.

Q8: Guarantee Period?

A: 1 year. During the guarantee period, we guarantee to solve all problems may occur due to machine's quality or wrong design, and to provide all necessary spare parts for repair. We can send the technician to customer's factory if problem is serious and can't be solved by the customer.