Loading Port:Qingdao

Payment Terms:TT OR LC

Min Order Qty:-

Supply Capability:10000 /month

Carbon Fiber Tube

Light-weight&strong toughness

Various size

Manufacturer's price

Application:RC Toys/Building/Sport/Curtain

alt="Hollow Pultrusion Carbon Fiber Tube"

WELCOME TO VISIT OUR PRODUCTS!

High Strength Pultrusion Carbon Fiber Tube

SGS Verified Carbon Fiber Tube Manufacturer

3k Carbon Fiber Tube (Roll Wrapped) Matte or Glossy Finish

Brief Introduction For Carbon Fiber Tube

Carbon Fiber Tube

High strength Light-weight Straight

Quality:SGS ISO9001:2008 GIC

Various sizes Black Long-lifespan

Manufacturer's price

Application: RC Toys/Building/Sport/Furniture/Sanitation/Medical

Virtue:UV&Heat Protection Environmentally friendly

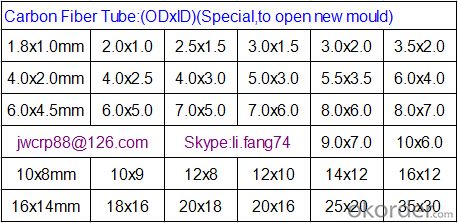

The Regular Specifications For Carbon Fiber Tube

Carbon Fiber Tube:16x10mm,25x19mm,32x28mmare also ok

Property | CF Fabric | CF Uni-Directional | Steel | Aluminium |

Density (g/cc) | 1.60 | 1.60 | 8.0 | 2.7 |

Youngs Modulus 0°(GPa) | 70 | 135 | 207 | 72 |

Youngs Modulus 90°(GPa) | 70 | 10 | 207 | 72 |

Ult. tensile Strength 0°(MPa) | 600 | 1500 | 370 | 240 |

Ult. comp Strength 0°(MPa) | 570 | 1200 | 370 | 240 |

Ult. tensile Strength 90°(MPa) | 600 | 50 | 370 | 240 |

Ult. comp Strength 90°(MPa) | 570 | 250 | 370 | 240 |

As can be seen, carbon fibre has excellent strength and low density. If these two factors are considered together, therefore looking at ‘specific strength’, then the benefits of carbon fibre look even more impressive. This is highlighted in the graph opposite.

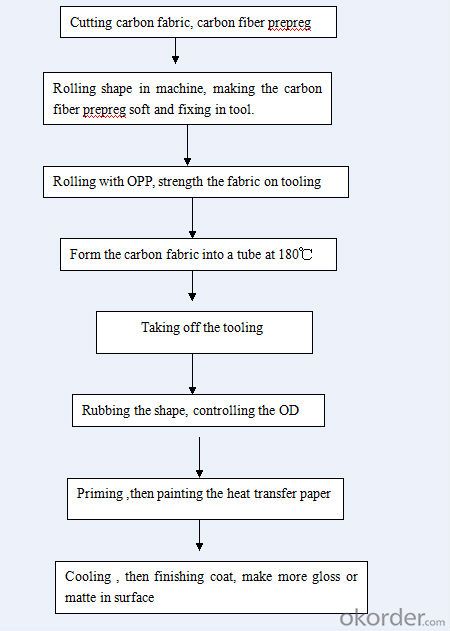

When the laminate has been designed and verified by our engineers the individual patterns are fed to our 5 metre long CNC cutting table which cuts out each pattern precisely. The materials we use are cloths which already have the resin matrix impregnated in to them, known as pre-pregs.

Next, these prepreg layers are wrapped around the male tooling (mandrels) which determine the Inside Diameter (ID) of the tube. These patterns are wrapped in an exact sequence on our machine driven rolling table to ensure consistency and accuracy of the lay-up.

The tubes are then subjected to a high temperature curing cycle under pressure in our electronically controlled ovens and finally removed from the tooling using a hydraulically powered puller mechanism.

Once complete, the raw blank is then ready to be machined and finished in line with the design specification.

The process of carbon fiber tube