Loading Port:China main port

Payment Terms:TT OR LC

Min Order Qty:1 unit

Supply Capability:15 unit/month

Trapezoidal sheets Roll Forming Machine

Technical data of Trapezoidal sheets Roll Forming Machine

Suitable Material | Q235 color steel sheet;0.3-0.7mm, 1000&1250mm coil width | |

Working speed | About 20m/min | |

Power Requirement | Main motor power: 7.5 Kw(Depend on final design) | |

Hydraulic station power: 2.2Kw(Depend on final design) | ||

Material of forming rollers | No.45 steel, plated with chrome on surface. | |

Material of cutter | Cr12 mould steel with quench treatment, HRC58-60 | |

Shaft diameter | 72mm | |

Controlling system | Mitsubishi PLC & converter | |

Total weight of machine | About 8500KGS | |

Machine''''s size | About 15m×1.8m× 1.5m (Depend on final design) | |

Shipping | 1x40GP container can load one machine | |

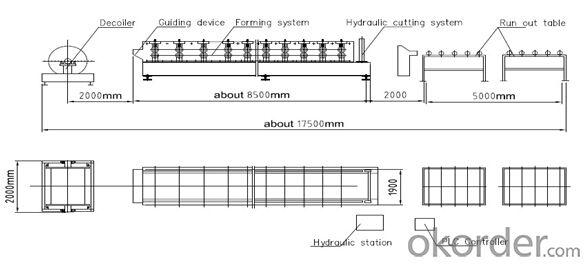

Layout drawing of Trapezoidal sheets roll forming machine

Our Trapezoidal sheets Roll Forming Machine’s advantages

| 1. Anti-rust roller: CNC machine tooled, Plated with 0.05mm hard chrome . 2. Heat treatment: Heat treatment for cutting frame to remove the steel stress, to avoid deformation. 3. Cutter blade: Cr12 mould steel with quenched treatment, long life time. 4. High precision: shafts for rollers are tooled by grinding machine at least twice. Rollers are CNC processed to ensure precision performance. 5. People originate: introduced Mitsubishi PLC with touch screen. Friendly man-machine interaction. 6. Excellent services: Technician can be sent to your factory to install the machine and train your workers. Lifttime services for our machines. |