Loading Port:China Main Port

Payment Terms:TT or L/C

Min Order Qty:20 Sets pc

Supply Capability:To Order pc/month

High Quality Forged Steel Full Bore High Pressure Ball Valve

Design Features Of High Quality Forged Steel Full Bore High Pressure Ball Valve:

Blow-out proof stem

Key lock

Anti-fire safe design

Anti-static device

Free leakage of body Sealed construction

Double block&bleed (DBB)

Emergency sealing

Automatic body cavity relief

Various driving types

Fire safe design to API 607/ API 6FA

Anti-static to BS 5351

Cavity pressure self relief

Optional locking device

Specifications of High Quality Forged Steel Full Bore High Pressure Ball Valve:

Size: 1/4"-2"

Pressure: Class150LB-900LB

Material: WCB, LCB, CF8, CF8M, CF3, CF3M, A105, LF2, F304, F316, F304L, F316L,ASTM A351

Design & Manufacture Std.: API608, ASME B16.34

Connection Ends: Threaded (Female/Female), NPT, BSP, BSPT, DIN259/2999, Butt welded, Socket welded (BW, SW)

Test Standard: API598

Structure Type: One-piece, Two-piece, Three-piece, Reduced Bore

Operated way: Lever

Suitable medium: Water, oil, steam, nitric acid, acetate acid and so on

Suitable temperature: -40 deg+150deg be able to endure high pressure

Seat: PTFE. Material and good on-off feature.

Working pressure: 1000psi

Thread standard: International BSPT, NPT, DIN, surface is flat, allow overrun

|

Nominal pressure |

PN(mpa) |

2.5 |

4 |

6.4 |

|

|

Shell Test Pressure |

PS(mpa) |

3.75 |

6 |

9.6 |

|

|

Sealing test pressure |

2.75 |

4.4 |

7.04 |

| |

|

TightnessTest Pressure |

0.6 |

0.6 |

0.6 |

| |

|

For media |

SS201 |

SS304 |

SS316 |

| |

|

Water, oil and gas medium |

Nitric acid corrosive media |

Acetic acid corrosive medium |

| ||

|

For temperature |

-40°C——+150°C |

||||

|

Product Standards |

GB/T12237-2007 |

| |||

|

Test |

GB/T13927-1992 JB/T9092-1999 |

||||

Applicable Standard Of High Quality Forged Steel Full Bore High Pressure Ball Valve:

Design Standard: API 6D, ASME B16.34, API 608, BS 5351, MSS SP-72

Face to Face: API 6D, ASME B16.10, EN 558

End Connection: ASME B16.5, ASME B16.25

Inspection and Test: API 6D, API 598

Design Description Of High Quality Forged Steel Full Bore High Pressure Ball Valve:

Double block and bleed design(DBB)

Double stem sealing. The ball can maintain pressure sealing of pipeline when it is closed or fully opened.

Shorter upper sleeve reduces bearing load and operation torue

Limit device ensures the accurate opening and closing position of the valve

The vall and stem are separated so as to reduce stem load. The stem adopts anti-blow-out design.

The sealing surface is inserted into te metal seat by polymer or plastic

The metalbacked self-lubricating PTFE bearing and PTFE thrust washers

Reduce the opening torque and prolong the service life of the valve. Stem leakage can be prevented through the emergency grease fitting.

Nickel and phosphor treatment to the parts can enhance the anticorrosive performance.

The fireproof design of metal wound gasket compassed of stainless steel and graphite can prevent external leakage.

Usage/Applications Of High Quality Forged Steel Full Bore High Pressure Ball Valve:

It can be widely used in Metallurgy, Mine, Petrochemical, Chemical, Oil & Gas transmission pipeline, Power plant, Heating power and Pharmacy, etc.

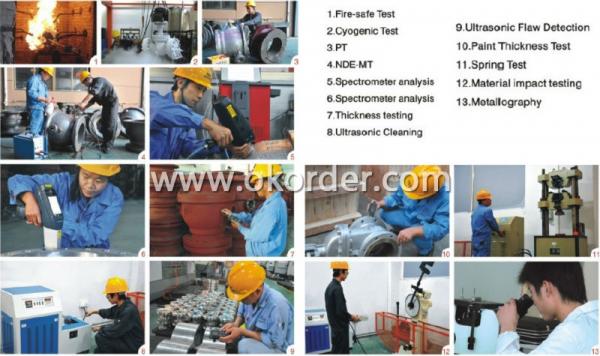

Main Test Of High Quality Forged Steel Full Bore High Pressure Ball Valve:

Packaging & Delivery Of High Quality Forged Steel Full Bore High Pressure Ball Valve:

Packaging: Inner packing: Plastic bags, Outer packing: Cartons and wooden case.