Loading Port:Tianjin

Payment Terms:TT or LC

Min Order Qty:10 m.t.

Supply Capability:1000 m.t./month

| Place of Origin: | China (Mainland) | Shape: | Brick | Material: | Alumina Block |

| SiO2 Content (%): | 22 | Al2O3 Content (%): | 65-75 | Model Number: | JDL-65/JDL-75 |

| Brand Name: | Refractoriness: | 1790 °C | Cetification: | ISO9001 |

| Packaging Details: | Fumigation wooden pallets+paper angle bead+PET strap+stretch film. |

| Delivery Detail: | More than 30 days after signing the contract |

Characteristic:

1.High-temperature resistance

2.Lower creep rate

3.High strength

4.Good thermal shock resistance

![]()

This product is made by superfine calcined bauxite, additive and high-quality combined clay. This product has good performances of hot flue scouring resistance and corrosion resistance. Its apparent porosity is lower,strength is high and its creep rate is lower, so it means that this product can well keep stability under the load and high temperature.

![]()

| Item | JDL-65 | JDL-75 |

| Al2O3 % | 65 | 75 |

| Apparent porosity % | 22 | 20 |

| Bulk density g/cm3 | 2.4 | 2.6 |

| Cold crushing strength Mpa | 55 | 60 |

| Reheating linear change % | 1450°C×2h +0.1~-0.2 | 1550°C×2h +0.1~-0.2 |

| Creep rate 0.2MPa×50h % | 1400°C ≤0.8 | 1550°C ≤0.8 |

| Application | combustor, grid room, wind mix chamber | combustor, grid room, wind mix chamber |

![]()

It is widely used in regenerative chamber, combustion chamber,communication pipe and other parts of hot blast stove.

![]()

1.Strong professional:

A:The manager of our company has twenty years working experience in refractory product, technology and trading. He has professional function on a various refractory’ s production materials, process control, quality supervision and package delivery.

B: .Company staff are very familiar with refractory and professional knowledge is very good .

C:Company staff are all college culture level.

2. .Annual supply:

Our company has a dozen cooperative production factories which are better in productive technology and quality management. All the factories has passed ISO9001 quality management system certification. And the annual supply of dense shaped and unshaped refractory product is 100,000-200,000 tons.

3. Annual exports:

Now we have exported more than ten countries , such as Asia ,Europe and South America.The average annual export amount is 10 million Yuan , about $1.6 million.

4. Production equipment:

Production and testing equipments are new, complete and automated or semi- automated. Such modern facilities and equipments have provided the fine technical guarantee for the production and testing.

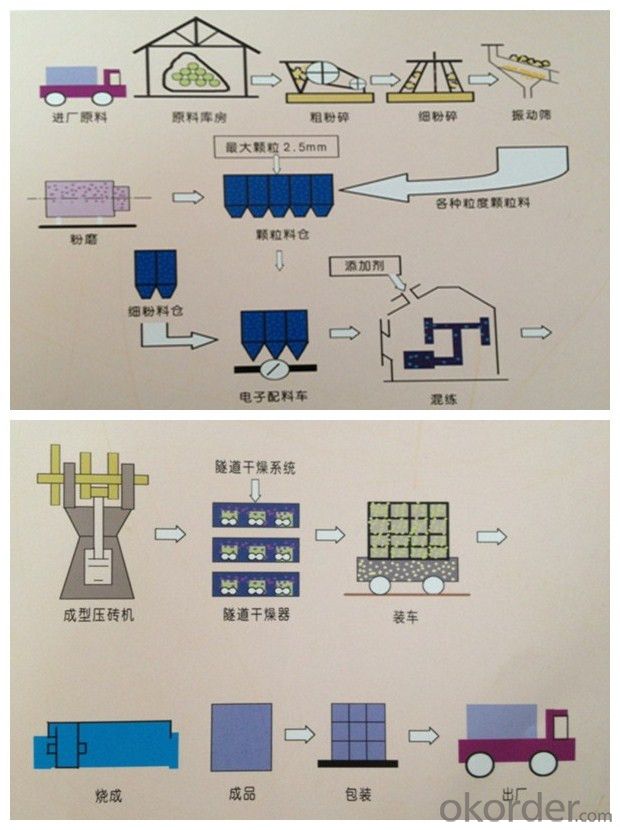

5. Process flowdiagram:

6. Order processing:

After the contract is signed, the relevant responsible person tracked production progress, product quality and product packing aperiodically. During the term of contract sent on time with quantity and quality guaranteed.