Loading Port:Tianjin

Payment Terms:TT OR LC

Min Order Qty:1 set

Supply Capability:30 set/month

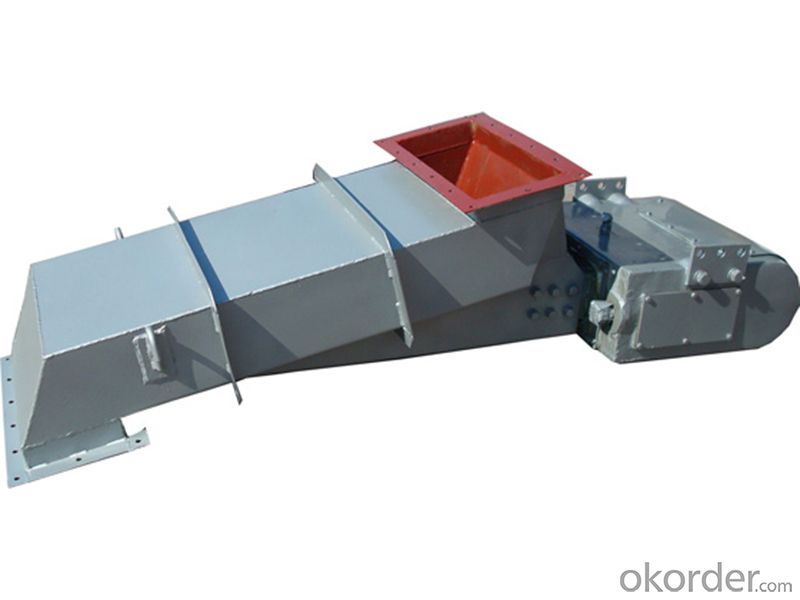

GZ type Electromagnetic vibration feeder

Product overview:

GZ type electromagnetic vibrating feeder used for the materials from the storage bin supply to the receiving device uniformly or quantitatively, is the necessary equipment to implement automated assembly line, divided into open type and closed type two. According to the requirements of the production of motor vibration feeder, hopper, conveyor.

Application:

1. Bulk, granular and powder-like material of the uniform continuous feeding.

2. Belt conveyor, bucket elevator, screening equipment, cement mill, crusher, grinder and the viscosity of the industrial sector of the powder feed material feeding device.

3. Automatic batching, quantitative packaging and etc..

4. Widely used in mining, metallurgy, building materials, coal, light industry, chemical industry, electric power, machinery, food, medicine and other industries.

Advantages:

1.Small size, light weight, simple structure, easy installation.

2.The two-body work in the low critical state, consume less energy.

3.Can instantly change and open and close material flow, to feed the high accuracy.

4.Can achieve centralized control of production processes and automatic control.

5.No lubrication, easy maintenance, low operating costs.

6.Can achieve frequent start and continuous operation.

Technical parameter table:

Model | Model | Capacity (t/h) | Feeding granularity (mm) | Amplit -ude (mm) | Volta-ge (V) | Working current (A) | Effective power (Kw) | |

Horizontal | Capacity | |||||||

Basic type | GZ1 | 5 | 7 | 50 | 1.75 | 220 | 1.34 | 0.06 |

GZ2 | 10 | 14 | 50 | 3 | 0.15 | |||

GZ3 | 25 | 35 | 75 | 4.6 | 0.20 | |||

GZ4 | 50 | 70 | 100 | 8.4 | 0.45 | |||

GZ5 | 100 | 140 | 150 | 12.7 | 0.65 | |||

GZ6 | 150 | 210 | 200 | 1.5 | 380 | 16.4 | 1.5 | |

GZ7 | 250 | 350 | 300 | 24.6 | 2.5 | |||

GZ8 | 400 | 560 | 300 | 39.7 | 4.0 | |||

GZ9 | 600 | 840 | 500 | 47.6 | 5.5 | |||

GZ10 | 750 | 1050 | 500 | 39.4*2 | 4*2 | |||

GZ11 | 1000 | 1400 | 500 | 47.6*2 | 5.5*2 | |||

Closed type | GZ1F | 4 | 5.6 | 40 | 1.75 | 220 | 1.34 | 0.06 |

GZ2F | 8 | 11.2 | 40 | 3.0 | 0.15 | |||

GZ3F | 20 | 28 | 60 | 4.6 | 0.20 | |||

GZ4F | 40 | 50 | 60 | 8.4 | 0.45 | |||

GZ5F | 80 | 112 | 80 | 12.7 | 0.65 | |||

GZ6F | 120 | 168 | 80 | 1.5 | 16.4 | 1.5 | ||