Loading Port:Qingdao

Payment Terms:TT OR LC

Min Order Qty:20 m.t

Supply Capability:3000 m.t/month

1.Product Description of Graphite Electrode for Refining Furnace and Arc Furnace:

Our factory supply graphite powder content in 80-90%, fixed carbon ] [ suitable for steelmaking, casting, lubricant industry.

Graphite powder has chemical stability, and is not affected by strong acid and alkali, less harmful impurities,iron sulfur content is low,high temperature resistance, heat transfer,conductive, lubrication and plasticity,are widely used in casting,battery, carbon products,pencil,and paint, refractory materials,refined carburant,etc.

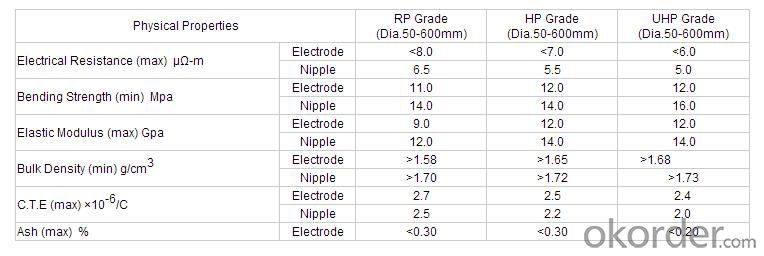

2.Specifications of Graphite Electrode for Refining Furnace and Arc Furnace:

Graphite Electrodes conduct electric current into the furnace. Electric current produces arc in the smelting district, when the temperature increases to about 2000°C, smelting begins. Our series of Graphite Electrodes are applicable to the common furnaces and high power furnaces with high voltage and short arc. G-High Graphite Electrodes are classified into three classes.

3.Features of Graphite Electrode for Refining Furnace and Arc Furnace:

1).Good electrical conductivity

2).High resistance to thermal shock

3).High mechanical strength

4.Applications of Graphite Electrode for Refining Furnace and Arc Furnace:

Used in EAF and LF for steel making, as well as in electric smelting furnace for producing industrial silicon,phosphorus,etc.

5.Technical Data of Graphite Electrode for Refining Furnace and Arc Furnace: