Loading Port:Tianjin

Payment Terms:TT OR LC

Min Order Qty:1 set

Supply Capability:30 set/month

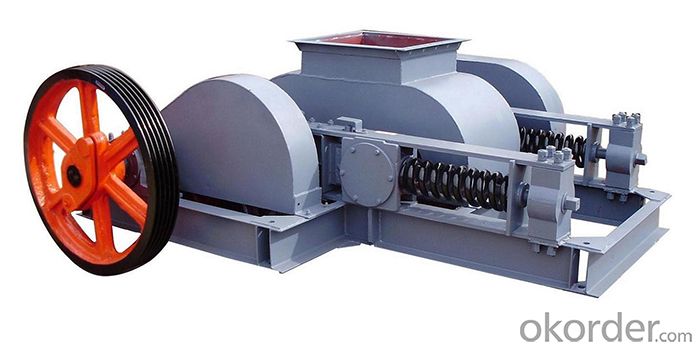

Double toothed roll crusher with high quality

Introduction Overview:

2PGC double tooth roll crusher is double roll type, roller surface shape is coarse tooth roller, tooth roller suitable for brittle and soft material coarse, medium broken. The product with high efficiency, energy saving, environmental protection and other advantages become the preferred equipment to replace imported thermal power plant crushing equipment.

The double tooth roller crusher mainly uses the special wear-resisting tooth roller high speed revolving to split the material to break, has formed the high productivity mechanism.

Has the advantages of small volume, high crushing ratio, low noise, simple structure, convenient maintenance, high productivity, broken material granularity, crushing rate, convenient maintenance, overload protection, sensitive, safe and reliable.

Application:

Double teeth roll crusher for ore, coal, cement, silicate, glass, ceramics and other industries, is suitable for crushing medium hardness following brittle materials, mainly used for ore crushing operations.

Advantages:

1.Crushing ratio of large, broken material moisture without any requirements.

2.Equipped with hydraulic automatic retraction device, can effectively prevent the material on the toothed roller damage.

3.Equipped with intelligent cleaning device, can automatically remove the crusher cavity wall adhesion material.

4.The use of mechanical, electrical, hydraulic and other multiple protection devices and chain devices to prevent power overload, safe and reliable.

5.Tooth roller spacing adopts hydraulic adjustment, tooth roller bearing centralized lubrication.

6.Toothed design optimization, high efficiency and low consumption,a uniform particle.

7.Power consumption is one-half of hammer crusher, energy saving.

8.Through the control of the particle size and adjust roller gap,to change the output.

9.Our company can design and product according to the hardness of the material,t he parameters of roller press are designed by testing the material bearing capacity.

Installation and commissioning

1) to strengthen the mining of iron removal work. Non-crushed material (drill head and other objects) fall into the roll will damage the roller crusher, resulting in a parking accident. So in the roller crusher should be installed before the iron removal device, hammer counter-break.

2) sticky material is easy to plug the crushing space, in the process of blocking the fault should be parking, not in the operation of poking mine.

3) When dealing with the material containing large chunks, it should be noted that large pieces of ore easily squeezed out from the broken space to prevent wounding or damage to equipment.

4) roller crusher running for a long time, due to the large wear on the roll surface, will cause the product size is too small, then pay attention to adjust the discharge port or equipment maintenance.

5) to strengthen the inspection of the equipment, the lubrication of the equipment on time to refuel, to maintain good lubrication equipment.

Maintain

Tooth roller crusher work to pay attention to the following points:

1, in addition to the crusher installed in addition to the mine to remove the iron device. When the non-crushed material (drill bit and other objects) into the roller between the crushing machine will cause damage, resulting in parking accidents.

2, some sticky material will clog the crushing chamber, in the crushing chamber to clean up when the first stop and then clear.

3, tooth roller crusher in the processing of large pieces of material, to prevent large pieces of material from the crushing chamber to fly out to damage the equipment or hurt others.

4, in the tooth roller crusher work for a long time, the roller surface wear and tear, which will cause the material size is too small, so pay attention to adjust the discharge port or equipment maintenance.

5, to fully after the work of the tooth roller crusher to check, to strengthen the lubrication of parts and fasteners fastening work.

Technical parameter table:

Model | Roller diameter(mm) | Roller length(mm) | Maximum feed size(mm) | Discharge size(mm) | capacity (t/h) | Power(KW) | Wight(kg) | size | |

2pgc400×250 | 400 | 250 | 80-100 | 10-50 | 5-20 | 5.5×2 | 1300 | 2400×950×650 | |

2pgc400×400 | 400 | 400 | 180-260 | 10-50 | 15-30 | 7.5×2 | 1800 | 2400×1250×650 | |

2pgc450×500 | 450 | 500 | 200-500 | 15-100 | 30-60 | 7.5×2 | 3800 | 2660×1900×826 | |

2pgc600×750 | 600 | 750 | 300-600 | 20-120 | 60-100 | 11×2 | 7200 | 2780×3065×1310 | |

2pgc600×900 | 600 | 900 | 300-600 | 30-150 | 80-120 | 18.5×2 | 7800 | 4500×1900×1350 | |

2pgc800×1050 | 800 | 1050 | 500-800 | 30-150 | 100-160 | 22×2 | 12600 | 2550×2050×1100 | |

2pgc900×900 | 900 | 900 | 600-900 | 30-200 | 150-200 | 22×2 | 13500 | 2780×4100×1550 | |

2pgc1015×760 | 1015 | 760 | 700-950 | 30-200 | 150-200 | 45×2 | 18800 | 7800×3200×1980 | |

2pgc1200×1500 | 1200 | 1500 | 800-1050 | 30-200 | 200-300 | 55×2 | 52000 | 8010×4500×2050 |