Loading Port:China Main Port

Payment Terms:TT or LC

Min Order Qty:4 Sets set

Supply Capability:500 Sets Per Month set/month

Specifications of Container Homes

1. Container house is a unit house with the size of 6055mm*2435mm*2740mm.

2. Waterproof design of galvanized structure, fireproof and heat insulation of material ensure the house to resist heavy wind load of 0.6KN/m2 and 8 degree seismic intensity.

3. The life span of the house is 20-25 years.

4. The container house adopts EPS, glass wool or rock wool as heat insulation material.

5. All the components are standard and prefabricated with advantage of assembling and disassembling easily. Six skilled workers can finish three modular unit in 8 hours.

6. The container house can be linked freely at length, width and height through the linking kits for bigger structure and different layout.

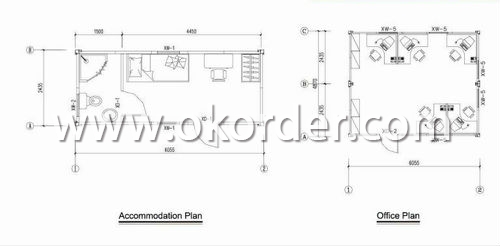

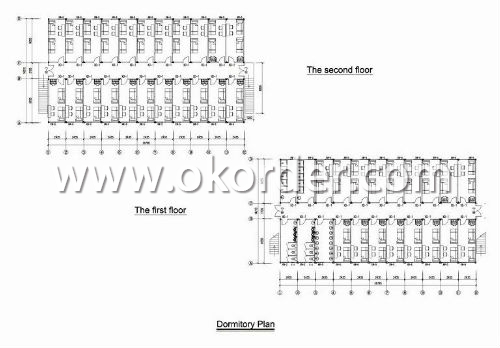

Production and Layout Plan of Container Homes

All of the items are made of steel structure and color steel sandwich panel.

Layout plan of container homes

Packaging & Delivery of Container Homes

According to the quantity, all the parts are packed separately in suitable ways and loaded by containers. 4 sets of standard container houses can be packed together to replace the shipping space of one 20FT container.

Usage/Applications of Prefab House / Modular Homes

*Characters of prefab house/ modular house

1. Structural Reliability: Steel frame structure, safe and reliable, meet Building structure design standards requirements.

2. Good movability performance: jointed with bolts, it can easily disassemble, move and recombine.

3. Attractive appearance: prefab house is designed and installed according to the customer requirements, could with complete indoor facilities, with modern novel design, delicate and elegant, energy-saving and environmental protection, good insulation performance, with warmth and comfortable living environment.

4. Easily installation: Most of the structures of the prefab houses are completed at the factory. Its on-site installation time is short.

5. Flexible layout: Doors and windows may be provided at any position. Interior partitions can be set in any horizontal axis position. In the disassembly and reinstalled process it can be based on customer needs to decrease or increase the number of rooms without changing any of the original material.

*Application of prefab houses/ modular houses

It is widely used in offices, sales offices, classrooms, shops, cafes, exhibition galleries, hospitals, dormitories, canteens, industrial plants, warehouses, parking lots, simple sheds, lean-room, movable guard post, modular villa, site temporary facilities etc.

Installation Steps of Prefab House / Modular Homes

1. Trenching

2. Foundation, brick foundation or concrete foundation

3. Install the steel frame

4. If the structure is multi-layer, to install the prefabricated floor

5. Color plate installation

6. First floor terrace installation

7. Install windows and doors

8. Interior decoration