Loading Port:China Main Port

Payment Terms:TT or LC

Min Order Qty:1000 kg

Supply Capability:100000 kg/month

Description of Chopped Strands for BMC

Chopped Strands for BMC are compatible with unsaturated polyester, epoxy resin and phenolic resins.

The end-use applications include transportation, building & construction, electronic & electrical, mechanical, and light industry

Features of Chopped Strands for BMC

Low viscosity and excellent flowability of the BMC paste

Low static and low fuzz, fast and good dispersion in resins

Good processing and excellent mechnical properties

Specification of Chopped Strands for BMC

Product No. | Nominal Chopped Length(mm) | Product Features | Resin Compatibility | Applications |

562A | 3,6,9,12 | Extremely low resin demand, delivering low viscosity to BMC paste | Unsaturated polyester, vinyl ester and epoxy resins | Suitable to manufacture high fiberglass loading products with complex structure and superior color, for example, ceiling tiles and lampshade. |

552B | 3,6,9,12 | High impact strength; High LOI rate | Unsaturated polyester, vinyl ester and epoxy resins | Used in automotive parts, civilian electrical switches, sanitary ware and other products requiring high strength. |

558 | 3,6,9,12 | Good strand integrity, low static and fuzz, Fast and uniform distribution in resins, excellent mechanical and processing properties | Rubber and Phenolic resin | Used to manufacture various brake shoe facings, clutch facings, and friction plates. |

Storage of Chopped Strands for BMC

Unless otherwise specified, fiberglass products should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15 Deg.C-35 Deg.C and 35%-65% respectively.

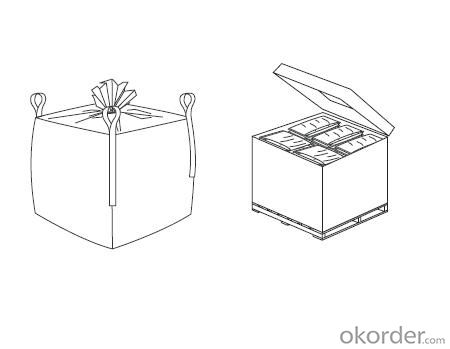

Photo of Chopped Strands for BMC