Loading Port:China main port

Payment Terms:TT OR LC

Min Order Qty:1 unit

Supply Capability:10000 unit/month

Introduction

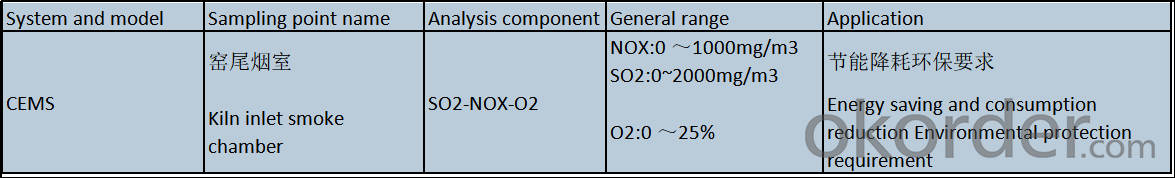

CEMS Continuous Flue Gas On-line Detecting System uses flue gas ultraviolet analysis, back scattering smoke concentration measurement, gas temperature, pressure and flow integration flue gas parameter measurement and computer network communication technology to realize the on-line continuous monitoring of pollutant emission concentration and total emission amount of the stationary pollution source. Meanwhile, the system is technically modified due to different kinds of coal, big change of coal quality, high emission concentration of pollutant and high humidity of flue gas. It is also designed and finalized according to the national standard. The system not only uses emission compliance monitoring and sewage disposal metering, but also operation state inspection and fault diagnosis of equipment (de-dusting, de-sulfuration and boiler burning condition).

Technical indexes

Smoke quality concentration: 0~500mg/m3

Sulfur dioxide concentration:0~2000mg/m3

Nitric oxide concentration:0~1000mg/m3

Flue gas flow speed: 0~40m/s

Oxygen content: 0~25%

Rue gas temperature: 0~300℃

Flue gas pressure: -10~+10KPa

Characteristics

1. It has technical modification that is suitable for China's national conditions, with strong system compatibility. And it is improved technologically in view of the special conditions in China such as various kinds of coal, large variation of coal quality, high pollutant emission concentration and high flue gas humidity.

2. The system maintenance period is largely expanded with good system maintainability, simple structure, mutual independence and easy maintenance.

3. Devices such as probe and dust meter can be set in the system software for automatically and regularly calibrating the cycle, without need of manual intervention.

4. It's provided with all-weather expert support measures, which can carry out data communication with system through GPRS network for remote error diagnosis, ensuring thus the system operation.

5. It's provided with technology measures which can improve the system reliability. It possesses strong function of data collection and processing, multi-group analog and switch input and output interfaces, which can be connected to several probes. It can realize the field bus connection to make the system operation easier and more flexible, as well as cost saving. Through the connection with the local environmental department by Internet, it transmits the flue gas emission data timely to the remote end which requires data.

Company Introduction

Hefei GoodTimes Automation Co., Ltd. is a technique oriented state-level high-tech enterprise, transformed from Hefei Jinshan Science and Technology Industrial Company organized on the basis of automation institute of Hefei Cement Research & Design Institute Corporation Ltd. under of CNBM.It was awarded the Anhui Industrial Design Center, Hefei Enterprise Technology Center, Hefei Brand demonstration Enterprise, Hefei Engineering Technology Research Center. The core team is composed of the automation laboratory of construction institute. It is a scientifific and technological enterprise with a long history and strong technical strength, which integrates scientifific research and development, equipment manufacturing, engineering settings, and technical service.The company has established a perfect quality assurance system, which has passed the authentication of ISO9001 quality management system certifification,ISO14001environment management system certifification,OHSAS18001 occupational health & safety management system certifification, level 3 work safety standardization and Certifificate for China Compulsory product certifification.It is engaged and specialized in the development of the whole series of material measurement, process control, factory power distribution and electric control, monitoring and control devices for cement production as well as their manufacturing and services. The company has inherited innovative development experience from the core team for more than 60 years. It is staffed with a professional team with fifirm grasp of the latest technology and rich practical experience. In product development, production and services, it adheres to the business concept of “Customer-centered, innovation-driven, aiming at the win-win”. The company will continue to make customers feel “carefree, assured and content"