Loading Port:Shanghai

Payment Terms:TT OR LC

Min Order Qty:1 unit

Supply Capability:30 unit/month

Copper Extrusion Machine for all series

- The History of the copper extrusion machine

The Conform Extrusion/Copper Extrusion Machine is a newly-developed [Metal Plastic Processing Technology] .

- The Application of the copper extrusion machine

To produce:

l Copper bus bar from copper extrusion machine

l Copper flat wire from copper extrusion machine

l Copper round wire from copper extrusion machine

l Shaped copper material under approximate any size… …

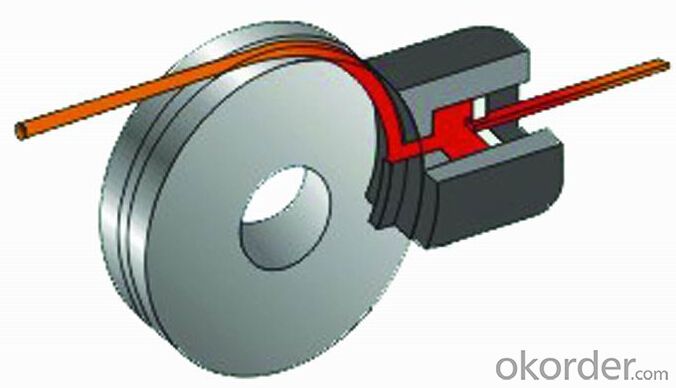

- The theory of the copper extrusion machine

Tooling and Steps of the conform theory:

[1] the continuously-rotating extrusion wheel,

[2] the frictional force between the wheel groove,

[3] continuous rod’s pulling,

[4] the plastic deformation happens inner the die chamber.

[5] And finally the output is extruded out.

For continuous cladding process, two aluminum feed-stocks are employed, and the chamber is fitted on the upper position of the extrusion wheel. The core wire or steel wire is fed in the tangential direction, and the aluminum feed-stocks are formed into the aluminum pipe through the chamber, then the aluminum pipe wraps around the core wire to be formed into the cladding or sheathing product.

The revolving extrusion wheel is driven by a motor, and it guides the feedstock to enter the wheel groove. The feedstock is dragged into the chamber by the friction between the wheel groove and feedstock. The friction generates high temperature and heavy pressure, under the high temperate and pressure, the metal is formed into the pipe or profile through a die.

Advantages of copper extrusion machine

1. Lower energy consumption

2. Better microstructure

The continuous extrusion method use oxygen free copper rod and has natural closed space during extruding and can easily produce oxygen free copper bar. It is impossible for the traditional process.

3. Higher material using ratio

The excess stock of traditional extrusion process and waste heads after drawing process cause low utilization ratio of material

4. Lower labor and processing cost

The traditional process needs more manpower and great worker's labor intensity,

Tech. parameters of production line | ||||

Type | SNLD350 | SNLD400 | SNLD500 | |

Nominal Diam. of extrusion wheel (mm) | 350 | 400 | 500 | |

Material type (Up-ward oxygen free copper rod) | Pure copper /brass copper | Pure copper /brass copper | Pure copper /brass copper | |

Max. product width (mm) | 80 | 170 | 240 | |

Max. sectional area (mm²) | 600 | 2000 | 3800 | |

Production capacity (kg/h) | 860 | 1300 | 2000 | |