Loading Port:China main port

Payment Terms:TT OR LC

Min Order Qty:1 set

Supply Capability:100 set/month

Profile

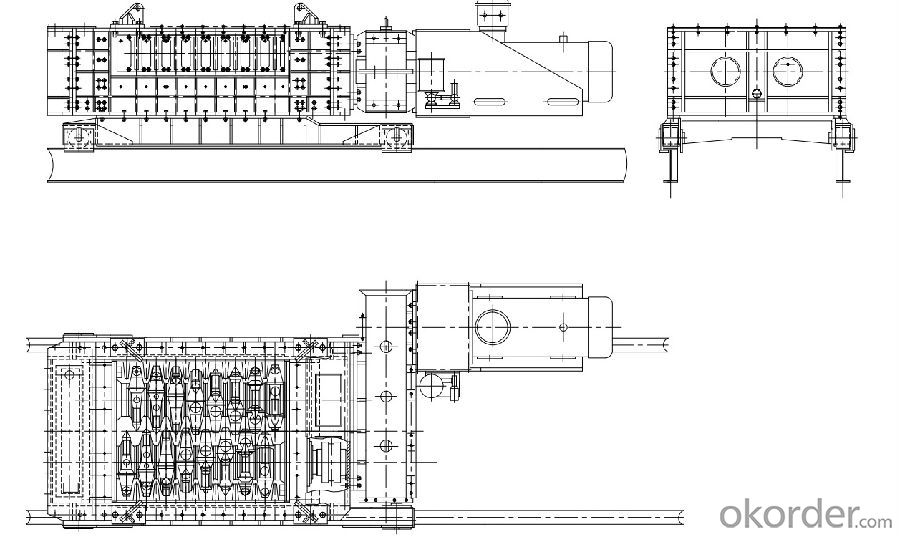

The two motors of the 2PLF Model Grading Tooth Roller Crusher pass the power to a pair of tooth rollers through the reducer, and drive them to rotate in opposite directions, so as to realize the screening of small pieces of material and the function of extrusion, shearing and crushing of large materials. The 2PLF Model Grading Tooth Roller Crusher is mainly used for coal, coke and other hard material of coarse, medium and fine crushing operations, has the characteristics of wide adaptability and has better adaptability for high viscosity, moisture of material, can be widely used in crushing coal, metallurgy, building materials, chemical industry.

Features

The 2PLF Model Grading Tooth Roller Crusher is small in volume and light in weight.

The broken teeth adopt corresponding engineering materials according to the different hardness of materials.

The bearing of the 2PLF Model Grading Tooth Roller Crusher adopts centralized lubrication method.

The PLC control system is adopted, the network interface can be kept for real time monitoring with the system's feeding and discharging.

Components

The 2PLF Model Grading Tooth Roller Crusher mainly consists of a motor, a fluid coupling, a reducer, a walking device, a left and right mounting, a tooth roller, a side plate, a centralized lubrication system and so on.

-Motor

The ordinary motor is used in general. When used in a coal mine or a large dust environment, an anti electric motor should be selected (used in the period of validity of a safety certificate).

-Fluid Coupling

The fluid coupling is used to connect the motor to the reducer, it can reduce the shock and vibration when starting, and also protect the equipment. Water medium fluid coupling is used in underground

-Reducer

. The input shaft of the reducer is connected with fluid coupling, and its output shaft is connected to the tooth roller through a gear coupling.

-Travelling Mechanism

The travelling mechanism is used to support the whole crusher. For the convenience of equipment maintenance, when it leaves the working position, it has four walking wheels, which can roll on the guide rail and drive the crusher to move on the guide rail.

Coarse crushing classified-type tooth roller crusher 140 series

Model specification | 2PLF-140/150 | 2PLF-140/200 | 2PLF-140/250 | 2PLF-140-300 |

(mm) Size of input granularity | ≤1500 | ≤1500 | ≤1500 | ≤1500 |

(mm) discharging granularity | ≤300 | ≤300 | ≤300 | ≤300 |

(t/h) Handling capacity | ≤2500 | ≤3800 | ≤4600 | ≤5500 |

Coarse crushing classified-type tooth roller crusher 120 series

Model specification | 2PLF-120/150 | 2PLF-120/200 | 2PLF-120/250 | 2PLF-120-300 |

(mm) Size of input granularity | ≤1200 | ≤1200 | ≤1200 | ≤1200 |

(mm) discharging granularity | ≤300 | ≤300 | ≤300 | ≤300 |

(t/h) Handling capacity | ≤1500 | ≤2000 | ≤2700 | ≤3300 |

Intermediate crushing classified-type tooth roller crusher 100 series

Model specification | 2PLF-100/160 | 2PLF-100/200 | 2PLF-100/250 |

(mm) Size of input granularity | ≤700 | ≤700 | ≤700 |

(mm) discharging granularity | 50-150 | 50-150 | 50-150 |

(t/h) Handling capacity | 280-850 | 350-1000 | 500-1500 |

Intermediate crushing classified-type tooth roller crusher 80 series

Model specification | 2PLF-80/150 | 2PLF-80/200 | 2PLF-80/250 | 2PLF-80/300 |

(mm) Size of input granularity | ≤550 | ≤550 | ≤550 | ≤550 |

(mm) discharging granularity | 50-150 | 50-150 | 50-150 | 50-150 |

(t/h) Handling capacity | 200-600 | 260-750 | 300-1000 | 400-1150 |

Intermediate crushing classified-type tooth roller crusher 60 series

Model specification | 2PLF-60/70 | 2PLF-60/120 | 2PLF-60/150 | 2PLF-60/200 |

(mm) Size of input granularity | ≤400 | ≤400 | ≤400 | ≤400 |

(mm) discharging granularity | 50-150 | 50-150 | 50-150 | 50-150 |

(t/h) Handling capacity | 80-240 | 200-600 | 250-700 | 300-800 |

-Left and Right Mounting

The left and right mounting are made of cast steel to support two tooth rollers.

-Tooth Roller

The tooth roller is the working part of the crusher. The gear seat is installed on the tooth roll shaft, and the broken gear is installed on the gear seat. When the material enters the crushing chamber, the material is sieved and broken by the two tooth roller. The broken gear are made of wear-resistant steel and spirally arranged. The tooth roller is equipped with synchronous gear, which can adjust the relative position of the two tooth roller.

-Side Plate

The side plate is welded and assembled by the steel plate, it is combined with the left and right mounting. The side plate is loaded with side tooth plate which can play the sieving actoion.

-Centralized Lubrication System

The centralized lubricating system adopts lubricating grease pump to lubricate the four sets of bearings on the two gear rollers and synchromesh gear.

Working Principle

The broken gear of the 2PLF Model Grading Tooth Roller Crusher is helical arranged on the tooth roller, and the relative motion of the two rolls, such as the rotating sieves, will be smaller than the grain size of the material, and the bulk material is broken. At the same time, the fixed center distance and special tooth profile design can be used to ensure the product granularity strictly. Therefore, it has the double effects of crushing and screening. In a certain range, the breaking and screening work can be completed alone, without the need for the screening equipment.

In order to give full play to the efficacy of fragmentation, the 2PLF series classification crusher is aimed at different materials, the design has positive and negative two kinds of steering. In general, the content of coal is greater than the product size of the material is dominant, roll the forward rotation, can improve the crushing efficiency; On the other hand, should be used to reverse crushing product size less than coal large screen penetration, only greater than the size of coal was broken, so as to achieve good crushing effect.

The 2PLF series classification crusher adopts the triangle belt leading large belt wheel drive in the transmission form, the transmission structure is simple and the failure rate is low. Because of the large belt wheel has the function of energy storage, it makes the motor power required is smaller than that of the direct transmission. Double teeth roll crusher adopts the counter rotating mode, the broken tooth adopts bullets type, hard of surfacing is high in strength, high in crushing efficiency and easy to repair after wear.

FAQ

1.How many transmission structures are there in the 2PLF Model Grading Tooth Roller Crusher?

-It has single motor drive and double motor drive.

2.Can the 2PLF Model Grading Tooth Roller Crusher automatically achieve the protection of over iron?

-When the equipment is over iron phenomenon, the two groups of crushing rolls will reverse the material which is difficult to break out, so as to achieve the protection of iron.

3.How to implement the maintenance of each lubricating point in the equipment?

-The 2PLF Model Grading Tooth Roller Crusher is equipped with automatic lubricating device, and each lubricating point is regularly monitored and refueling.